Preparation method and application of poly (R)-3-hydroxybutyrate

A technology of hydroxybutyrate and reaction, which is applied in the field of preparation of poly-3-hydroxybutyrate, can solve the problems of wide molecular weight distribution, difficult control of basic chemical parameters such as product molecular weight, and many times of washing, so as to achieve molecular weight grading and regulation, to achieve the maximum utilization of resources, and the effect of low requirements on production equipment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

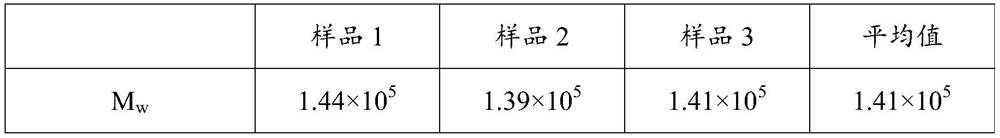

Embodiment 1

[0051] A preparation method of medical grade poly(R)-3-hydroxybutyrate and its incidental product (R)-3-hydroxybutyric acid, comprising the following steps:

[0052] Get 50g of PHB crude product powder (purity is 89%, number-average molecular weight Mn is 250,000, molecular weight dispersity 2.0) is added in the three-necked flask of 500mL, adds 150mL absolute ethanol, stirs, boils and refluxes at 80 ℃ for 6 hours. Add 200 mL of purified water, heat up to 90 °C, open the bottle, keep the temperature for 1 hour, evaporate the ethanol, add 100 mL of purified water; then cool down to 55 °C, under stirring, use 0.3mol / L hydrogen The sodium solution adjusted the pH of the system to 9.5. Then 0.55% by weight of protease and 0.55% by weight of lipase were added. The flask was fixed on an ultrasonic device for sonication. Ultrasonic related parameters are, temperature 55 ℃, power 1.20W / cm 2 , the ultrasonic time is 12 hours.

[0053] After sonication, it was naturally cooled to ro...

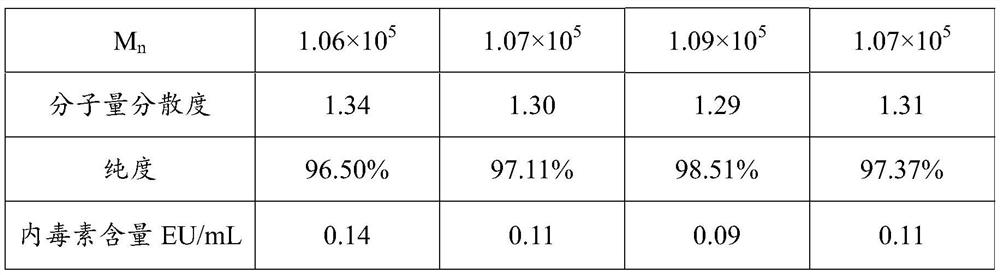

Embodiment 2

[0063] A preparation method of medical grade poly(R)-3-hydroxybutyrate and its incidental product (R)-3-hydroxybutyric acid, comprising the following steps:

[0064] Get 50g of PHB crude product powder (purity is 90%, number-average molecular weight Mn is 350,000, molecular weight dispersity 1.9), add in 500mL there-necked flask, add 150mL absolute ethanol, stir, boil and reflux at 80 DEG C for 6 hours. Then 200 mL of purified water was added, the temperature was raised to 90°C, the bottle mouth was opened, and the temperature was kept for 1 hour. After ethanol was evaporated, 100 mL of purified water was added, and the temperature was lowered to 55°C. With stirring, the pH of the system was adjusted to 9.5 with 0.3 mol / L sodium hydroxide solution, and then 0.55% (weight percent) protease and 0.55% (weight percent) lipase were added. The flask was fixed on an ultrasonic device for sonication. Ultrasonic related parameters are, temperature 55 ℃, power 1.20W / cm 2 , the ultraso...

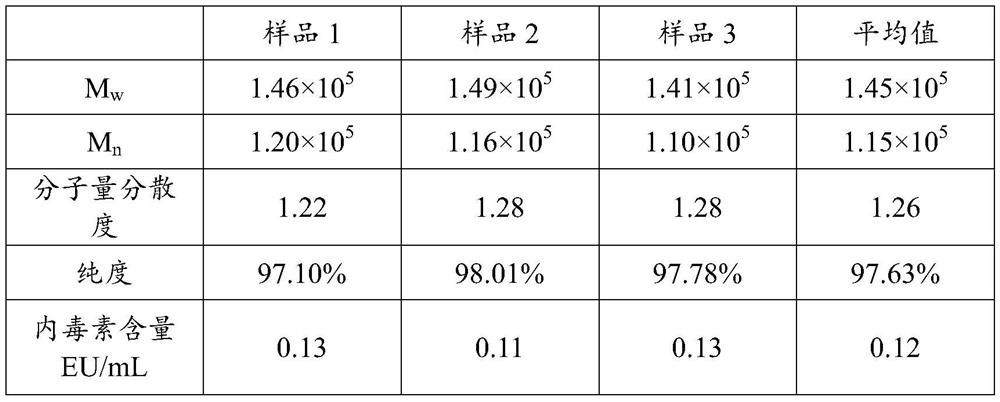

Embodiment 3

[0074] A preparation method of medical grade poly(R)-3-hydroxybutyrate and its incidental product (R)-3-hydroxybutyric acid, comprising the following steps:

[0075] Get 50g of PHB crude product powder (purity is 89%, number-average molecular weight Mn is 250,000, molecular weight dispersion 2.0), add in 500mL there-necked flask, add 150mL absolute ethanol, stir at 80 DEG C under boiling reflux for 6 hours. Then 200 mL of purified water was added, the temperature was raised to 90°C, the bottle mouth was opened, and the temperature was kept for 1 hour. After ethanol was evaporated, 100 mL of purified water was added, and the temperature was lowered to 55°C. Under stirring, the pH value of the system was adjusted to 9.5 with 0.3 mol / L sodium hydroxide solution, and then 0.55% (weight percent) protease and 0.55% (weight percent) lipase were added. The flask was fixed on an ultrasonic device for sonication. Ultrasonic related parameters are, temperature 55 ℃, power 1.20W / cm 2 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com