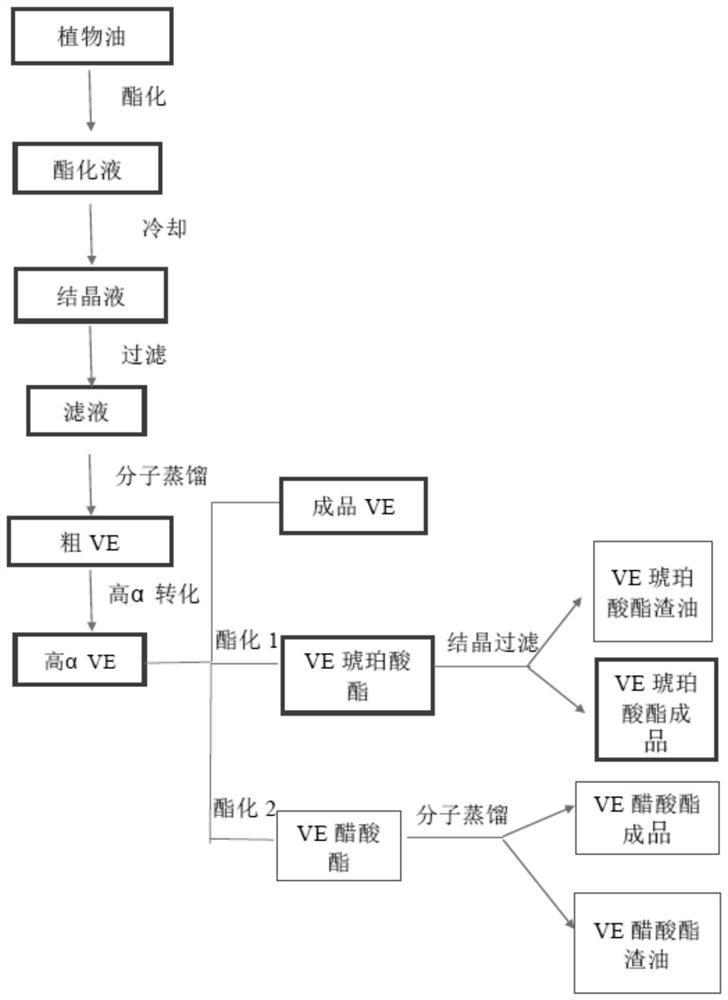

Method for extracting natural vitamin E from byproduct residual oil

A technology of natural vitamins and vitamins, applied in organic chemistry methods, organic chemistry, organic anion exchangers, etc., can solve problems such as high environmental pollution risks, complex production equipment, and high operating vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Take 1000 g of gel-type strongly basic anion exchange resin HZ-202, fully swell with 1600 mL of 95% ethanol aqueous solution, and then load it into a chromatography column, and elute the column with 2000 mL of 95% ethanol to balance the column.

[0083] Take 150 g of VES residual oil sample (from Fengyi Biotechnology Jiangsu Co., Ltd.), add 3 times the mass of 95% ethanol aqueous solution to dissolve, and load the sample. 2 -95% ethanol aqueous solution for elution, the eluent was continuously collected and detected by thin layer chromatography (TLC), the developing solvent was n-hexane-diethyl ether-acetic acid 8:2:0.2, and the eluent fraction containing tocopherol was collected, After the combination, the mixture was concentrated under reduced pressure to constant weight at 50° C. to obtain 107.99 g of vitamin E product 1.

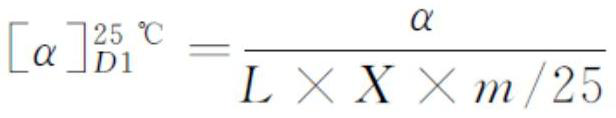

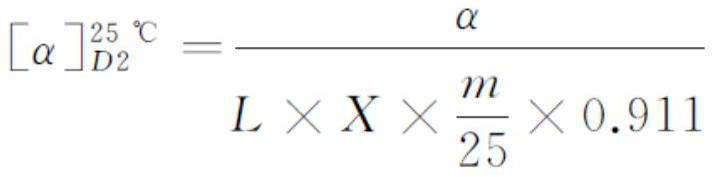

[0084] After testing, the VES content in the sample before the resin column was 56.31wt%, the VE content was 6.11wt%, and the specific optical ro...

Embodiment 2

[0086] Take 1000 g of gel-type strongly basic anion exchange resin HZ-202, fully swell with 1600 mL of 95% ethanol aqueous solution, and then load it into a chromatography column, and elute the column with 2000 mL of 95% ethanol to balance the column.

[0087] Take 200 g of VEA residual oil sample (from Fengyi Biotechnology Jiangsu Co., Ltd.), add 3 times the mass of 95% ethanol aqueous solution to dissolve, and load the sample. The chromatographic column is first eluted with 2500 mL of 95% ethanol aqueous solution, and then 4000 mL of saturated CO 2 -95% ethanol aqueous solution for elution, the eluent was continuously collected and detected by thin layer chromatography (TLC), the developing solvent was n-hexane-diethyl ether-acetic acid 8:2:0.2, and the eluent fraction containing tocopherol was collected, After the combination, it was concentrated under reduced pressure at 50° C. to constant weight to obtain 111.90 g of vitamin E product 2.

[0088]After testing, the VEA con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific rotation | aaaaa | aaaaa |

| Specific rotation | aaaaa | aaaaa |

| Specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com