Preparation method of thermal barrier coating with composite structure

A technology of thermal barrier coating and composite structure, which is applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problems of complex process, high cost, poor shielding effect, etc., and achieve high design flexibility , Improve the effect of resisting foreign object erosion and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

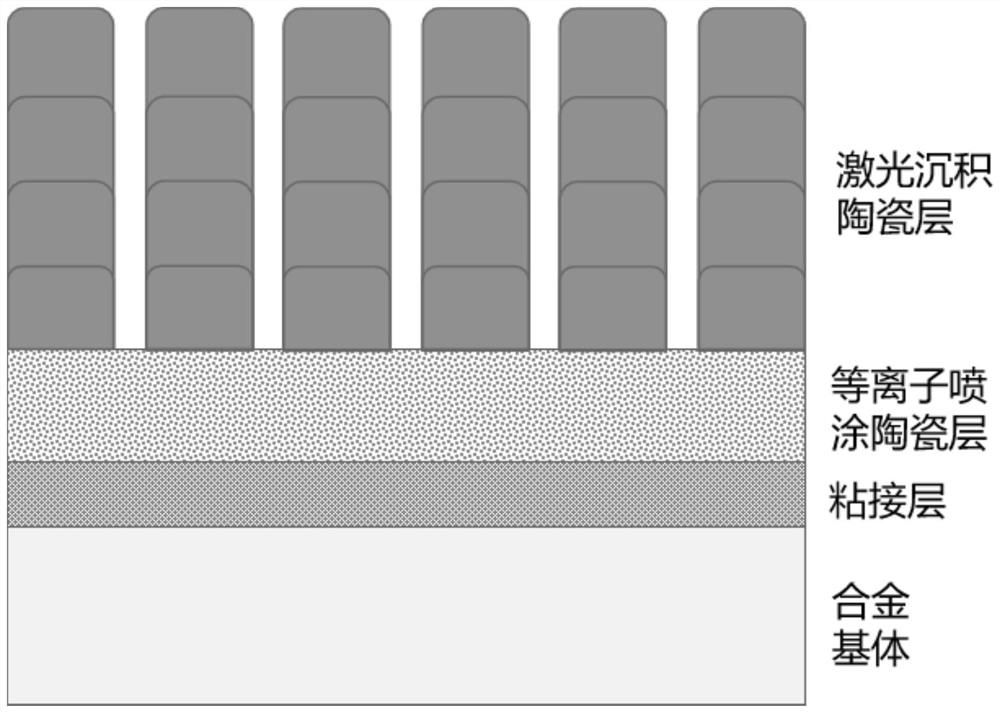

[0027] The present invention proposes a preparation method of a thermal barrier coating with a composite structure. The thermal barrier coating can be deposited on the surface of a superalloy part coated with an adhesive layer, such as NiPtAl, MCrAlY, etc. which are currently mainstream. The layered ceramic layer material can use the current conventional fluorite structural materials (such as yttria-stabilized zirconia (YSZ)), pyrochlore structural materials (such as gadolinium zirconate, lanthanum ceric acid), etc., using plasma spraying combined with laser coaxial transmission. Powder deposition is realized, which specifically includes the following steps:

[0028] S1, coating an adhesive layer on the surface of the alloy substrate; the adhesive layer can be prepared by plasma spraying, low pressure plasma spraying, supersonic spraying, EB-PVD, vapor aluminizing deposition and chemical vapor deposition.

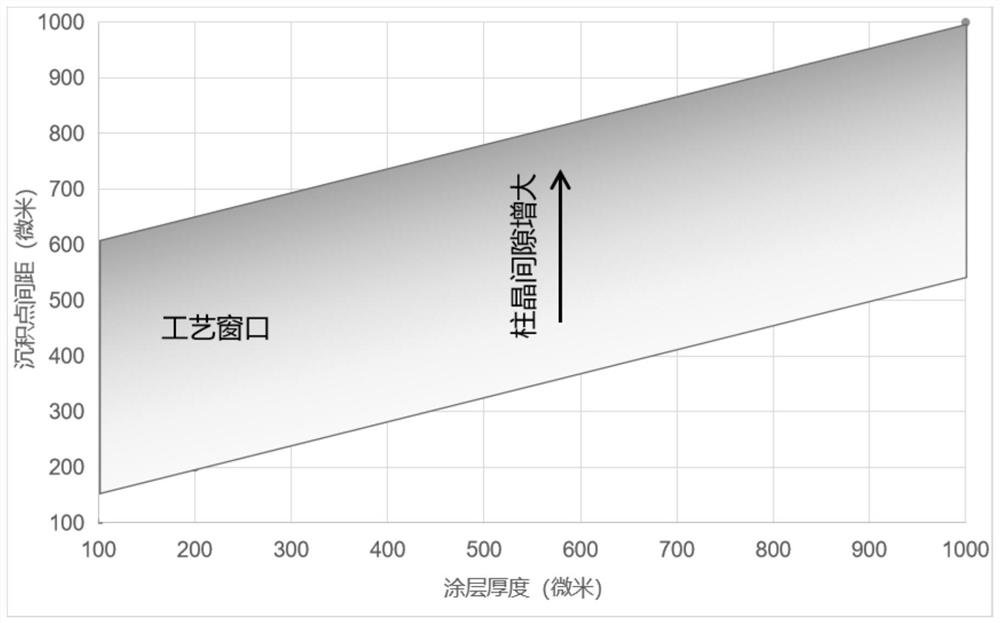

[0029] S2, the plasma sprayed lower layered structure, and the thickne...

Embodiment 1

[0038] A preparation method of thermal barrier coating with composite structure adopts the following steps:

[0039] S1, coating the NiCoCrAlY bonding layer on the surface of the alloy substrate;

[0040] S2, plasma sprayed lower layered structure, using 8YSZ material;

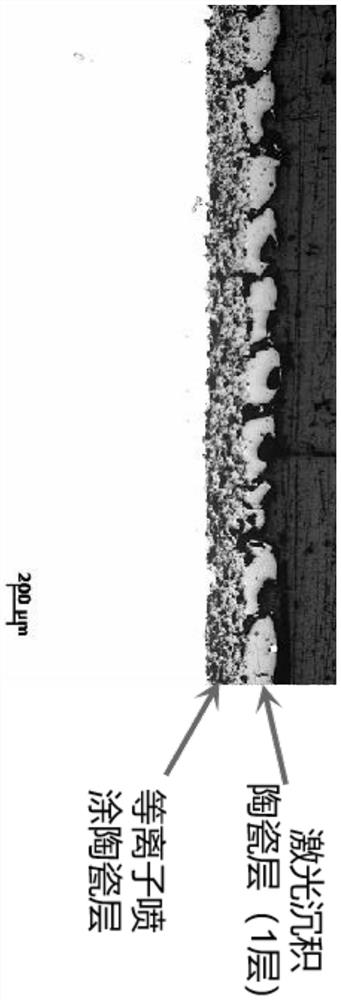

[0041] S3, the upper layer columnar structure is deposited by laser coaxial powder feeding, and the number of deposition layers is one layer. First, control the movement of the robotic arm to adjust the positioning and focusing size of the laser head on the surface of the coated workpiece; use 15-45μm spherical granulation 8YSZ powder, 4-way coaxial powder feeding, and the carrier gas volume is 7L / min; turn on the pulsed laser and continuously feed powder and ensure that the powder is fed into the laser beam; the laser beam power is 100W, and the beam spot size is 200μm; the robotic arm is controlled to make the laser head move continuously on the surface of the workpiece to achieve columnar coating depositio...

Embodiment 2

[0044] A preparation method of thermal barrier coating with composite structure adopts the following steps:

[0045] S1, coating the NiPtAl bonding layer on the surface of the alloy substrate;

[0046] S2, plasma sprayed lower layered structure, using 8YSZ material;

[0047] S3, the upper layer columnar structure is deposited by laser coaxial powder feeding, and the number of deposition layers is 3 layers. First control the movement of the robotic arm, adjust the positioning and focusing size of the laser head on the surface of the coated workpiece; use 15-45μm spherical granulation Gd 2 Zr 2 O 7 Powder, 4-way coaxial powder feeding, the carrier gas volume is 5L / min; Turn on the pulsed laser, continuously feed powder and ensure that the powder is sent into the laser beam; The laser beam power is 150W, and the beam spot size is 250μm; The head continuously moves on the surface of the workpiece to realize the deposition of the columnar coating, and the laser pulse output is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com