Preparation method of copper pyrophosphate with catalytic activity

A copper pyrophosphate, catalytic activity technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of poor catalytic activity of copper pyrophosphate, unsuitable for catalyst use, etc., to achieve small secondary pollution , The effect of mild preparation conditions and mature process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of copper pyrophosphate with catalytic activity comprises the following steps:

[0030] (1) According to the mole ratio of Cu to P of 1.2, dissolve 12 g of copper sulfate pentahydrate in 40 mL of distilled water and 4.6 g of ammonium dihydrogen phosphate in 29 mL of distilled water, and then mix and stir the copper sulfate solution and the ammonium dihydrogen phosphate solution. uniform, forming a turbid liquid;

[0031] (2) stirring above-mentioned turbid liquid, and dripping nitric acid solution simultaneously, until precipitation disappears, obtains blue clear solution;

[0032] (3) The above blue solution was dried in a drying oven at 85°C for 12h, and ground to obtain blue powder;

[0033] (4) The above blue powder is calcined at a high temperature of 600° C. for 2 hours, and after cooling, copper pyrophosphate with catalytic activity and high purity is obtained.

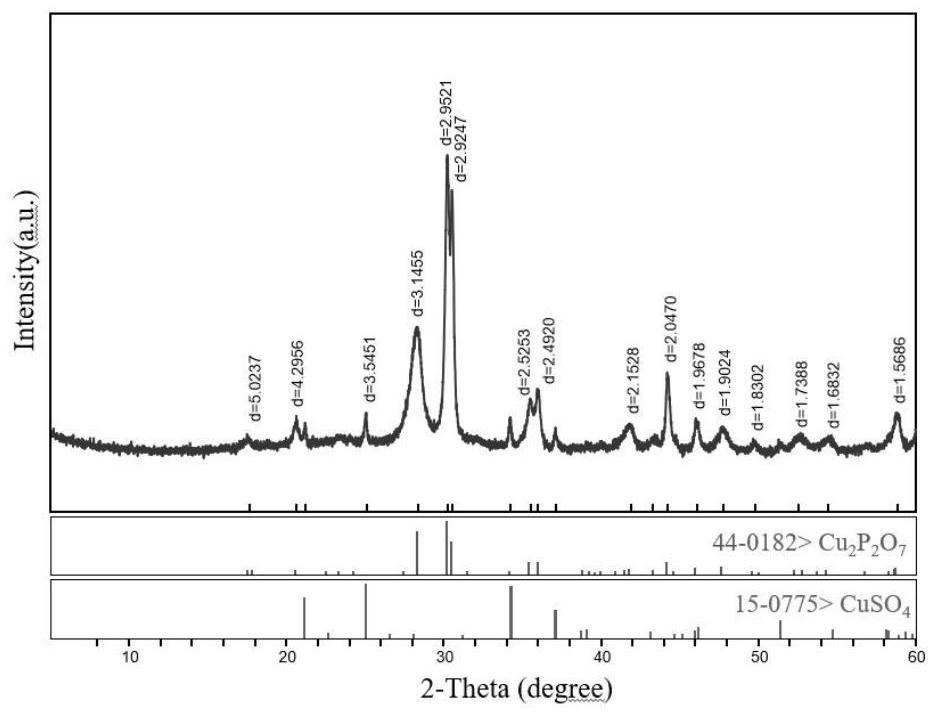

[0034] figure 1 is the XRD pattern of copper pyrophosphate, from figure 1 ...

Embodiment 2

[0036] The preparation method of copper pyrophosphate with catalytic activity comprises the following steps:

[0037] (1) According to the mole ratio of Cu to P of 1, dissolve 9.7 g of copper nitrate trihydrate in 33 mL of distilled water and 4.6 g of ammonium dihydrogen phosphate in 29 mL of distilled water, respectively, and then mix the copper nitrate solution with the ammonium dihydrogen phosphate solution. Stir well to form turbid liquid;

[0038] (2) stirring the above-mentioned turbid liquid, and adding dilute sulfuric acid solution dropwise at the same time, until the precipitation disappears to obtain a blue clear solution;

[0039] (3) The above blue solution was dried in a drying oven at 105°C for 6 hours, and ground to obtain a blue powder;

[0040] (4) The above blue powder is calcined at a high temperature of 650° C. for 1.5 hours, and after cooling, copper pyrophosphate with catalytic activity is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com