Nano-clay calcium hydroxide composite material for repairing and reinforcing as well as preparation and application of nano-clay calcium hydroxide composite material

A nano-clay and calcium hydroxide technology, applied in the field of stone cultural relic protection, can solve the problems of slow maintenance, low solubility, poor permeability, etc., and achieve the effects of uniform effect, no durability and high retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

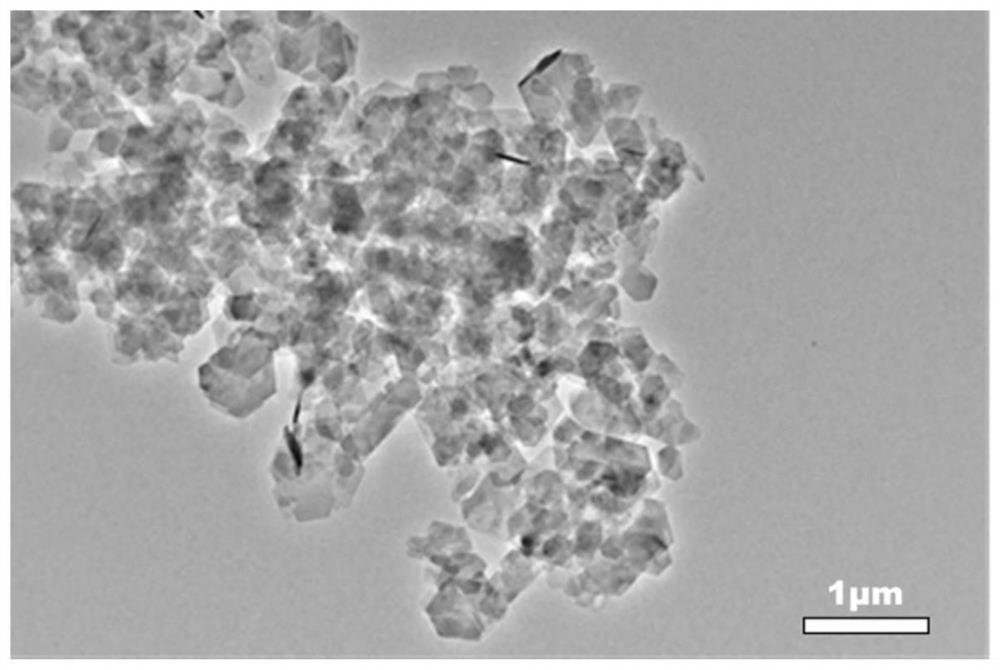

[0033] (1) Nanometer metakaolin is obtained by calcining nanometer kaolin at 750°C for 5 hours. The obtained metakaolin is immersed in deionized water containing 5 wt % isopropanol to disperse uniformly, and the mass ratio of the solution to nano-metakaolin is 10:1. Then, to 100 ml of the nano-metakaolin dispersion liquid, 30 ml of 0.05M calcium acetate and 30 ml of 0.10M sodium hydroxide aqueous solution were successively added, and the reaction was carried out at room temperature for 10 minutes. The solid product was obtained by filtration and separation, washed three times with deionization, and dried at 100° C. to obtain nano-metakaolin calcium hydroxide composite powder.

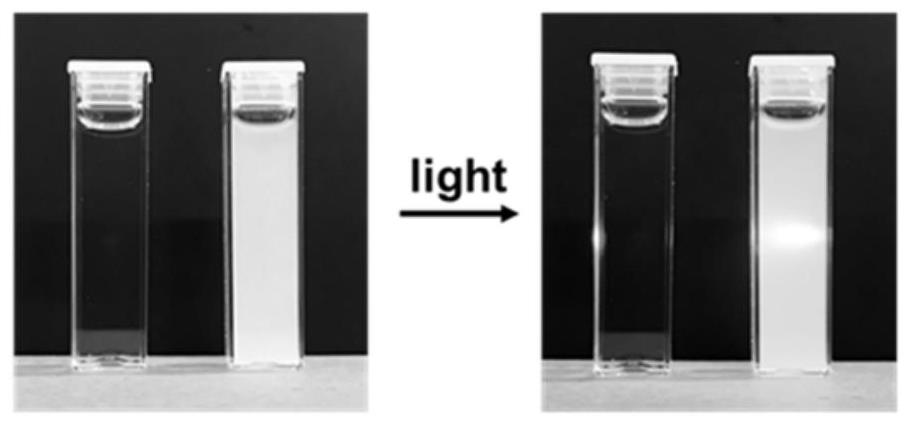

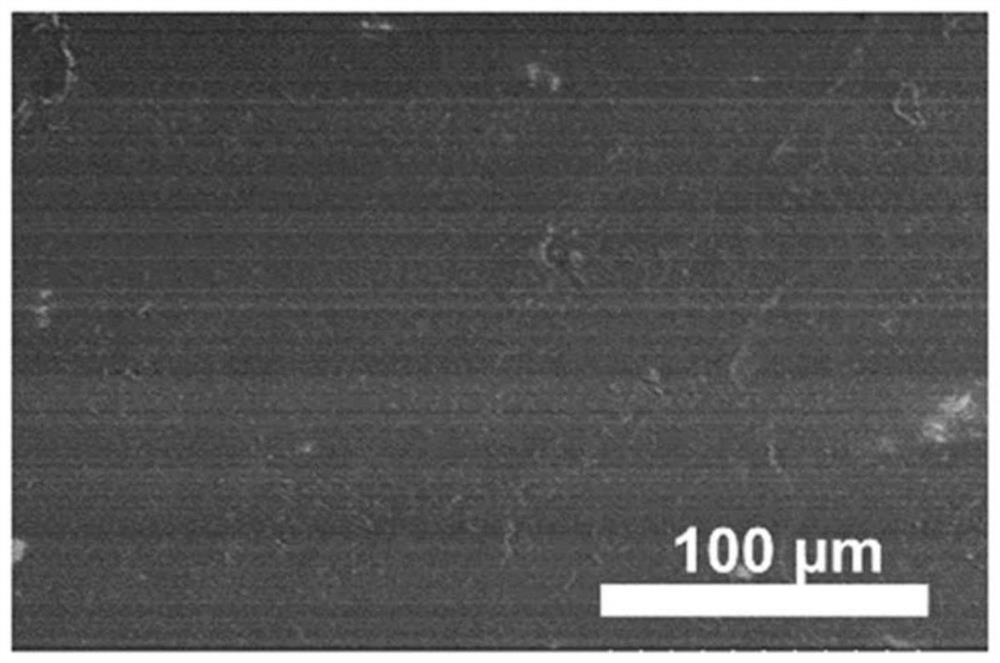

[0034] (2) Disperse in isopropanol with a mass ratio of 10wt% to prepare a repairing protection solution. Under the conditions of 25°C and 45% humidity, the sandstone stones were treated 3 times by the spray coating method and maintained for 28 days.

[0035] (3) After treatment, the penetration depth...

Embodiment 2

[0037] (1) Nanometer metakaolin is obtained by calcining nanometer kaolin at 750°C for 5 hours. The obtained metakaolin was immersed in deionized water containing 5wt% n-propanol to disperse uniformly, and the mass ratio of the solution to nano-metakaolin was 20:1. Then, to 100 ml of the nano-metakaolin dispersion liquid, 30 ml of 0.08M calcium acetate and 30 ml of 0.20M aqueous ammonia solution were successively added, and the reaction was carried out at room temperature for 10 minutes. The solid product was obtained by filtration and separation, washed three times with deionization, and dried at 100° C. to obtain nano-metakaolin calcium hydroxide composite powder.

[0038] (2) Disperse in isopropanol with a mass ratio of 5wt% to prepare a repairing protection solution. Under the conditions of 25°C and 45% humidity, the sandstone stones were treated 3 times by the spray coating method and maintained for 28 days.

[0039] (3) After treatment, the penetration depth is 16.8mm,...

Embodiment 3

[0041](1) Nanometer metakaolin is obtained by calcining nanometer kaolin at 750°C for 5 hours. The obtained metakaolin is immersed in deionized water and dispersed evenly, and the mass ratio of the solution to nano-metakaolin is 30:1. Then, to 100 ml of the nano-metakaolin dispersion liquid, 30 ml of 0.05 calcium iodate and 30 ml of 0.15 M sodium bicarbonate aqueous solution were successively added, and the reaction was carried out at room temperature for 10 min. The solid product was obtained by filtration and separation, washed three times with deionization, and dried at 100° C. to obtain nano-metakaolin calcium hydroxide composite powder.

[0042] (2) Disperse in isopropanol with a mass ratio of 10wt% to prepare a repairing protection solution. Under the conditions of 25°C and 45% humidity, the sandstone stones were treated 3 times by the spray coating method and maintained for 28 days.

[0043] (3) After treatment, the penetration depth is 9.8mm, the degree of solidifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com