Polymer ratio fluorescence sensor with sulfur dioxide recognition function as well as preparation method and application of polymer ratio fluorescence sensor

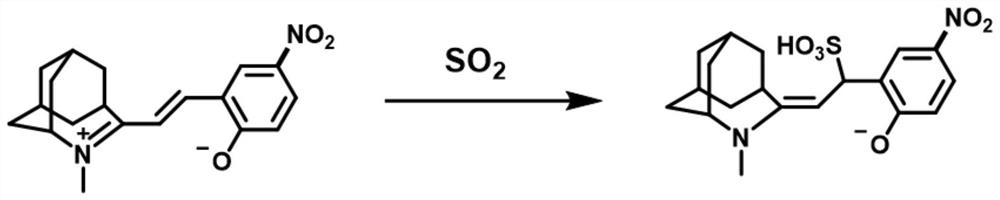

A sulfur dioxide, ratio fluorescence technology, applied in chemical instruments and methods, fluorescence/phosphorescence, instruments, etc., can solve the problems of photobleaching damage of spiropyran molecules, increase biological toxicity, object damage, etc., and achieve convenient and cost-effective post-processing. The effect of low investment and simple synthesis route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Preparation of a polymer ratio fluorescence sensor with sulfur dioxide recognition function, the specific steps are as follows:

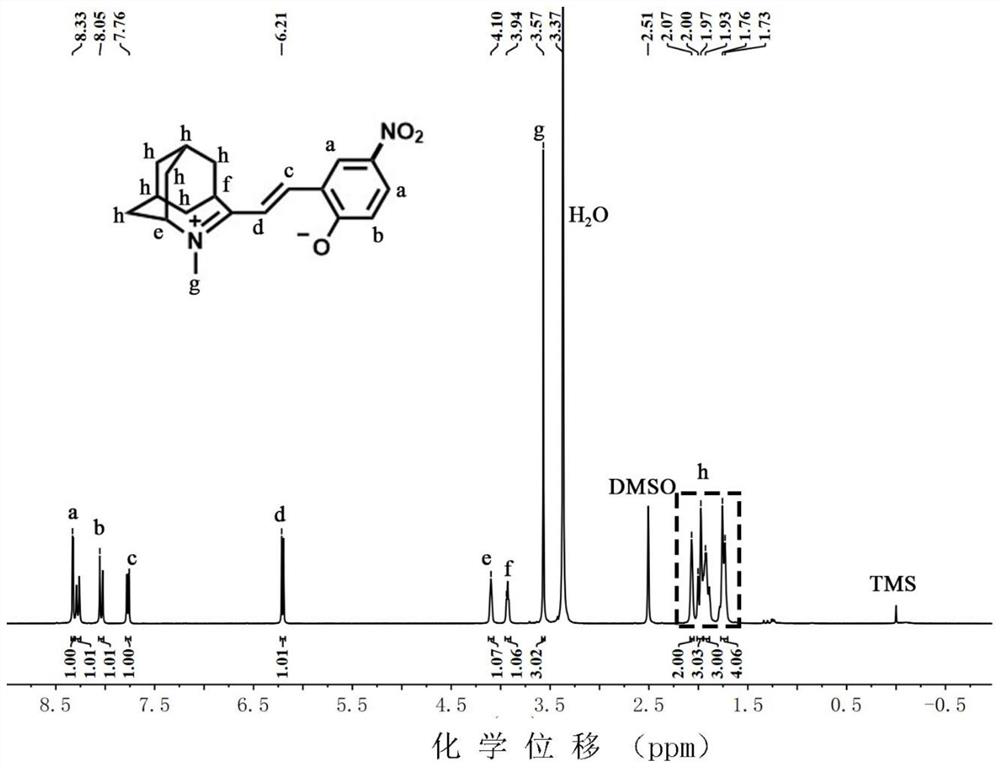

[0036] (1) Dissolve 4,5-dimethyl-4-azaadamantane iodonium salt (1 mmol) and 5-nitrosalicylaldehyde (1.2 mmol) prepared according to the prior art in 20 mL of absolute ethanol, add Piperidine (1.19 mmol) on N 2 Under the conditions of protection and dark, reflux for 12h, after the reaction, 85-95% of the solvent is removed by rotary evaporation, the product is purified by column separation, and dried in vacuum to obtain the target molecule.

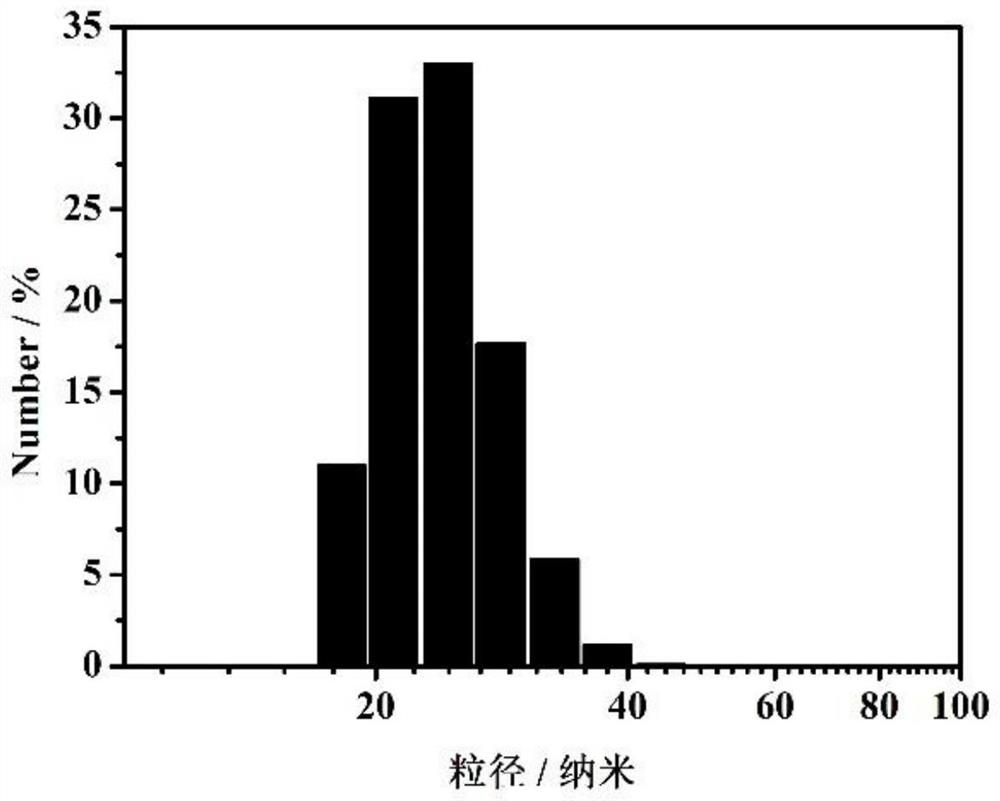

[0037] (2) Take the target molecule synthesized in step (1) and prepare it into 1 mg / mL tetrahydrofuran (THF) solution A, take poly[9,9-dihexylfluorenyl-2,7-diyl] prepared according to the prior art Be prepared into the tetrahydrofuran (THF) solution B of 1 μg / mL, get the polyethylene oxide-co-polystyrene prepared according to the prior art and prepare the tetrahydrofuran (THF) solution C of 1...

Embodiment 2

[0038] Embodiment 2: the preparation of a polymer ratio fluorescence sensor with sulfur dioxide recognition function, the specific steps are as follows:

[0039] (1) 4,5-dimethyl-4-azaadamantane iodonium salt (0.5mmol) and 5-nitrosalicylaldehyde (0.6mmol) prepared according to the prior art were dissolved in 20mL of absolute ethanol, Piperidine (0.595 mmol) was added and placed under N 2 Under the conditions of protection and dark, reflux for 12h, after the reaction, 85-95% of the solvent is removed by rotary evaporation, the product is purified by column separation, and dried in vacuum to obtain the target molecule.

[0040] (2) Take the target molecule synthesized in step (1) and prepare it into 0.5 mg / mL tetrahydrofuran (THF) solution A, take poly[9,9-dihexylfluorenyl-2,7-diyl prepared according to the prior art ] be mixed with the tetrahydrofuran (THF) solution B of 0.5 μg / mL, get the polyethylene oxide-co-polystyrene prepared according to the prior art and be mixed with ...

Embodiment 3

[0041] Embodiment 3: the preparation of a polymer ratio fluorescence sensor with sulfur dioxide recognition function, the specific steps are as follows:

[0042] (1) 4,5-dimethyl-4-azaadamantane iodonium salt (1.5mmol) and 5-nitrosalicylaldehyde (1.8mmol) prepared according to the prior art were dissolved in 20mL of absolute ethanol, Piperidine (1.785 mmol) was added and placed under N 2 Under the conditions of protection and dark, reflux for 12h, after the reaction, 85-95% of the solvent is removed by rotary evaporation, the product is purified by column separation, and dried in vacuum to obtain the target molecule.

[0043] (2) Take the target molecule synthesized in step (1) and prepare it into 1.5 mg / mL tetrahydrofuran (THF) solution A, take poly[9,9-dihexylfluorenyl-2,7-diyl prepared according to the prior art ] Be mixed with the tetrahydrofuran (THF) solution B of 1.5 μg / mL, get the polyethylene oxide-co-polystyrene prepared according to the prior art and be mixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com