RPETG heat shrinkage label film and preparation method thereof

A technology of heat shrinking and shrinking film, applied in the field of RPETG heat shrinkable label film and its preparation, to achieve the effect of recycling waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

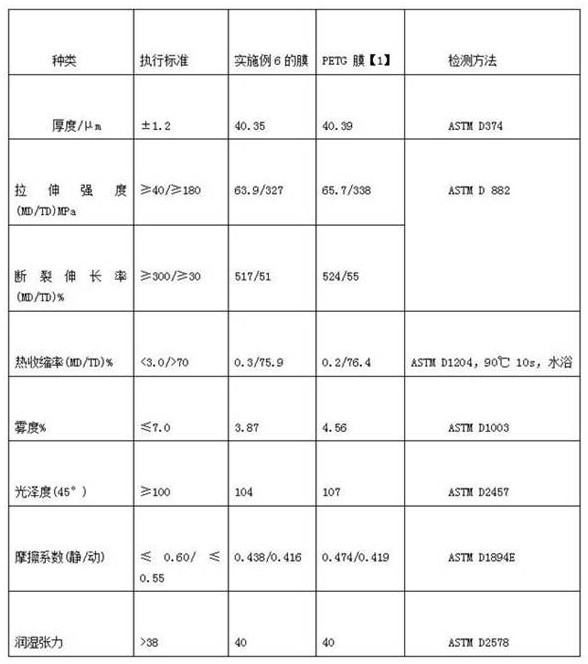

Examples

Embodiment 1

[0034] Embodiment 1: a kind of RPETG heat shrinkable label film, it is characterized in that, comprises main material and auxiliary material, main material comprises the raw material of following mass fractions, 55 parts of PET recycled bottle flakes, 10 parts of PETG shrink film scraps, 25 parts of powder coatings Saturated polyester resin is used; auxiliary materials include transesterification catalyst, polycondensation catalyst, phase transfer catalyst, and catalytic accelerator. The amount of transesterification catalyst is 3ppm of the main material, the amount of polycondensation catalyst is 6ppm of the main material, and the amount of phase transfer catalyst is mainly 3ppm of the feed, and the amount of the catalyst promoter is 2ppm of the main feed. Transesterification catalyst is zinc acetate; polycondensation catalyst is titanium-based catalyst tetrabutyl titanate; phase transfer catalyst is benzyl triethylamine chloride (TEBA); catalytic promoter is organic guanidine...

Embodiment 2

[0035]Embodiment 2: a kind of RPETG heat shrinkable label film, it is characterized in that, comprises main material and auxiliary material, main material comprises the following raw materials by mass, 55 parts of PET recycled bottle flakes, 10 parts of PETG shrink film scraps, 25 parts of powder coating Saturated polyester resin is used; auxiliary materials include transesterification catalyst, polycondensation catalyst, phase transfer catalyst, catalytic accelerator, toner and stabilizer, the amount of transesterification catalyst is 3ppm of the main material, and the amount of polycondensation catalyst is 6ppm of the main material, The amount of the phase transfer catalyst is 3 ppm of the main material, the amount of the catalytic accelerator is 2 ppm of the main material; the amount of the toner is 5 ppm of the main material, and the amount of the stabilizer is 45 ppm of the main material. The transesterification catalyst is manganese acetate; the polycondensation catalyst ...

Embodiment 3

[0036] Embodiment 3: a kind of RPETG heat-shrinkable label film, it is characterized in that, comprises main material and auxiliary material, main material comprises the following raw materials in parts by mass, 58 parts of PET recycled bottle flakes, 12 parts of PETG shrink film scraps, 28 parts of powder coatings Saturated polyester resin; auxiliary materials include transesterification catalyst, polycondensation catalyst, phase transfer catalyst, catalytic accelerator, toner and stabilizer, the amount of transesterification catalyst is 4ppm of the main material, and the amount of polycondensation catalyst is 7ppm of the main material, The amount of the phase transfer catalyst is 4 ppm of the main material, the amount of the catalyst accelerator is 2.5 ppm of the main material; the amount of the toner is 7 ppm of the main material, and the amount of the stabilizer is 52 ppm of the main material. The transesterification catalyst is zinc acetate; the polycondensation catalyst i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com