Al-Si series aluminum alloy ingot and preparation method thereof

A technology for aluminum alloy ingots and aluminum alloys, applied in the field of iron and steel smelting, can solve the problems of low mechanical properties of aluminum alloys, multi-material bauxite, unfavorable environmental protection, etc. The effect of nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

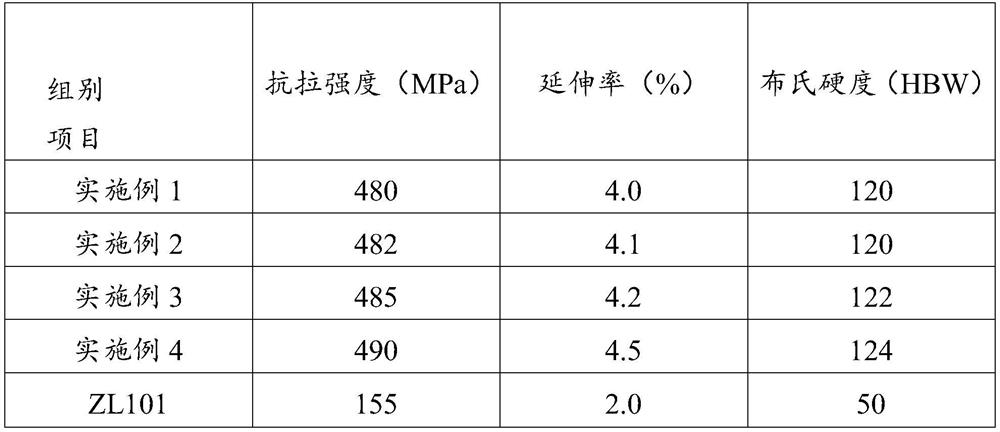

Examples

Embodiment 1

[0022] The Al-Si series aluminum alloy ingot is composed of silicon, copper, manganese, magnesium, titanium, strontium, zirconium and aluminum, and the components are: silicon 8.0%, copper 1.3%, manganese 0.10%, magnesium 0.4%, titanium 0.10%, strontium 0.02%, zirconium 0.35%, and the balance is aluminum.

[0023] A preparation method of an Al-Si series aluminum alloy ingot, comprising the following steps:

[0024] 1) The waste aluminum is subjected to pretreatment: classification, slicing, magnetic separation, cleaning and drying, and is used as a raw material for standby;

[0025] 2) heating the obtained waste aluminum raw material in step 1) to a molten state in a double-chamber reverberatory furnace, then transferring to an electrolytic cell for electrolysis to obtain elemental aluminum liquid, and then injecting elemental aluminum liquid into the aluminum alloy melting furnace;

[0026] 3) Add silicon, copper, manganese, magnesium, titanium, strontium and zirconium into ...

Embodiment 2

[0033] The Al-Si series aluminum alloy ingot is composed of silicon, copper, manganese, magnesium, titanium, strontium, zirconium and aluminum, and the components are: silicon 9.0%, copper 1.6%, manganese 0.23%, magnesium 0.5%, titanium 0.23%, strontium 0.04%, zirconium 0.42%, and the balance is aluminum.

[0034] A preparation method of an Al-Si series aluminum alloy ingot, comprising the following steps:

[0035] 1) The waste aluminum is subjected to pretreatment: classification, slicing, magnetic separation, cleaning and drying, and is used as a raw material for standby;

[0036] 2) heating the obtained waste aluminum raw material in step 1) to a molten state in a double-chamber reverberatory furnace, then transferring to an electrolytic cell for electrolysis to obtain elemental aluminum liquid, and then injecting elemental aluminum liquid into the aluminum alloy melting furnace;

[0037] 3) Add silicon, copper, manganese, magnesium, titanium, strontium and zirconium into ...

Embodiment 3

[0044] The Al-Si series aluminum alloy ingot is composed of silicon, copper, manganese, magnesium, titanium, strontium, zirconium and aluminum, and the components are: silicon 10.0%, copper 1.8%, manganese 0.35%, magnesium 0.6%, titanium 0.35%, strontium 0.05%, zirconium 0.46%, and the balance is aluminum.

[0045] A preparation method of an Al-Si series aluminum alloy ingot, comprising the following steps:

[0046] 1) The waste aluminum is subjected to pretreatment: classification, slicing, magnetic separation, cleaning and drying, and is used as a raw material for standby;

[0047] 2) heating the obtained waste aluminum raw material in step 1) to a molten state in a double-chamber reverberatory furnace, then transferring to an electrolytic cell for electrolysis to obtain elemental aluminum liquid, and then injecting elemental aluminum liquid into the aluminum alloy melting furnace;

[0048] 3) Add silicon, copper, manganese, magnesium, titanium, strontium and zirconium into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com