Preparation method of self-supporting composite nanofiltration membrane

A composite nanofiltration membrane, self-supporting technology, applied in the field of nanofiltration membranes, can solve the problems of stability limiting the development of two-dimensional graphene-based membranes, increasing the length of molecular transport paths, affecting membrane permeability, etc., and achieving good long-term operation and stability. performance and strong alkali resistance, good application value, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a self-supporting composite nanofiltration membrane, comprising the following steps:

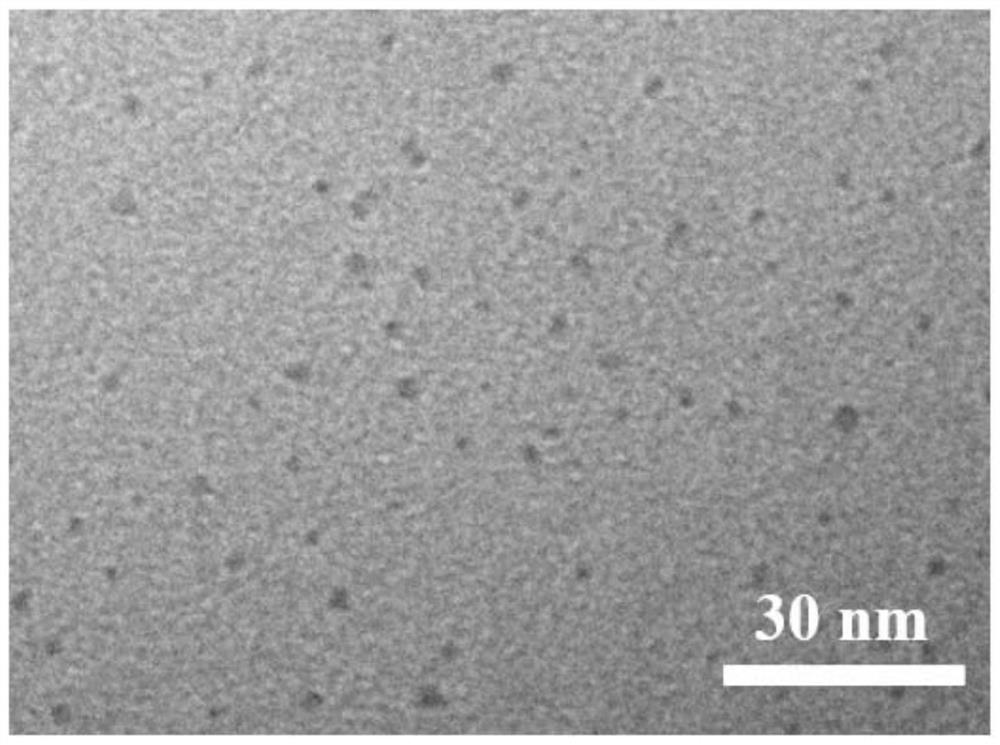

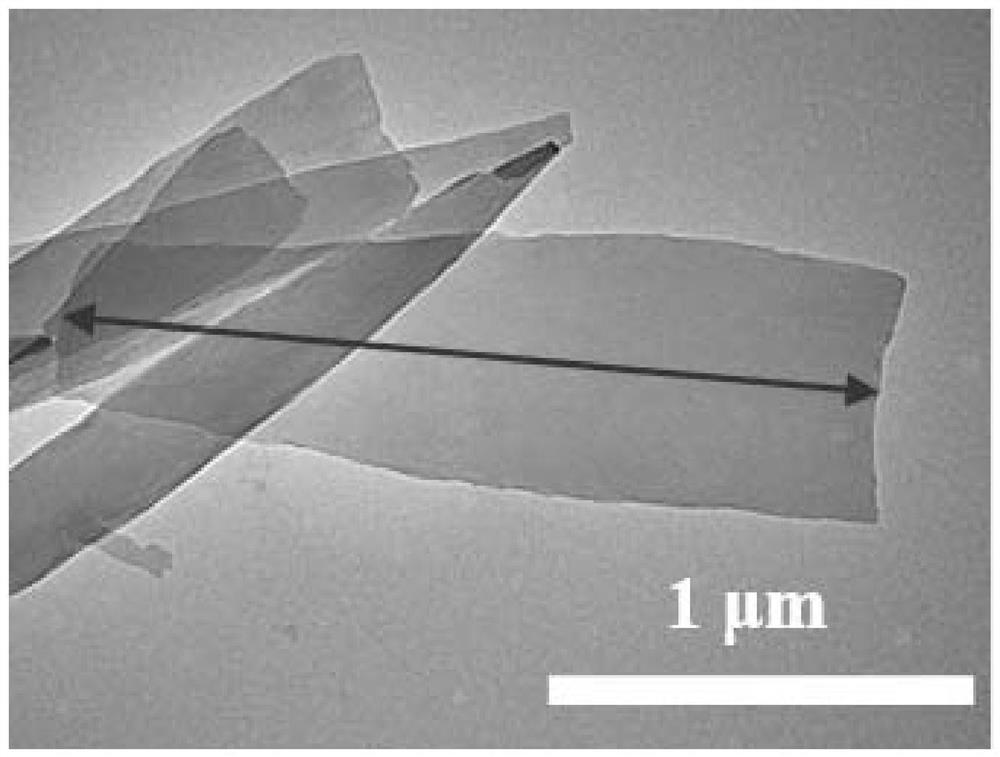

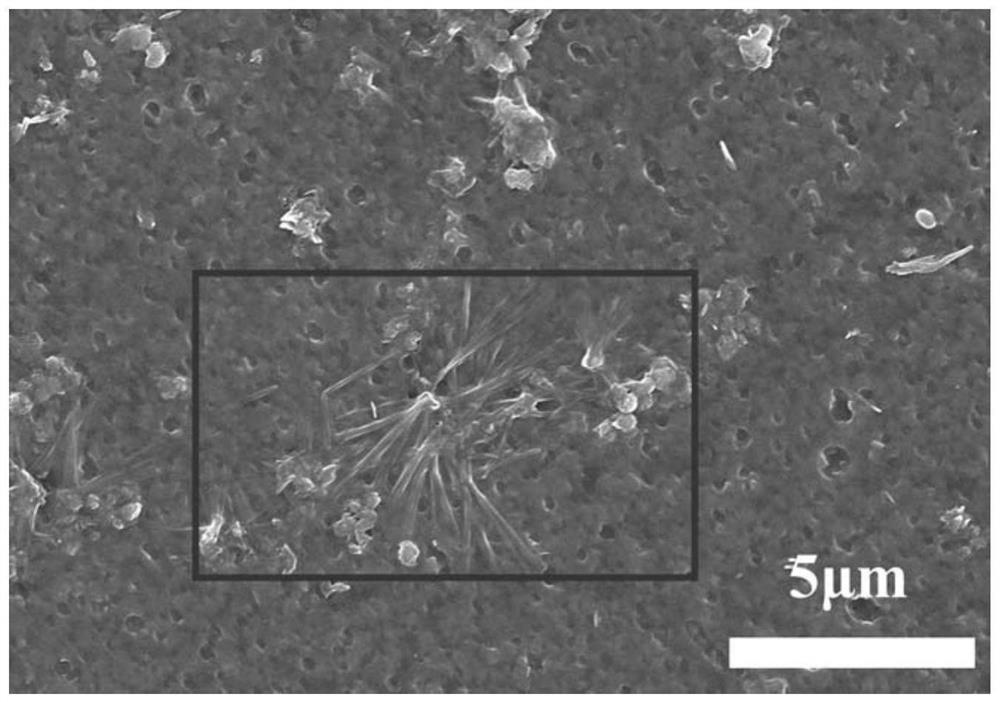

[0030] (1) preparation of aminated graphene quantum dots: 45mg graphene oxide was dispersed in 45mL distilled water through ultrasonic vibration, 15mL ammonia water was added and mixed, and then transferred to the reactor, the reactor was sealed and placed in the muffle furnace, in 120 ℃ constant temperature reaction 5h. After cooling, it was filtered with a sand core filter equipped with a polyethersulfone membrane (pore size: 0.22 μm), and then the filtrate was distilled under reduced pressure in a water bath at 80 °C for 1 h, and then freeze-dried to obtain aminated graphene quantum dot powder. After redissolving, it was filtered with a polyethersulfone filter membrane (pore size 0.1 μm) for a second time, and then freeze-dried again to obtain a pale yellow aminated graphene quantum dot powder. The transmission electron microscope image is as follows. figur...

Embodiment 2

[0035] A preparation method of a self-supporting composite nanofiltration membrane, comprising the following steps:

[0036] (1) step (1) with embodiment 1;

[0037] (2) except that the interfacial polymerization reaction time is 10s, all other steps and conditions are the same as the step (2) of embodiment 1;

[0038] (3) Preparation of composite nanofiltration membrane: Immediately after step (2), 1.5 mL of a 0.02w / v% piperazine aqueous solution with a concentration of 0.02w / v% was injected into the solution after the interfacial polymerization reaction in step (2) at a constant speed, and the reaction was continued for 60s to prepare The porous graphene / polyamide separation layer was obtained, and after removing the aqueous phase solution and the organic phase solution, the porous graphene / polyamide separation layer was loaded on the polyethersulfone filter membrane substrate, and the obtained composite membrane was heat-treated at 45 °C for 10 min to prepare. Obtained fro...

Embodiment 3

[0041] A preparation method of a self-supporting composite nanofiltration membrane, comprising the following steps:

[0042] (1) step (1) with embodiment 1;

[0043] (2) except that the interfacial polymerization reaction time is 30s, all other steps and conditions are the same as the step (2) of embodiment 1;

[0044] (3) with step (3) of embodiment 2.

[0045] The prepared self-supporting composite nanofiltration membrane was 0.1 g L -1 Congo red and methyl orange solution system and 1g L -1 Na 2 SO 4 The solution system was tested under 0.2MPa pressure, and its permeation flux was 13.8L m -2 ·h -1 ·bar -1 , the rejection rate of Congo red is 99.5%, the rejection rate of methyl orange is 38.6%, SO 4 2- The rejection rate of ions is 30.2%, Congo red / SO 4 2- The separation factor is 92.13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com