M (AlTiNbN/AlTiON) + AlTiCON multilayer composite coating for cutting and preparation method of m (AlTiNbN/AlTiON) + AlTiCON multilayer composite coating

A multi-layer composite, al1-a-btianbbn technology, applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve the incompatibility of wear resistance and toughness, insufficient high temperature stability, etc. problem, to achieve the effect of good competence and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing the above-mentioned m(AlTiNbN / AlTiON)+AlTiCON multi-layer composite coating for cutting, comprising the following steps:

[0031] Use powder metallurgy to prepare cemented carbide or cermet tool substrate, and carry out deep processing (grinding, sandblasting, polishing) on the tool substrate to obtain the deep processing tool substrate;

[0032] Pretreatment (including cleaning and drying, argon ion bombardment etching and activation treatment) to the deep-processed tool substrate to obtain the pretreated tool substrate;

[0033] Alternate deposition of Al on the pretreated tool substrate by cathodic arc ion plating in physical vapor deposition 1-a-b Ti a Nb b N coating and Al 1-c-d Ti c O d N coating, then keep the total working pressure constant, gradually reduce the gas flow ratio and continue to deposit Al 1-x-y Ti x C y O z~0 N 1-z~1 coating.

[0034] Preferably, the substrate bias of the anio...

Embodiment 1

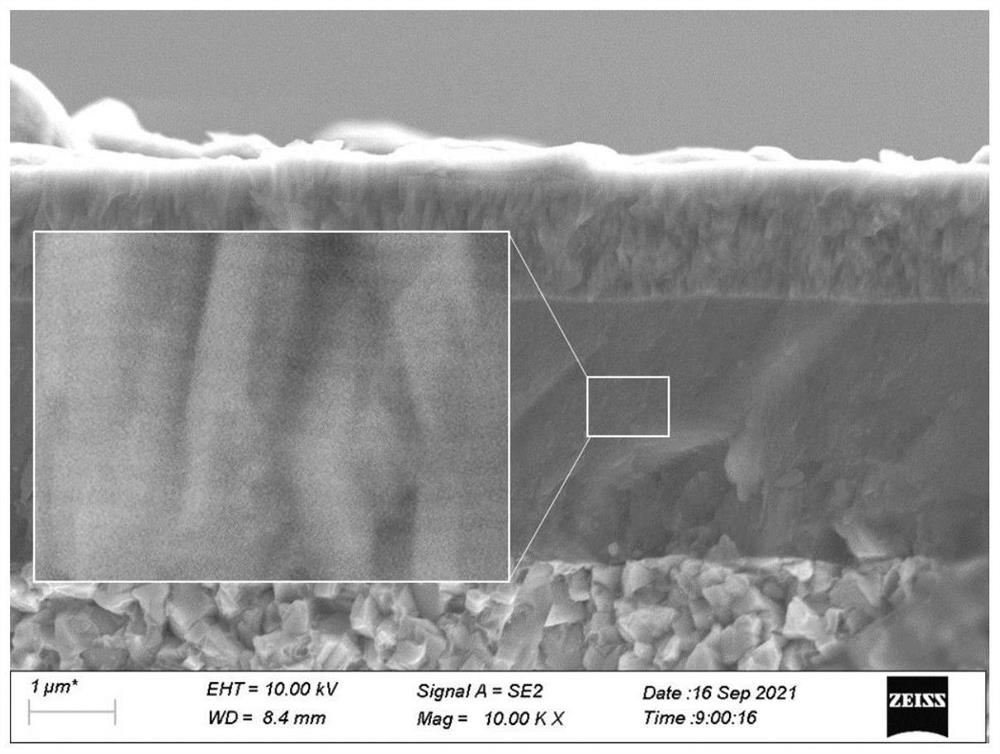

[0036] such as figure 1 The shown multi-layer composite structure coating tool of the present invention is composed of tool substrate, 100 (AlTiNbN / AlTiON), and AlTiCON coatings from inside to outside, and the total thickness of the coating is 3.28 μm;

[0037] Among them, the thickness of 100 (AlTiNbN / AlTiON) coating is 2.12 μm, and the thickness of AlTiCON coating is 1.16 μm;

[0038] The 100 (AlTiNbN / AlTiON) composite coating includes AlTiNbN layers and AlTiON layers alternately deposited periodically from the inside to the outside, including 100 periods, the thickness of the AlTiNbN single layer is 0.012μm, and the thickness of the AlTiON single layer is 0.01μm;

[0039] The AlTiCON coating is an AlTiCON layer with a single-layer gradient structure with a reduced O / N stoichiometric ratio.

[0040] The AlTiNbN layer in the above-mentioned multilayer composite structure coating is composed of Al in atomic ratio. 0.6 Ti 0.35 Nb 0.05 N, AlTiON layer is composed of Al in at...

Embodiment 2

[0050] A multi-layer composite structure coating tool of the present invention as in Example 1, which is composed of a tool matrix, 50 (AlTiNbN / AlTiON), and AlTiCON coatings from the inside to the outside, and the total thickness of the coating is 3.16 μm;

[0051] Among them, the thickness of 50 (AlTiNbN / AlTiON) coating is 2.08 μm, and the thickness of AlTiCON coating is 1.08 μm;

[0052]The 50 (AlTiNbN / AlTiON) composite coating includes AlTiNbN layers and AlTiON layers alternately deposited periodically from the inside to the outside, including 50 periods, the thickness of the AlTiNbN single layer is 0.021μm, and the thickness of the AlTiON single layer is 0.019μm;

[0053] The AlTiCON coating is an AlTiCON layer with a single-layer gradient structure with a reduced O / N stoichiometric ratio.

[0054] The AlTiNbN layer in the above-mentioned multilayer composite structure coating is composed of Al in atomic ratio. 0.6 Ti 0.35 Nb 0.05 N, AlTiON layer is composed of Al in at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com