Surface treatment method for reducing secondary electron yield of oxygen-free copper

A surface treatment and secondary electron technology, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems of low bonding strength and poor bonding stability, and achieve the effects of low cost, effective deposition, and low secondary electron output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

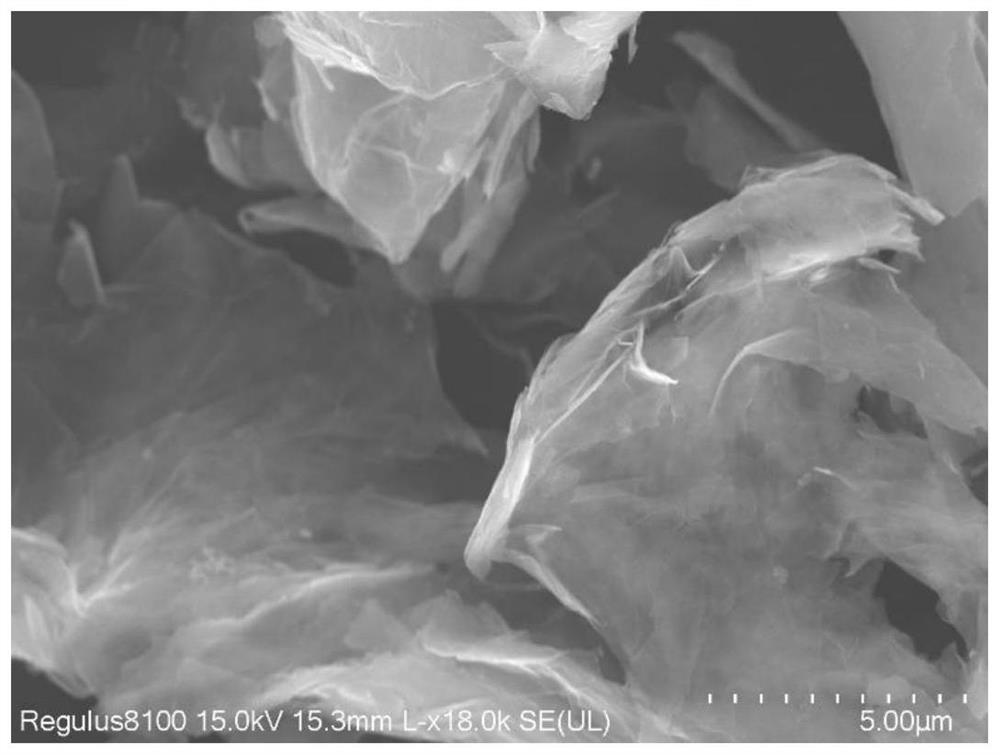

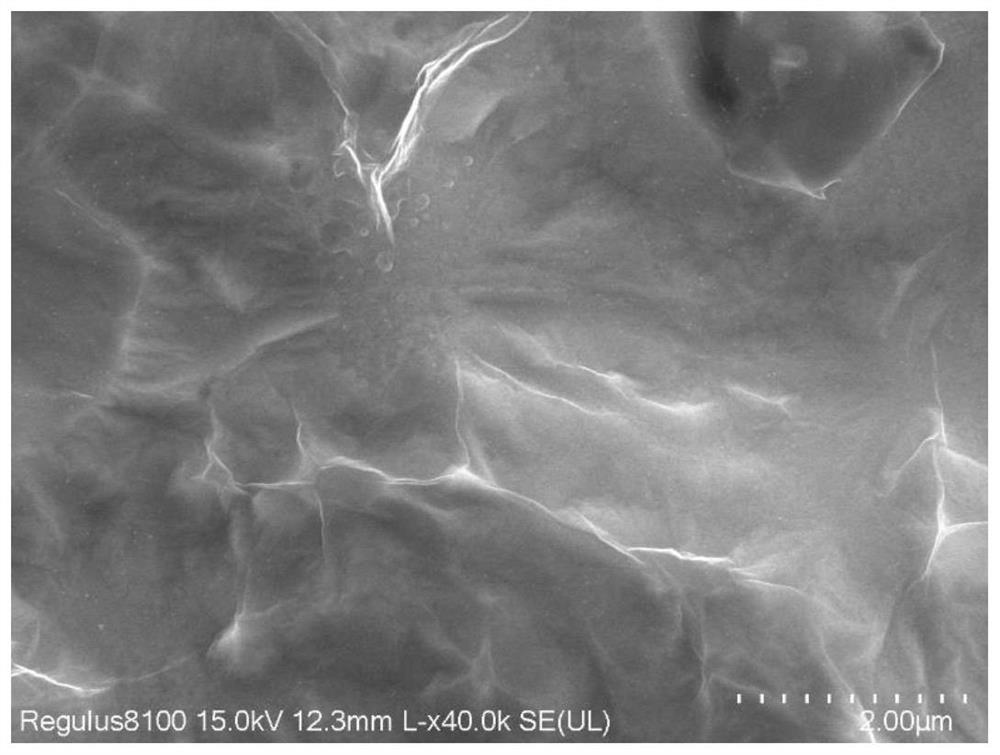

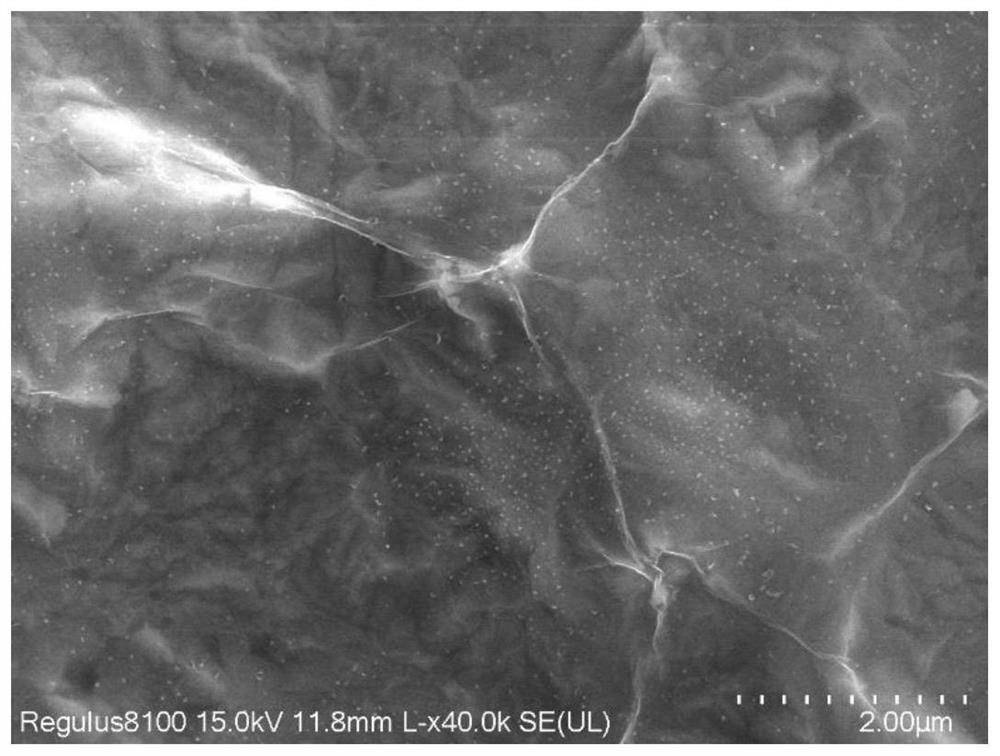

[0060] Weigh 0.06g of graphene oxide, place it in 150ml of deionized water, and ultrasonically stir for 30min with a 1200W ultrasonic disperser until graphene oxide is completely dispersed in deionized water to form a stable graphene oxide plating solution; Weigh 8mmol of pentahydrate sulfuric acid Copper, dissolved in 150 ml of deionized water and stirred until completely dissolved. The oxygen-free copper sheet is used as the anode and the pure copper sheet is used as the cathode. The two electrodes are first placed in the graphene oxide plating solution at the same time, and the distance between the two electrodes is adjusted to 3 cm. A DC voltage was applied to deposit graphene oxide with a deposition voltage of 5V and a deposition time of 30s. Then the power was turned off, the two electrodes were taken out, and placed in a copper sulfate plating solution. The oxygen-free copper on which graphene oxide was deposited was used as the cathode, and the pure copper sheet was us...

Embodiment 2

[0063] Weigh 0.08g of graphene oxide, place it in 150ml of deionized water, and ultrasonically stir it for 10min with a 1200W ultrasonic disperser until graphene oxide is completely dispersed in deionized water to form a stable graphene oxide plating solution; Weigh 10mmol of pentahydrate sulfuric acid Copper, dissolved in 150 ml of deionized water and stirred until completely dissolved. The oxygen-free copper sheet is used as the anode and the pure copper sheet is used as the cathode. The two electrodes are first placed in the graphene oxide plating solution at the same time, and the distance between the two electrodes is adjusted to 3 cm. A DC voltage was applied to deposit graphene oxide with a deposition voltage of 5V and a deposition time of 30s. Then the power was turned off, the two electrodes were taken out, and placed in a copper sulfate plating solution. The oxygen-free copper on which graphene oxide was deposited was used as the cathode, and the pure copper sheet wa...

example 3

[0066] Weigh 0.1g of graphene oxide, place it in 150ml of deionized water, and ultrasonically stir for 30min with a 1200W ultrasonic disperser until graphene oxide is completely dispersed in deionized water to form a stable graphene oxide plating solution; Weigh 8mmol of pentahydrate sulfuric acid Copper, dissolved in 150 ml of deionized water and stirred until completely dissolved. The oxygen-free copper sheet is used as the anode and the pure copper sheet is used as the cathode. The two electrodes are first placed in the graphene oxide plating solution at the same time, and the distance between the two electrodes is adjusted to 3 cm. A DC voltage was applied to deposit graphene oxide with a deposition voltage of 3 V and a deposition time of 30 s. Then the power was turned off, the two electrodes were taken out, and placed in a copper sulfate plating solution. The oxygen-free copper on which graphene oxide was deposited was used as the cathode, and the pure copper sheet was u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com