Light-emitting device and preparation method thereof

A light-emitting device, quantum dot light-emitting technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of affecting electron injection efficiency, poor interface fusion, easy to form charges, etc., to reduce physical structure defects and surface roughness, good bonding tightness, and the effect of promoting regrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] as attached figure 1 As shown, the first aspect of the embodiments of the present application provides a method for preparing a light-emitting device, including the following steps:

[0024] S00. A laminated composite structure of a quantum dot light-emitting layer and an electron transport layer is prepared between the anode and the cathode;

[0025] Wherein, the electron transport layer includes a metal oxide transport material; the laminated composite structure is treated by ultraviolet light irradiation.

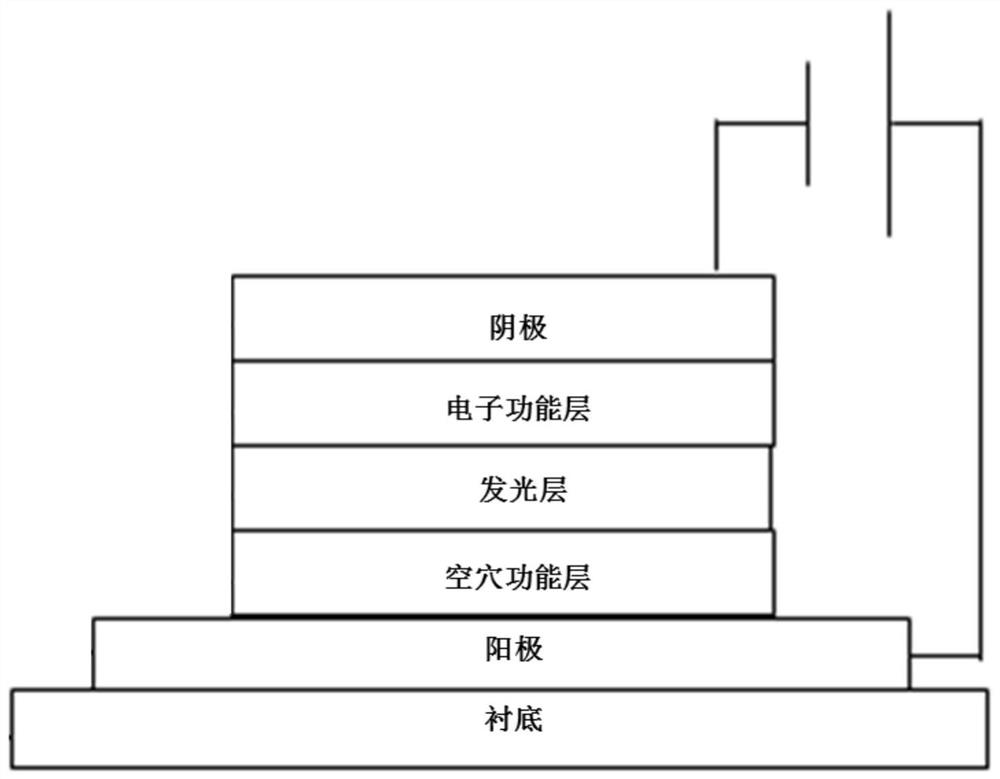

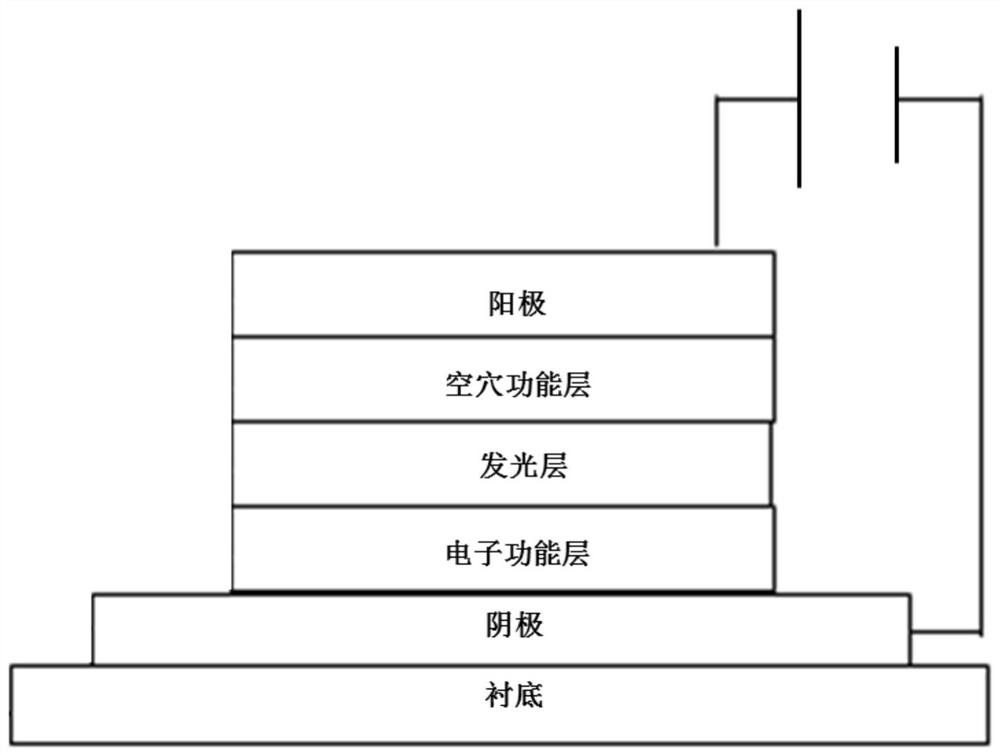

[0026] In the method for preparing a light-emitting device provided in the first aspect of the present application, a laminated composite structure of a quantum dot light-emitting layer (QD) and an electron transport layer (ETL) is prepared between an anode and a cathode, and the laminated composite structure is irradiated with ultraviolet light ( UV) treatment, through ultraviolet light irradiation treatment, the electrons of O in the metal oxide transport mater...

Embodiment 1

[0072] A light-emitting diode, comprising the following preparation steps:

[0073] (1) Provide ITO anode, and pre-treat the anode: use alkaline washing solution (preferably PH>10 ultrasonic for 15 min, deionized water ultrasonic for 15 min twice, isopropanol ultrasonic cleaning for 15 min, dry at 80 ℃ for 2 h, ozone ultraviolet Process for 15min.

[0074] (2) forming a hole injection layer on the anode of step (1): under an electric field, spin-coating the PEDOT:PSS solution on the anode, spin-coating at 5000 rpm for 40 s, and then annealing at 150° C. for 15 min to form a hole-injecting layer; wherein , the action direction of the electric field is perpendicular to the anode and towards the hole injection layer, and the electric field strength is 10 4 V / cm.

[0075] (3) Forming a hole transport layer on the hole injection layer: under an electric field, spin-coat TFB solution (concentration of 8 mg / mL, solvent is chlorobenzene) on the hole injection layer, spin at 3000 rpm...

Embodiment 2

[0081] A light-emitting diode, comprising the following preparation steps:

[0082](1) Prepare the quantum dot light-emitting layer on the substrate: take the CdSe / ZnS quantum dot solution (concentration is 30mg / mL, the solvent is n-octane), put the CdSe / ZnS quantum dot solution in a glove box (water oxygen content is less than 0.1ppm) ) was spin-coated on the substrate at a speed of 3000 rpm to form a light-emitting layer.

[0083] (2) Preparation of electron transport layer in the light-emitting layer: in the glove box (water oxygen content is less than 0.1ppm), spin-coat ZnO solution (concentration is 45mg / mL, solvent is ethanol) on the light-emitting layer, spin-coating at 3000rpm for 30s Annealed at 80°C for 30min to form an electron transport layer.

[0084] (3) in H 2 The O content is less than 1ppm, the temperature is 80℃, the UV wavelength is 320nm, and the intensity is 300mJ / cm 2 UV light was applied to the laminated composite structure of the quantum dot light-em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com