Method for preparing high-purity calcium carbonate from high-calcium fly ash by using recyclable amino acid extracting agent

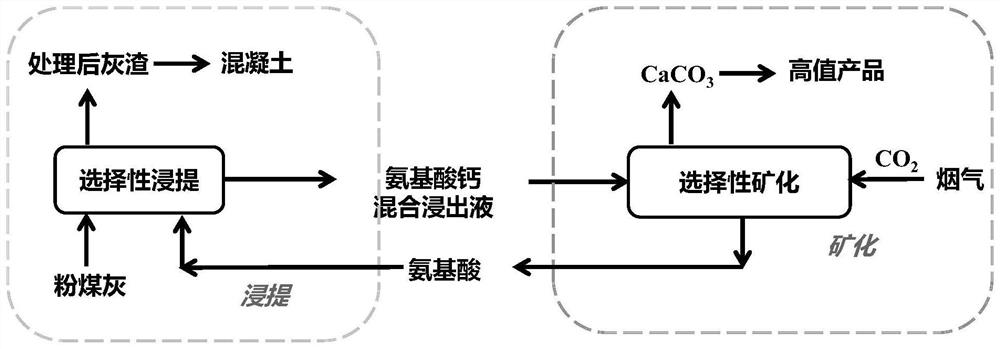

A high-calcium fly ash, amino acid technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of increasing the cost of the indirect method and the rapid decay of the cycle performance, and achieve the improvement of the reaction rate and conversion rate, high efficiency and selectivity. Effects of leaching, strong pH buffering properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

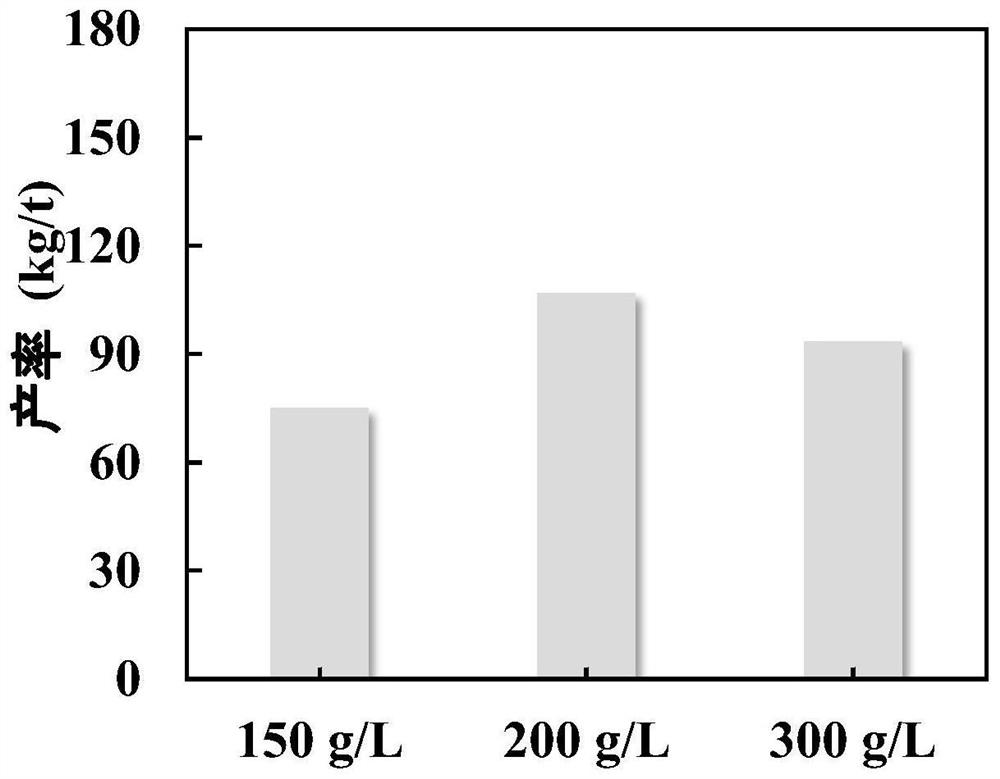

[0025] 1) Add high calcium fly ash with a solid-liquid ratio of 150g / L, 200g / L and 300g / L into 2mol / L glycine to prepare a mixed slurry. The stirring speed is 200rpm, and the extraction process is performed for 1 hour to prepare calcium source leaching. slurry;

[0026] 2) Perform solid-liquid separation on the leaching slurry, take the leaching solution and introduce CO 2 15% CO by volume 2 / N 2 Mixed gas as simulated flue gas for CO 2 mineralization;

[0027] 3) After 1 hour of reaction, stop gas supply, carry out solid-liquid separation on the mineralized slurry, recycle the filtrate as a leaching agent, and dry the solid to obtain a high-purity calcium carbonate product.

[0028] 4) Take 30 parts of standard cement, 20 parts of fly ash slag, 25 parts of quartz sand, and 20 parts of water, and stir to obtain a mixture. Under the conditions of humidity of 95% and temperature of 20° C., and curing for 28 days, fly ash concrete can be obtained.

[0029] like figure 2 S...

Embodiment 2

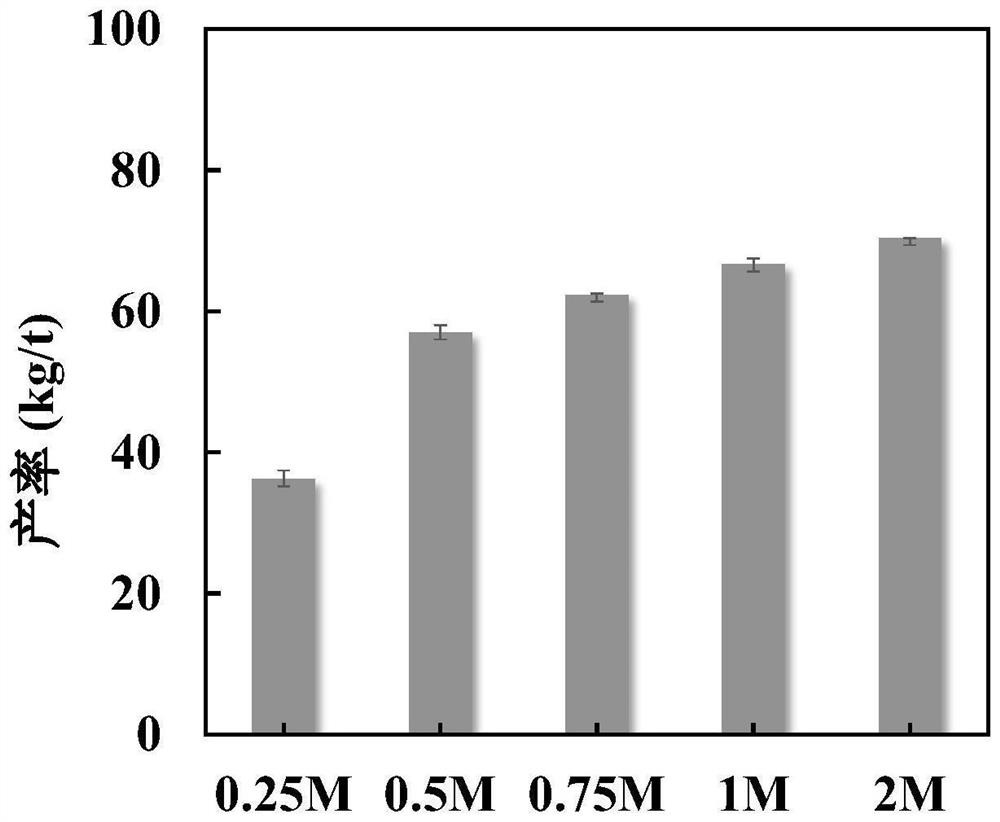

[0031] 0.25mol / L, 0.5mol / L, 1mol / L, 2mol / L glycine solution was used as the leaching agent, the solid-liquid ratio was 200g / L, and other parameters, conditions and implementation steps were consistent with those in Example 1, as shown in Figure 3 Shown is the calcium carbonate yield of 200g / L fly ash in different glycine concentrations, such as Figure 4 Shown is the calcium carbonate morphology of 200 g / L fly ash in 2 mol / L glycine.

[0032] Depend on Figure 2-4 It is known that:

[0033] 1. When the solid-liquid ratio is 150-300g / L, the calcium carbonate yield is all >75kg / t, and when the solid-liquid ratio is 200g / L, the highest yield is 107kg / t.

[0034] 2. As the concentration of glycine increases, the yield of calcium carbonate increases.

[0035] 3. When 200g / L fly ash is added to 2mol / L glycine, the obtained calcium carbonate is a typical spherical vaterite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com