Preparation method and application of novel material CNTs-TiO2 coated CuFe2O4

A new type of material and application method technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of difficult recovery of base photocatalysts, poor reusability, secondary pollution, etc. To achieve long life, avoid secondary pollution, strong oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

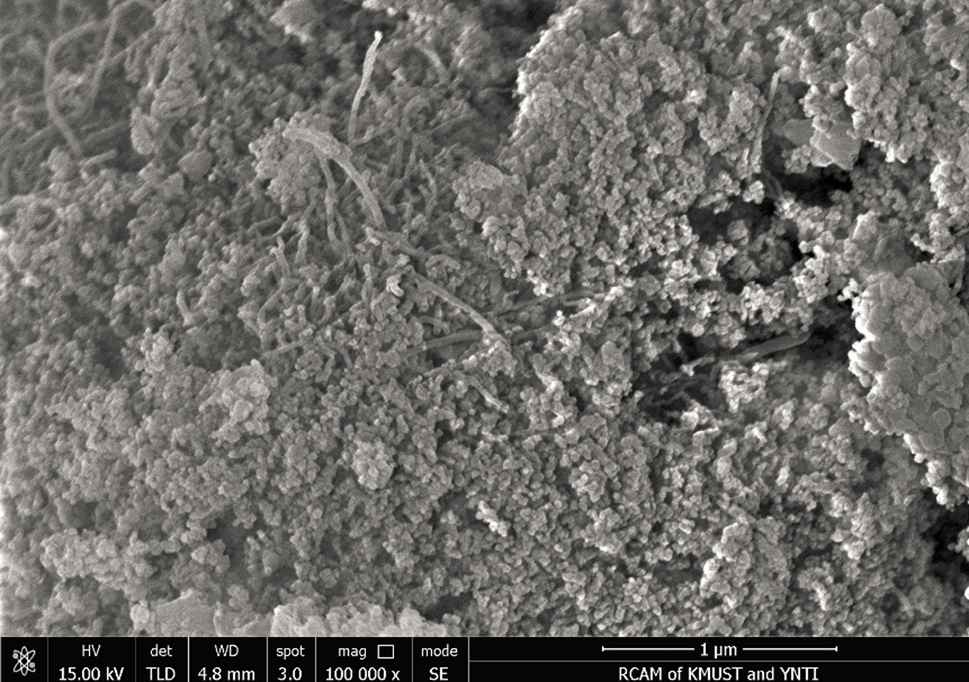

[0053] CNTs-TiO used in this example 2 @CuFe 2 O 4 Nanoparticles were prepared according to the following steps: Cu(NO) 3 ) 2 ·3H 2 O and Fe (NO 3 ) 3 ·9H 2 O was dissolved in a flask containing ultrapure water, and then stirred in a 60 °C water bath for 1 h; citric acid powder was added to the solution, and the mixed solution was further stirred in a 60 °C water bath for 3 h. The obtained transparent sol was transferred to an oven for drying for several hours to obtain a gel; the gel was transferred to a muffle furnace for calcination. The calcined samples were ground and rinsed with ultrapure water for several times until the solution became neutral, and then transferred to an oven to dry for several hours to obtain nano-particles of CuFe. 2 O 4 . Weigh CNTs into 30ml of water, ultrasonically disperse for 10min, and add commercial TiO 2 and sonicated for 30 min. Then add the CuFe prepared above 2 O 4 The nanoparticles were sonicated again for 10 min and then st...

Embodiment 2

[0060] For the CNTs-TiO in Example 1 2 @CuFe 2 O 4 / PMS / light system, we performed free radical quenching experiments. Specifically:

[0061] Weigh 50mg CNTs-TiO 2 @CuFe 2 O 4 The catalyst was added to 100 mL of ciprofloxacin solution (20 mg / L) with 3M ethanol and 3M tert-butanol, respectively, and stirred for 30 min in the dark to make ciprofloxacin reach the equilibrium of adsorption and desorption on the catalyst surface. After adding 1mM PMS, a mercury lamp and a 290nm filter were used, and a light source with a wavelength above 290nm was reserved for irradiation; sampling and analysis were carried out at 0min3min5min7min10min15min20min30min, and the UV-Vis spectrophotometer was used to measure the concentration of ciprofloxacin at a wavelength of 277nm. content. The degradation of ciprofloxacin under different conditions was observed.

[0062] Ethanol can quench SO 4 ·− and ·OH, tert-butanol can remove ·OH from the system, after adding ethanol, such as Figure 5...

Embodiment 3

[0064] For the CNTs-TiO2@CuFe2O4 / PMS / light system in Example 1, we conducted material cycling experiments. Specifically:

[0065] Weigh 50mg CNTs-TiO 2 @CuFe 2 O 4 The catalyst was added to 100 mL of ciprofloxacin solution (20 mg / L), and stirred for 30 min in the dark to make ciprofloxacin reach the equilibrium of adsorption and desorption on the surface of the catalyst. After adding 1mM PMS, a mercury lamp and a 290nm filter were used, and the light source above 290nm was reserved for irradiation; sampling and analysis were carried out at 0min 3min 5min 7min 10min 15min 20min 30min respectively, and the UV-Vis spectrophotometer was used to measure the concentration of ciprofloxacin at a wavelength of 277nm. content. The degradation of ciprofloxacin was observed at different times. After the materials in the solution are separated with a permanent magnet, they are cleaned and desorbed with ethanol and water, and then placed in an oven to dry for use. The material can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com