Method for preparing micro-nano iron powder through hydrogen reduction of ultra-pure iron ore concentrate

An ultra-pure iron concentrate, micro-nano technology, applied in the direction of nano-technology, process efficiency improvement, etc., can solve the problems that cannot meet the particle size requirements, micro-nano iron powder is difficult to achieve mass production, low-cost mass production, etc., to achieve The effect of improving the reduction reaction efficiency, cheap raw materials, and stable sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This example is directed to the production of micro- and nano-scale iron powders.

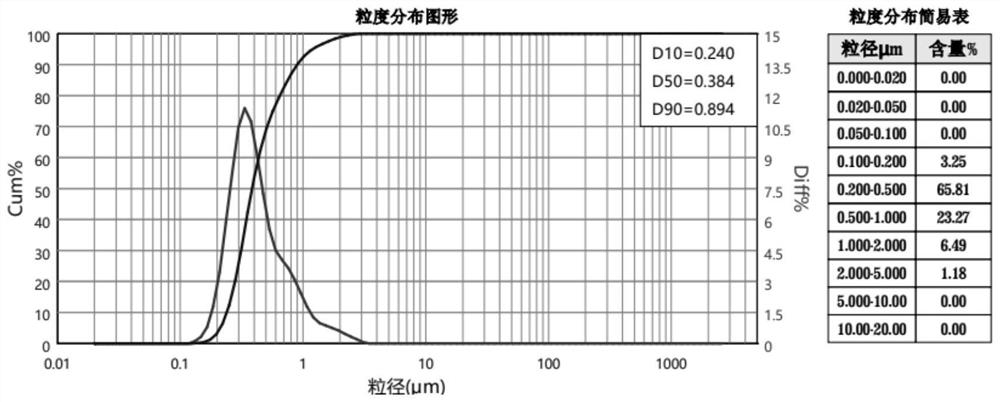

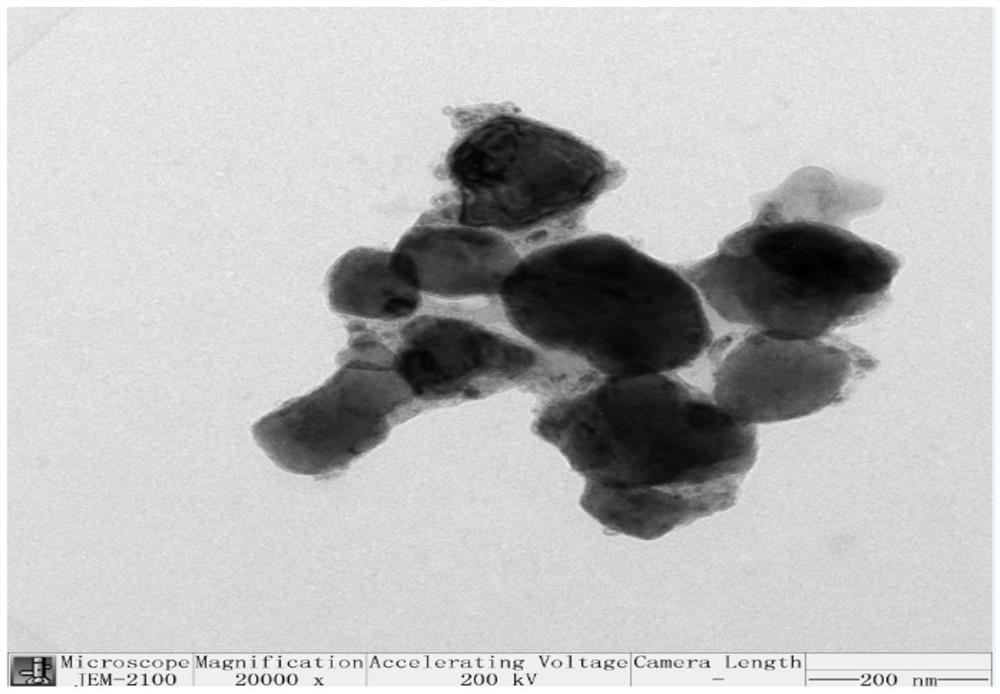

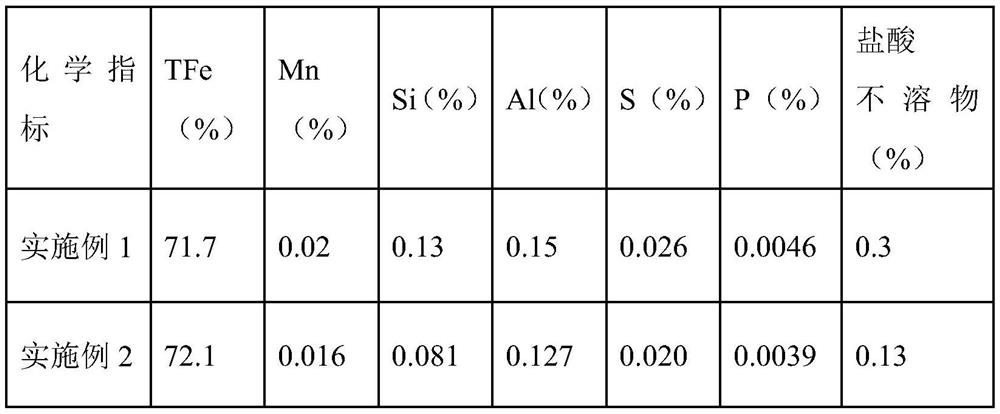

[0035]The ultra-pure iron concentrate was prepared by beneficiation, the iron grade was 71.6%, and the particle size distribution was in the range of 20-80 μm. The ultra-pure iron concentrate was placed in a planetary ball mill, and ceramic grinding beads were added. The ratio of material to ball is 1:1, the rotating speed is set to 270r / min, and the work is 60min, and the micron-level ultra-pure iron ore is obtained by grinding, and the D50 is about 10 microns. After grinding, the material is added to the nano-sand mill, and the main parameters are set as follows: the diameter of the grinding beads is 0.3mm zirconia grinding beads, the material-to-ball ratio is 1:1, the pure water is the grinding medium, the solid-liquid ratio is 1:7, the polyethylene Pyrrolidone (PVP) is a dispersant, the addition amount is 0.7%, and the motor speed is 2400r / min. After grinding for 6 hours, take it ou...

Embodiment 2

[0038] This embodiment has higher requirements for the production of iron powder with regard to particle size and purity.

[0039] The ultra-pure iron ore concentrate is prepared by beneficiation, which is characterized by the more strict and cumbersome beneficiation process, the iron grade is 72.1%, and the particle size distribution is in the range of 20-60 μm, which is suitable for the production of products with higher purity. Place the ultra-pure iron ore concentrate in the stirring mill, add ceramic grinding beads, the diameter of the grinding beads is 2mm, the material-to-ball ratio is 1:1, alcohol is added as the grinding medium, the solid-liquid ratio is 1:3, and the speed is set to 2500r / min , work for 4 minutes, and grind to obtain micron-scale ultra-pure iron ore concentrate with D90 of 17 microns and D50 of 8 microns. After grinding, the material is added to the nano-sand mill, and the main parameters are set as follows: the diameter of the grinding beads is 0.1mm...

Embodiment 3

[0043] Embodiment 3 (comparative example)

[0044] The processing technology of iron concentrate is the same as that in Example 1, and the iron concentrate is ground and dried in two stages to obtain ultra-fine-grained powder.

[0045] The powder is loosely distributed on the steel belt of the steel belt reduction furnace, the material height is 5mm, the temperature of the reduction section is set to 800°C, the speed of the machine is controlled to adjust the reduction time to 3h, and the amount of hydrogen introduced during this time is controlled to be required by the material reduction theory. 5 times the amount of hydrogen. In this production process, due to the increase of the reduction temperature and the extension of the reduction time, the hydrogen utilization rate in the reduction process is high and the product impurity content is lower. The subsequent ultrasonic process is depolymerized, and if the reduced iron is finely ground by mechanical grinding, on the one ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com