Flame-retardant thermoplastic polyurethane and preparation method thereof

A thermoplastic polyurethane and flame-retardant technology, which is applied in the synthesis and processing of polyurethane, can solve the problems of large amount of added flame-retardant fillers, unenvironmental-friendly production methods, and easy precipitation of fillers, etc., to achieve the suppression of smoke release and high mechanical properties. , the effect of reducing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

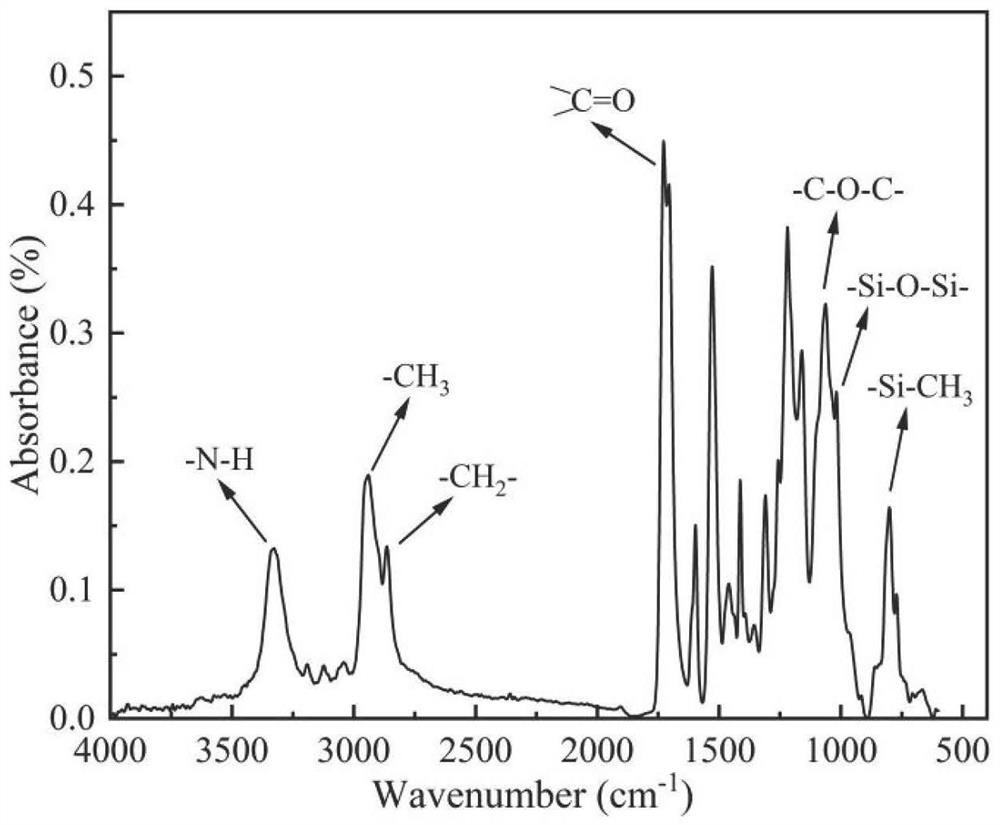

[0032]A preparation method of silicon-based block thermoplastic polyurethane (Si-TPU): before use, hydroxybutyl-terminated polydimethylsiloxane (PDMS) and polycaprolactone diol (PCL) are heated at 120° C. Vacuum dehydration for 2 h, and then use after cooling to room temperature. 126 g of 4,4'-methylene diphenyl diisocyanate (MDI) was added to a three-necked flask equipped with a stirrer and nitrogen device, and it was stirred and melted into a colorless and transparent liquid at 60 °C; then , adding 219.47g of PCL and 54.87g of PDMS to mix evenly; heating up to make PDMS, PCL and MDI react at 80°C for 2h to obtain a polyurethane prepolymer (PUP), the PUP structural formula is as follows: formula I (m and n in formula I) is the degree of polymerization), and its NCO% value was determined to be 5.38±0.27% by the di-n-butylamine method. Take 400.34g of PUP, carry out chain extension according to the chain extension coefficient f=1, add 23.077g of chain extender 1,4-butanediol (...

Embodiment 2

[0035] A preparation method of flame-retardant thermoplastic polyurethane, comprising the following steps:

[0036] (1) the preparation of Si-TPU, the preparation method is the same as Example 1;

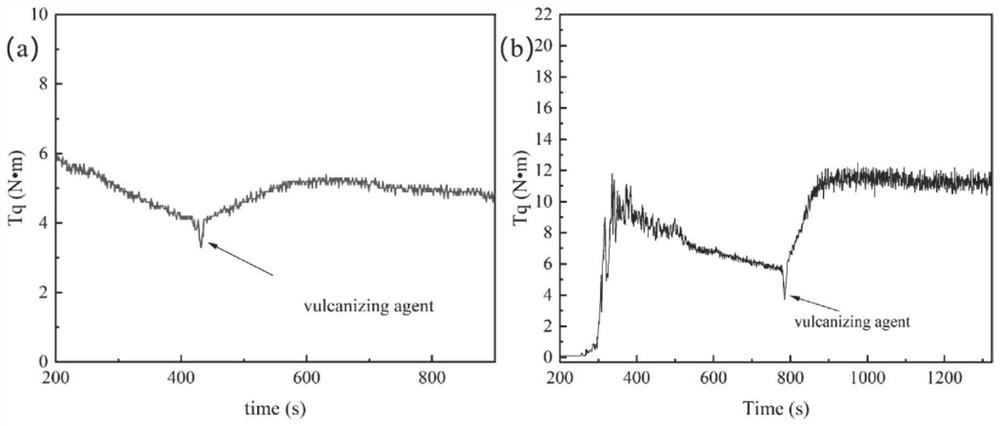

[0037] (2) Preparation of composite methyl vinyl silicone rubber: take 100 g of methyl vinyl silicone rubber (VMQ) raw rubber, 40 g of fumed silica and a structure control agent (containing hydroxyl groups with a mass fraction of 8.5% to 10.0% hydroxyl groups) Silicone oil, OH-PDMS) 4g, added to the RM-200C torque rheometer in turn, mixed uniformly for 15min at 120°C and 60r / min, then the mixed glue was extruded on an open mixer and placed for 4h to obtain a composite methyl vinyl silicone rubber;

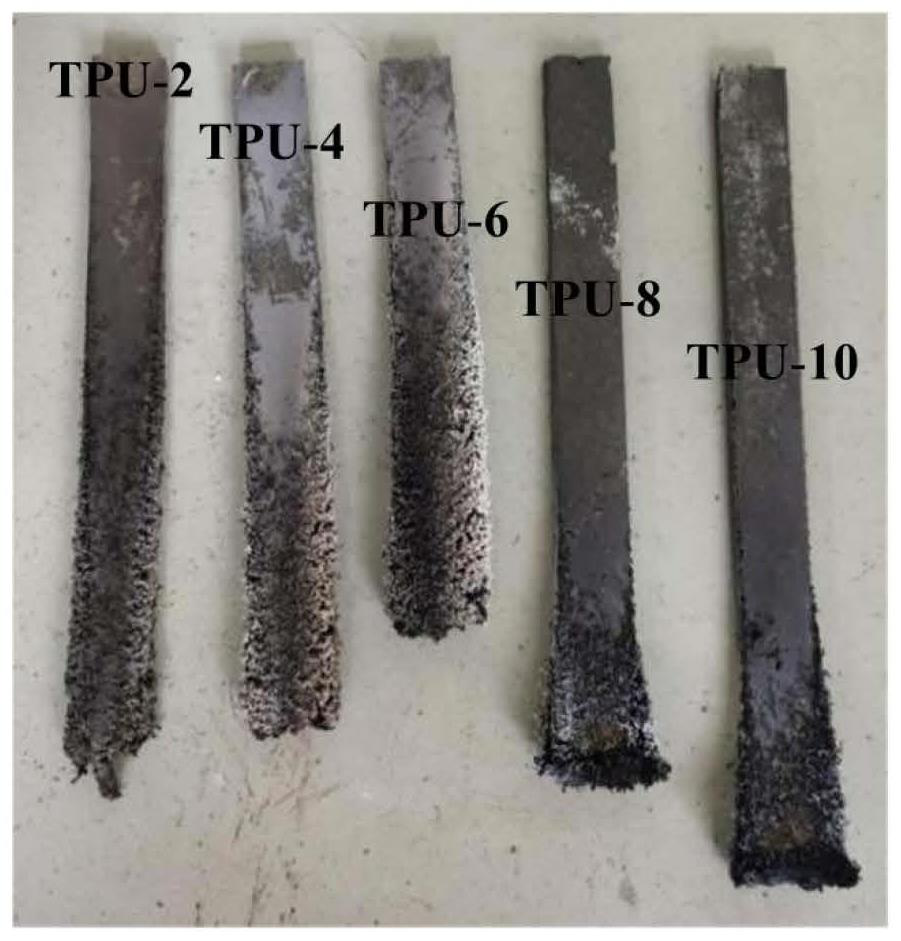

[0038] (3) Preparation of flame-retardant thermoplastic polyurethane: The Si-TPU prepared in step (1) and the composite methyl vinyl silicone rubber prepared in step (2) were first dried at 105° C. for 2 h for use; 37.5 g of Si- TPU and 13.5g of compound methyl vinyl silicone rubber we...

Embodiment 3

[0040] A preparation method of flame-retardant thermoplastic polyurethane, comprising the following steps:

[0041] (1) the preparation of Si-TPU, the preparation method is the same as Example 1;

[0042] (2) the preparation of composite methyl vinyl silicone rubber, the preparation method is the same as that of embodiment 2;

[0043] (3) Preparation of flame-retardant thermoplastic polyurethane: The Si-TPU prepared in step (1) and the composite methyl vinyl silicone rubber prepared in step (2) were first dried at 105° C. for 2 hours for later use; 35.2 g of Si- TPU and 12.67g of composite methyl vinyl silicone rubber were added to the RM-200C torque rheometer, wherein the weight ratio of Si-TPU and VMQ in the composite methyl vinyl silicone rubber was 80:20, at 180 ° C Continuously mix for 7min until the torque is stable, then add 0.095g of Shuang 25, dynamically vulcanize for 9min, then add 2.2g of MAPP, 0.88g of MPP and 0.88g of EG and mix for 5min to obtain flame retardan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com