Composite heavy metal passivator and preparation method thereof

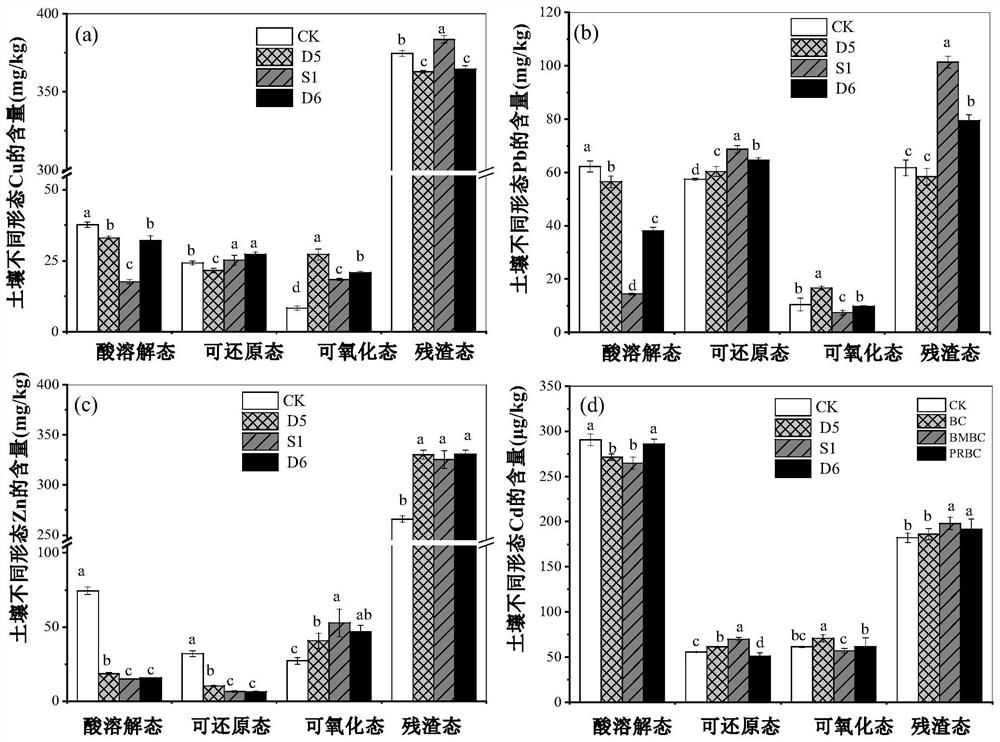

A heavy metal passivator and solvent technology, applied in chemical instruments and methods, fertilizer mixtures, other chemical processes, etc. Carbon function and other issues, to achieve good effect of passivating heavy metals in soil, realizing resource utilization and efficient utilization, and the effect of lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a composite heavy metal passivator, comprising the steps:

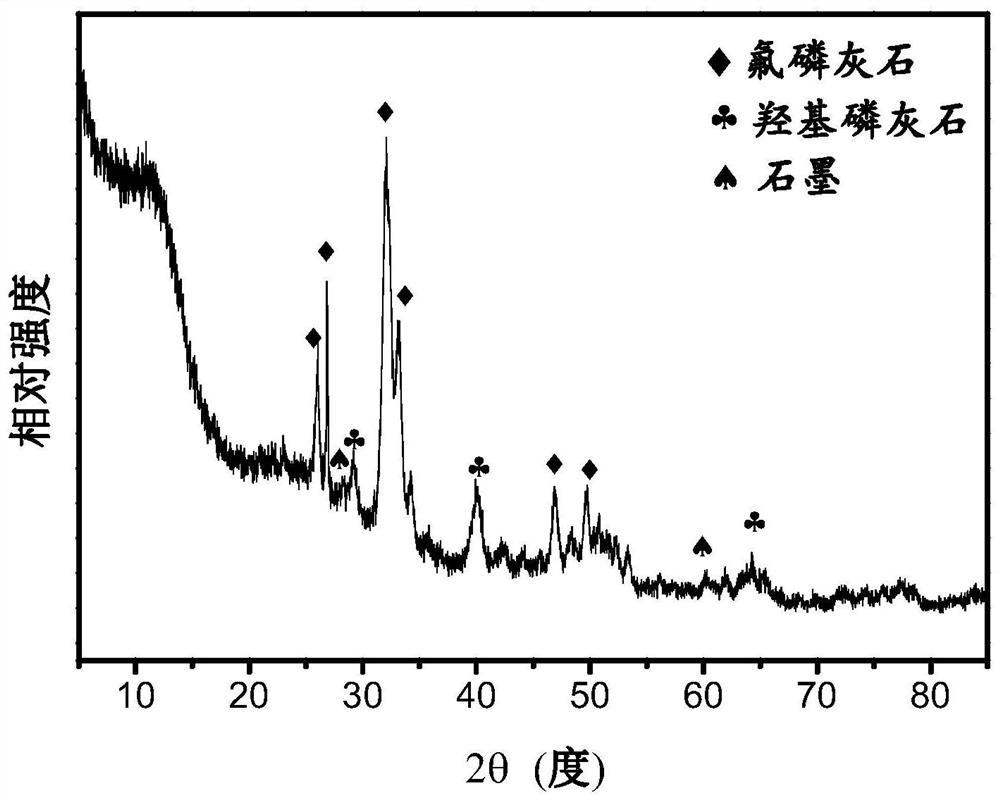

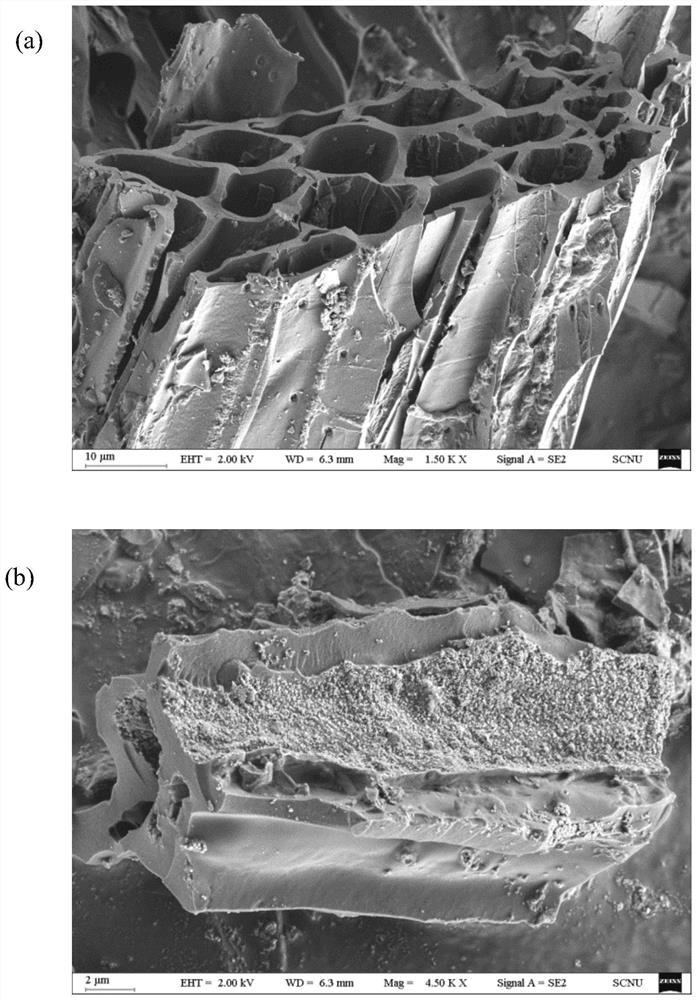

[0030] (1) 3 parts of bagasse and 2 parts of bovine bone meal are fully ground and pulverized and mixed, pass through a 100-mesh sieve, put into a closed incinerator, pass into nitrogen protection, create an oxygen-free environment, start heating at room temperature, and the heating rate is 10 ° C / min, after heating to 500°C, controlled at 500±10°C, isolated from air and heated for 3 hours to make biochar;

[0031] (2) take out the biochar obtained in step (1), put it into ethanol for immersion at room temperature for 15 minutes, continuously stir during the immersion, take out and filter, and keep the residue for air-drying;

[0032] (3) Put the air-dried biochar into 0.02mol / L dilute sulfuric acid, heat it in an airtight manner to a temperature of 70°C, keep stirring continuously during the heating process, keep it for 3h, then cool and filter, leave the residue, and put the residue a...

Embodiment 2

[0034] A preparation method of a composite heavy metal passivator, comprising the steps:

[0035] (1) 6 parts of bagasse and 1 part of bovine bone meal are fully ground and pulverized and mixed, pass through a 100-mesh sieve, put into a closed incinerator, pass into nitrogen protection, create an oxygen-free environment, start heating at room temperature, and the heating rate is 10 ° C / min; after the temperature rises to 500°C, control the temperature at 500±10°C, isolate the air and heat for 3 hours to make biochar;

[0036] (2) taking out the biochar obtained in step (1), soaking it in methanol for 15 minutes at room temperature, stirring continuously during the soaking, taking out and filtering, and keeping the residue for air-drying;

[0037] (3) Put the air-dried biochar into 0.04mol / L dilute hydrochloric acid, heat it in an airtight manner to a temperature of 70°C, keep stirring continuously during the heating process, keep it for 3h, then cool and filter, leave the res...

Embodiment 3

[0039] A preparation method of a composite heavy metal passivator, comprising the steps:

[0040] (1) 3 parts of bagasse and 1 part of bovine bone meal are fully ground and pulverized, mixed, passed through a 100-mesh sieve, put into a closed incinerator, protected by nitrogen, and an anaerobic environment is created. Start heating at room temperature, and the heating rate is 10 ° C / min; after the temperature rises to 500°C, control the temperature at 500±10°C, isolate the air and heat for 3 hours to make biochar;

[0041] (2) Take out the biochar, put it into ethanol for immersion at room temperature for 15 minutes, continuously stir during the immersion, take out and filter, and keep the residue for air-drying;

[0042](3) Put the air-dried biochar into 0.03mol / L dilute sulfuric acid, heat it in a closed place to a temperature of 70°C, keep stirring continuously during the heating process, keep it for 3h, then cool and filter, leave the residue, and put the residue at 65°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com