Wall-mounted ultrasonic enhanced fermentation device suitable for large fermentation tank and fermentation method of wall-mounted ultrasonic enhanced fermentation device

A fermentation device, ultrasonic technology, applied in the field of wall-mounted ultrasonic intensified fermentation device, can solve the problems of uneven ultrasonic effect, sound energy attenuation, large diameter and height, etc., to speed up the cleaning process, facilitate disassembly, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

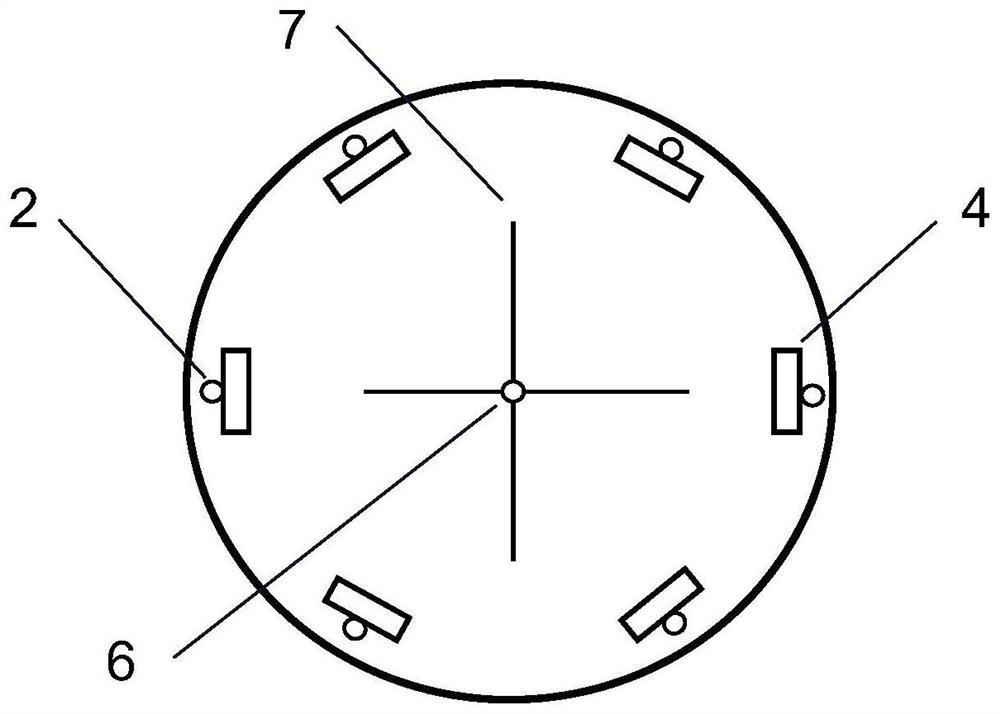

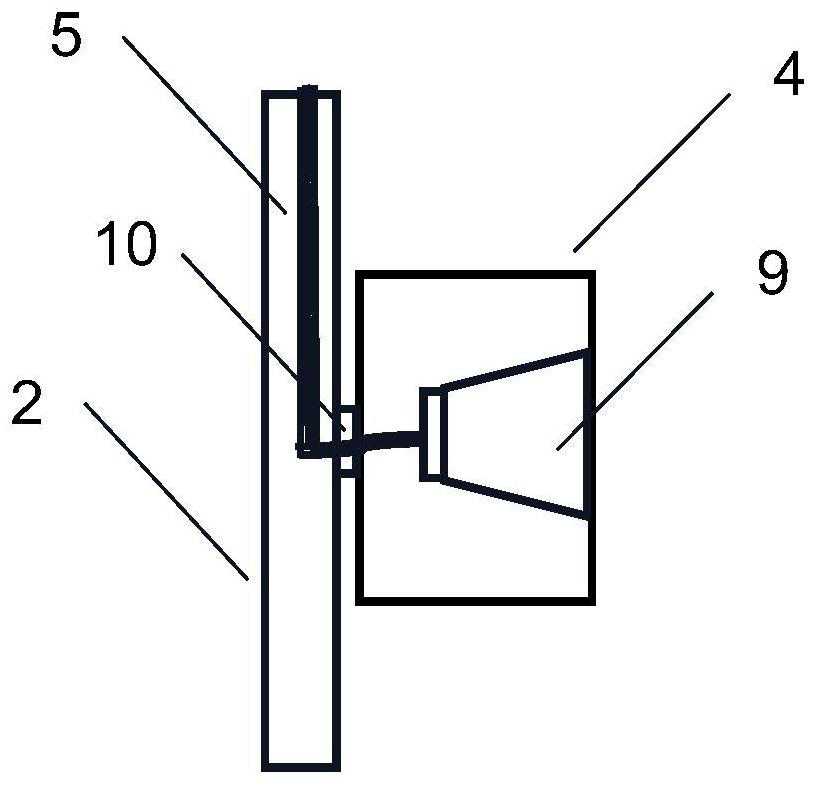

[0057] Follow the steps above at 40m 3 The fermentation tank is used for ultrasonic enhanced fermentation of Bacillus subtilis microbial inoculum. Fermentation tank 1 is equipped with four sets of wall-mounted ultrasonic transducer brackets 2, which are evenly arranged and suspended on the inner wall. Each bracket has three sections, which are sealed by stainless steel quick-release clamps. The bracket connectors 3 are connected, and 5 ultrasonic transducers 4 are arranged longitudinally in each section. The ultrasonic transducer bracket 2 is welded by the stainless steel welding short tube 10. There are 3 ultrasonic vibrators 9 in each transducer. 5 is electrically connected to the ultrasonic generator 8;

[0058] The specific fermentation is carried out as follows:

[0059] Step 1: Add fermented liquid to fermentation tank 1. Except for water, other substrates in the fermented liquid are 1.5% (w / v, hereinafter, all those not specified refer to mass volume concentration) soy...

Embodiment 2

[0068] at 40m 3 The fermenter carries out ultrasonic-enhanced fermentation for the production of transglutaminase (TG enzyme) by fermentation of Streptomyces. Connected by stainless steel quick-release clamp seal bracket connector 3, 5 ultrasonic transducers 4 are arranged longitudinally in each section, and ultrasonic transducer bracket 2 is welded by stainless steel welding short tube 10, each transducer has 3 ultrasonic vibrators 9. Electrically connect the ultrasonic generator 8 through the high-frequency connecting wire 5 .

[0069] The specific fermentation is carried out as follows:

[0070] Step 1: Fill the fermentation tank 1 with fermentation liquid. Except for water, the other substrates of the fermentation liquid are 2.4% soybean meal hydrolyzate, 2.4% glycerol, 0.5% yeast extract, 0.3% ammonium sulfate, and the fermentation tank is packed. The capacity is 75% volume. First, sterilize the fermenter tank 1, and the sterilization conditions are 121 ° C for 15 minu...

Embodiment 3

[0078] at 40m 3 The fermentation tank is used for ultrasonic-enhanced fermentation of cordyceps sinensis to produce mycelium and polysaccharides. Fermentation tank 1 is equipped with four sets of wall-mounted ultrasonic transducer brackets 2, which are evenly arranged and suspended on the inner wall. The clamp seal bracket connector 3 is connected, and 5 ultrasonic transducers 4 are arranged longitudinally in each section. The ultrasonic transducer bracket 2 is welded by the stainless steel welding short tube 10. There are 3 ultrasonic vibrators 9 in each transducer. The frequency connecting line 5 is electrically connected to the ultrasonic generator 8 .

[0079] The specific fermentation is carried out as follows:

[0080] Step 1: Add fermentation broth to fermentation tank 1, except water, other substrates are rice bran powder 3.6%, bran powder 4.8%, KH 2 PO 4 0.27%, MgSO 4 ·7H 2O 0.27%, cysteine hydrochloride 0.05%, copper chlorophyll sodium salt 0.01%, and the fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com