Method for etching MXene based on electrochemistry, MXene turbid liquid and application of MXene turbid liquid

An electrochemical and electro-etching technology, which is applied in chemical instruments and methods, inorganic chemistry, fiber chemical characteristics, etc., can solve the problems of easy operation danger, low safety factor of hydrothermal reaction, etc., and achieve the effect of economical and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

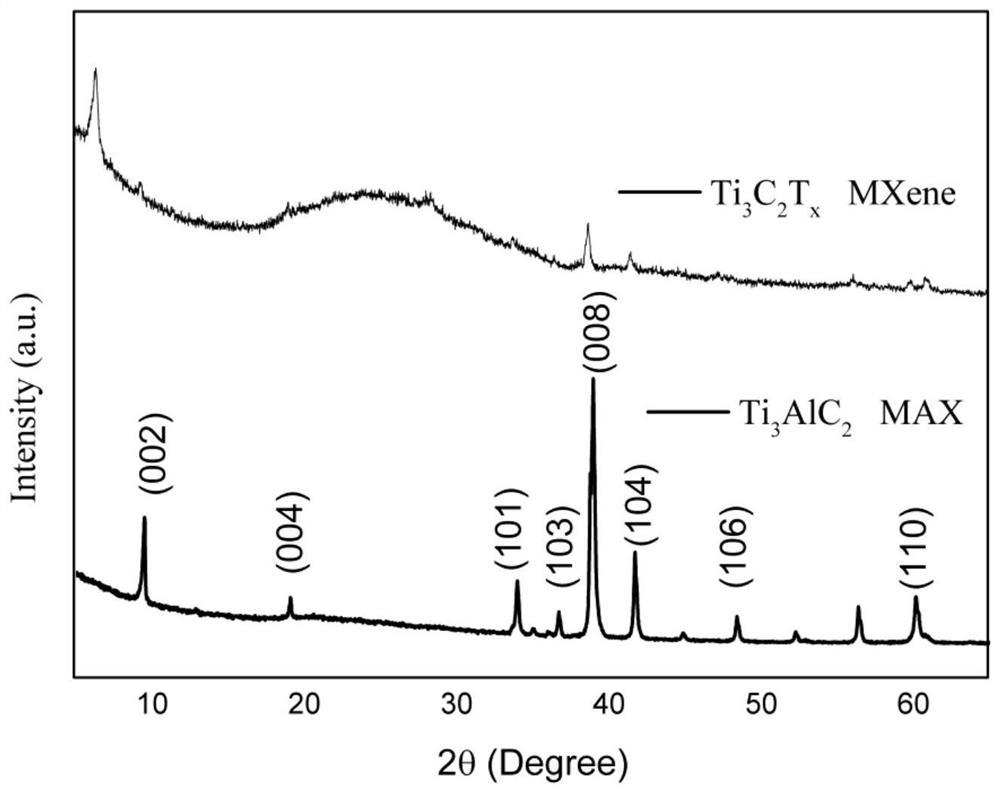

[0046] (a) Treatment of MAX phase (Ti 3 AlC 2 ) block. its initial mass m 1 It is 0.8331g, soaked in absolute ethanol, and ultrasonically treated for 10min to remove surface dust, and then placed in an oven to dry for use.

[0047] (b) Configure the electro-etching solution. Take N-N-dimethylformamide (DMF) as a solvent, add tetrabutylammonium chloride tetrahydrate (TBAF) to it, prepare an electrolyte with a molar concentration of 0.5mol / L, and take 50ml of it for subsequent use after fully stirring and dissolving. ;

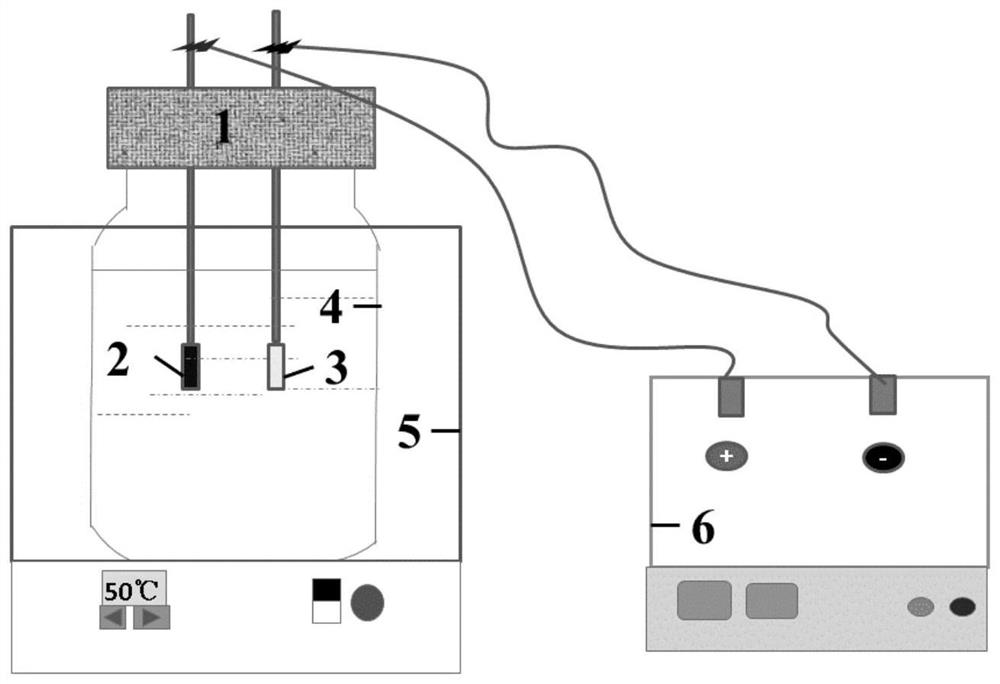

[0048] (c) Assembly of the two-electrode device. Pour the electro-etching solution prepared in step (b) into an electrolytic cell, wherein the Ti treated in step (a) 3 AlC 2 The block is the working electrode, the platinum sheet is the counter electrode, and the two electrodes are inserted into the electrolyte in parallel.

[0049] (d) The electrolytic cell assembled in step (c) was placed in a water bath to maintain a constant reaction temperature of 49...

Embodiment 2

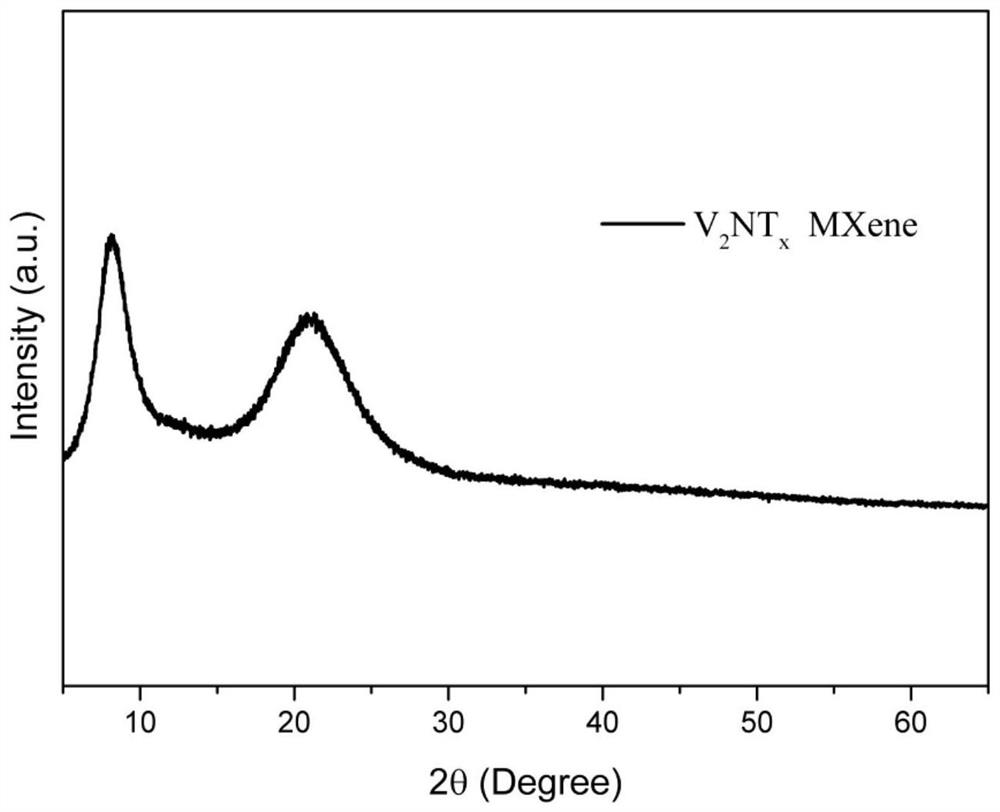

[0056] (a) Processing MAX phase (V 2 GaN) bulk: initial mass m 1 For 2.684g, soak the MAX with absolute ethanol and ultrasonically treat it for 10min to remove surface dust, and then put it in an oven to dry for use.

[0057] (b) Configure the electro-etching solution. Take propylene carbonate (PC) as solvent, add a certain amount of ammonium bifluoride (NHF) to it 4 HF 2 ) so that the molar concentration of the solution is 4 mol / L, and after fully stirring and dissolving, 120 ml is weighed for subsequent use.

[0058] (c) Assembly of the two-electrode device. Pour the electro-etching solution prepared in step (b) into an electrolytic cell, wherein the V treated in step (a) 2 The GaN bulk is the working electrode, the nickel sheet is the counter electrode, and the two electrodes are kept parallel and inserted into the electrolyte.

[0059] (d) The electrolytic cell assembled in step (c) is placed in a water bath to maintain a constant reaction temperature of 50°C.

[00...

Embodiment 3

[0066] (a) Treatment of MAX phase (Cr 2 GeC) bulk. initial mass m 1 For 2.464g, soak MAX in absolute ethanol and ultrasonically treat it for 10min to remove surface dust, and then put it in an oven to dry for use;

[0067] (b) Configure the electro-etching solution. Take dimethylacetamide (DMAC) as solvent, add a certain amount of ammonium bifluoride (NHF) to it 4 HF 2 ) make the solution concentration be that the molar concentration is 0.8mol / L, after fully stirring and dissolving, take by weighing 60ml for subsequent use;

[0068] (c) Assembly of the two-electrode device. Pour the electro-etching solution prepared in step (b) into an electrolytic cell, wherein the Cr treated in step (a) 2 The GeC block is the working electrode, the graphite sheet is the counter electrode, and the two electrodes are inserted into the electrolyte in parallel;

[0069] (d) the electrolytic cell assembled by step (c) is placed in a water bath to maintain a constant 70°C reaction temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com