Silk protein-based sweat-wet-resistant flexible pressure sensor and method and application thereof

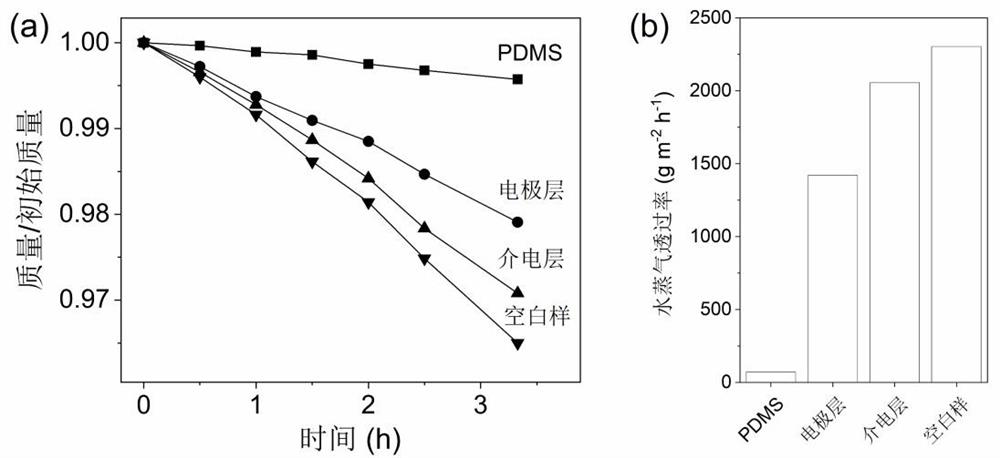

A pressure sensor and silk protein technology, applied in the field of materials, can solve problems such as allergies, low biocompatibility, and device failure, and achieve high anti-sweat performance, high biocompatibility, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

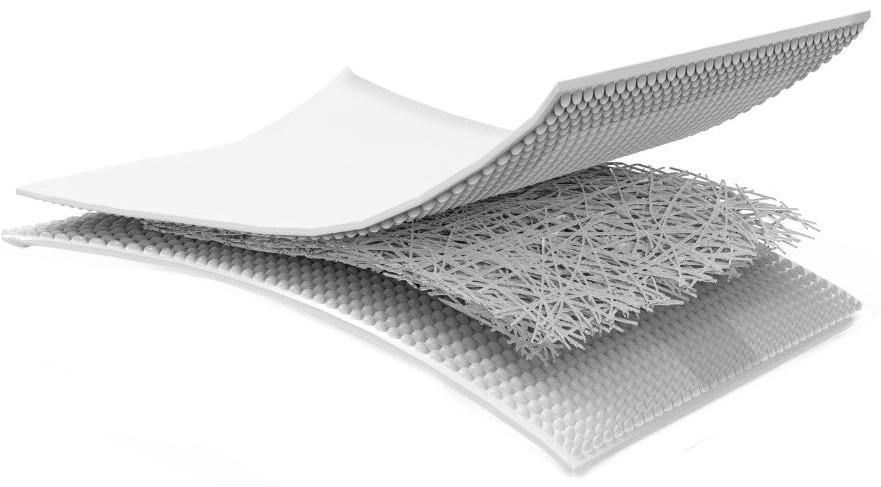

[0051] Example 1: Flexible pressure sensor based on microstructured electrode layers and ionic dielectric layers

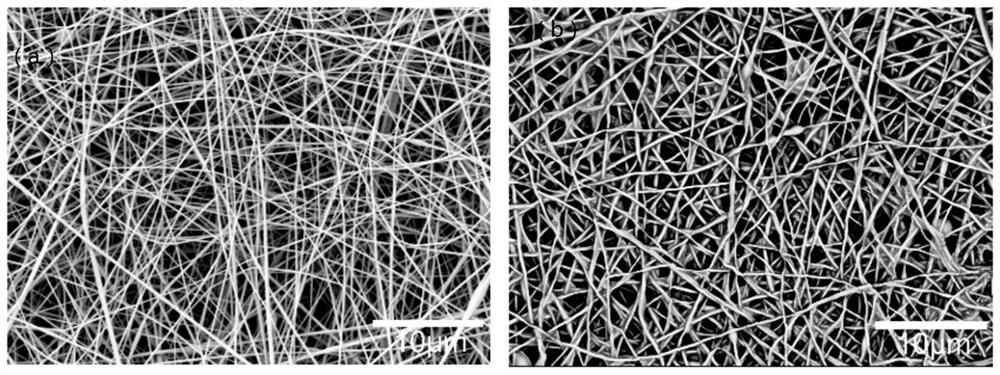

[0052] (1) Preparation of ionic dielectric layer: a formic acid solution of fibroin with a concentration of 15wt% was prepared, and a silk fibroin fiber felt was obtained by an electrospinning process. The spinning voltage was 12kV, the feeding rate was 0.02ml / h, and the collection distance was is 15cm;

[0053] Preparation of choline chloride: glycerol molar ratio of 1:1 deep eutectic solvent for use, the silk fibroin fiber felt is treated with ethanol solution, soaked in the deep eutectic solvent, and dried to obtain silk fibroin / ionic liquid fiber felt as a pressure sensor ionic dielectric layer.

[0054] (2) Preparation of microstructured electrode layer: add 20wt% glycerin of silk protein to 15wt% fibroin in formic acid solution, then scrape it on a 600-mesh sandpaper substrate, and dry to obtain fibroin with a microprotrusion structure membrane; and then s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com