Low-temperature negative black photoresist composition and black matrix thereof

A technology of composition and photoresist, applied in the direction of nonlinear optics, optics, optomechanical equipment, etc., can solve the problems of peeling, poor chemical resistance, insufficient strength, etc., to improve adhesion, reduce impact, increase strength and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] 15g photocurable resin (A), 3g photopolymerizable monomer (B) dipentaerythritol pentaacrylate, 1g photoinitiator (D), black color paste (E), low temperature blocked isocyanate crosslinking agent (F) and 0.02 g Surfactant (G) was uniformly mixed, the mixture was dissolved in propylene glycol methyl ether acetate so that the solid content of the mixture was 14 parts by weight, the solution was stirred for 2 hours, and filtered through a membrane filter with a pore size of 0.2 μm , to obtain a composition solution with a solid content of 14 parts by weight.

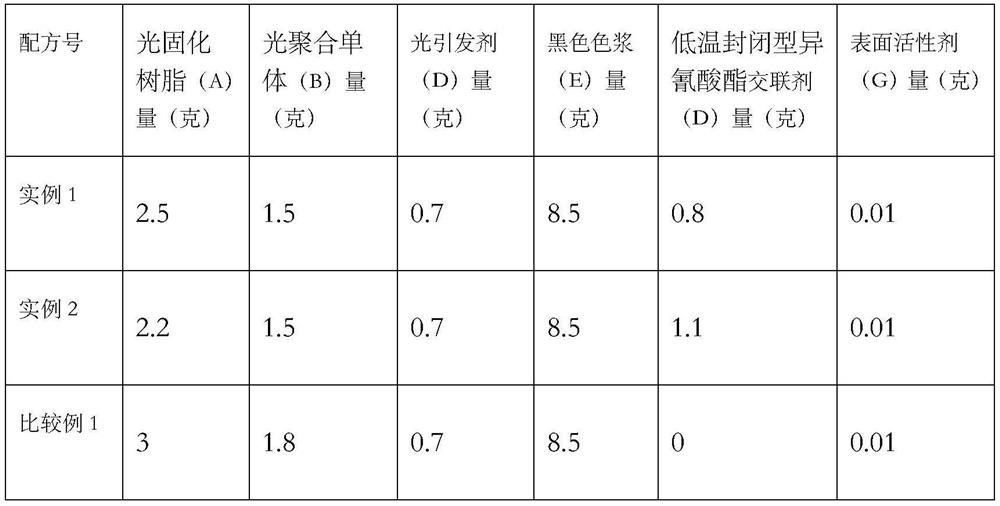

example 2 and comparative example 1

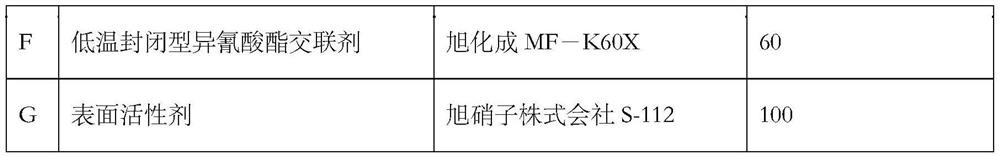

[0039] The photoresist compositions were each prepared in the same manner as in Example 1, except that the contents of the respective components were varied as shown in Table 2:

[0040] Table 2

[0041]

[0042] Prepare the black matrix:

[0043] The photoresist compositions obtained in each example and comparative example are coated on a substrate, subjected to a prebake at a temperature of 60°C to 130°C to remove the solvent; then exposed using a photomask having a desired pattern; and undergo development using a developer, which may be a potassium hydroxide solution, to form a pattern on the coating, post-bake the patterned coating at a temperature of 80°C to 120°C for 10 minutes to 5 hours, In order to prepare the desired cured film, exposure is performed in the wavelength band of 200 to 500 nm based on the wavelength of 365 nm, at 10 to 200 mJ / cm 2 The exposure rate is carried out to obtain the target pattern for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com