Manganese-based ternary integrated difunctional oxygen electrode and preparation method and application thereof

A manganese-based ternary, bifunctional technology, applied in the field of electrocatalysis, can solve the problems of poor stability of cobalt-based transition metal oxides, low conductivity and poor stability of manganese oxides, and achieves improved catalyst performance, improved conductivity, The effect of improving oxygen evolution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

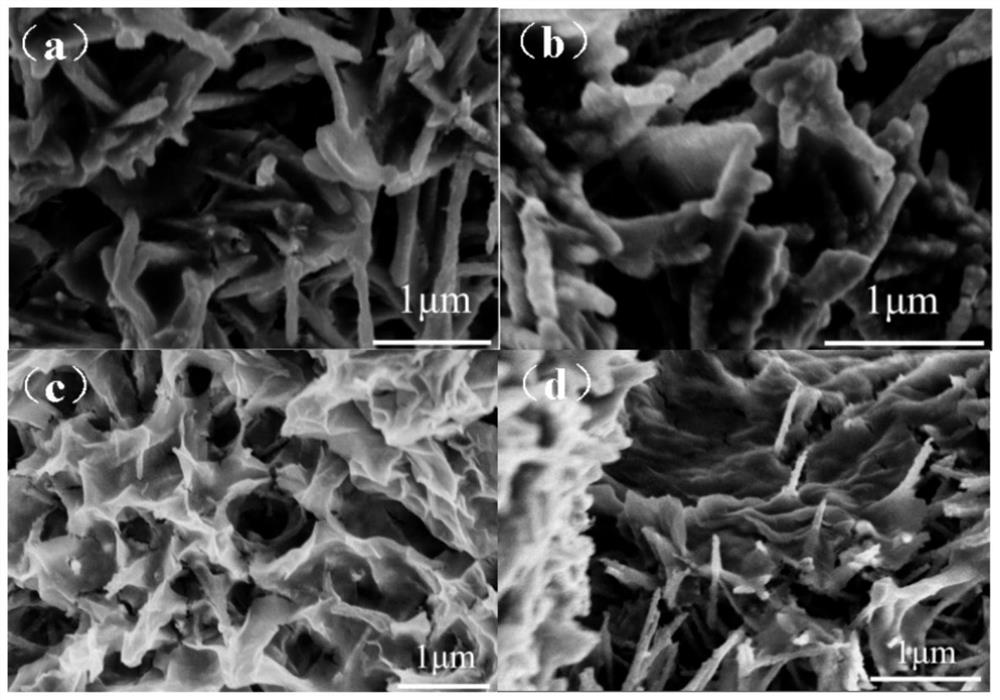

[0033] This embodiment provides a manganese-based ternary integrated bifunctional oxygen electrode (NiCo 2 O 4 / MnO 2 / C@Ni-Foam) preparation method, the specific preparation steps are as follows:

[0034] Step 1: Put 0.79g KMnO 4 Add 50 mL of deionized water, stir until the crystals disappear, and continue to sonicate to ensure complete dissolution;

[0035] Step 2: 2ml (12mol / L) hydrochloric acid was added to the solution of step 1, transferred to the reaction kettle, and reacted at 140°C for 12 hours;

[0036] Step 3: Centrifuge step 2), wash with water and alcohol, dry the collected precipitate at 70°C, and obtain MnO after structural characterization 2Tubular crystals, i.e. MnO 2 nanotube;

[0037] Step 4: Put 0.249gCo(Ac) 2 ·4H 2 O and 0.248g Ni(Ac) 2 ·4H 2 O and 20mg carbon nanotubes (diameter 20~30nm, purity>98%wt, Zhongke Times Nano Center) add 30mL ammonia water, stir until the crystal disappears, continue to ultrasonically vibrate to ensure complete dissol...

Embodiment 2

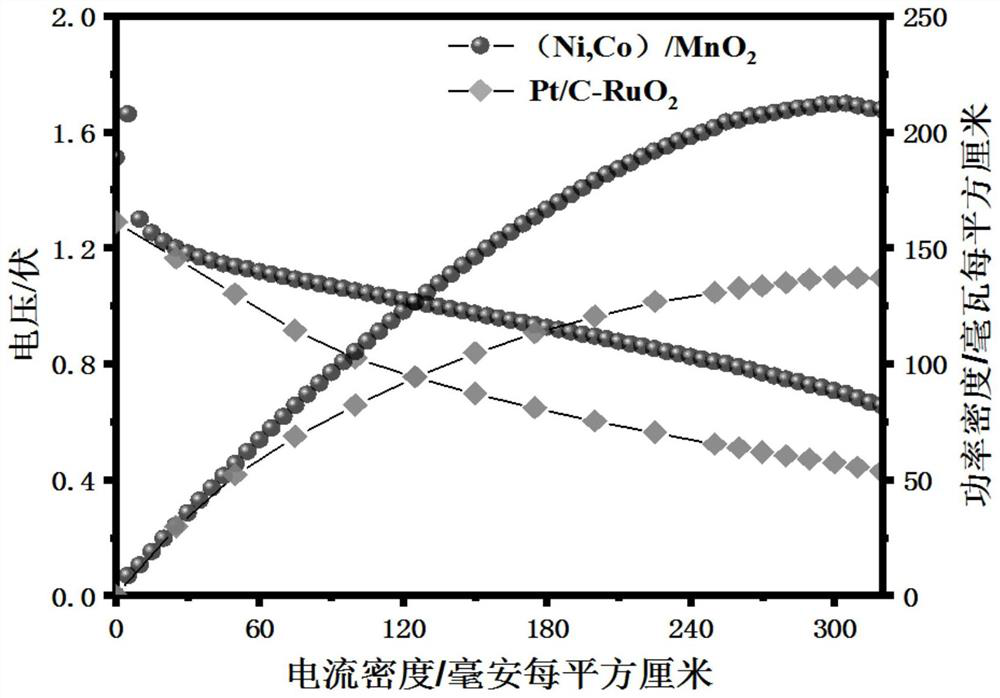

[0067] 10 mg of the bifunctional oxygen electrodes prepared in Example 1 and Comparative Examples 1 to 3 were mixed with Pt / C-RuO 2 The powder was dissolved in ethanol and 5% Nafion solution, sonicated for 30 minutes to form a uniform catalyst slurry, and then spread on hydrophobic treated carbon paper (loading 2 mg / cm2). 2 ), and dried at 50°C for 40 minutes to prepare an air electrode. Using zinc foil as the negative electrode, the air electrode, zinc foil and 6 mol / L potassium hydroxide solution were put into the self-made zinc-air battery tank, and the blue electricity system was used for testing. . The test conditions are from 1 mA to 350 mA of gradual discharge with a rate of change of 1 mA / s.

[0068] Test results such as Figure 2a , 2b shown, Figure 2a NiCo prepared for Example 1 2 O 4 / MnO 2 / C@Ni-Foam catalyst and commercial Pt / C-RuO 2 The power comparison of the catalyst shows that (Ni,Co) / MnO 2 The peak power of 210mW / cm 2 Significantly better than Pt / C...

Embodiment 3

[0070] 10 mg of the bifunctional oxygen electrodes prepared in Example 1 and Comparative Examples 1 to 3 were mixed with Pt / C-RuO 2 The powder was dissolved in ethanol and 5% Nafion solution, sonicated for 30 minutes to form a uniform catalyst slurry, and then spread on hydrophobic treated carbon paper (loading 2 mg / cm2). 2 ), and dried at 50°C for 40 minutes to prepare an air electrode. Using zinc foil as the negative electrode, the air electrode, zinc foil and 6 mol / L potassium hydroxide solution were put into the self-made zinc-air battery tank, and the blue electricity system was used for testing. . Test condition 5mA / cm 2 Current density, 10 min full electrical cycle time.

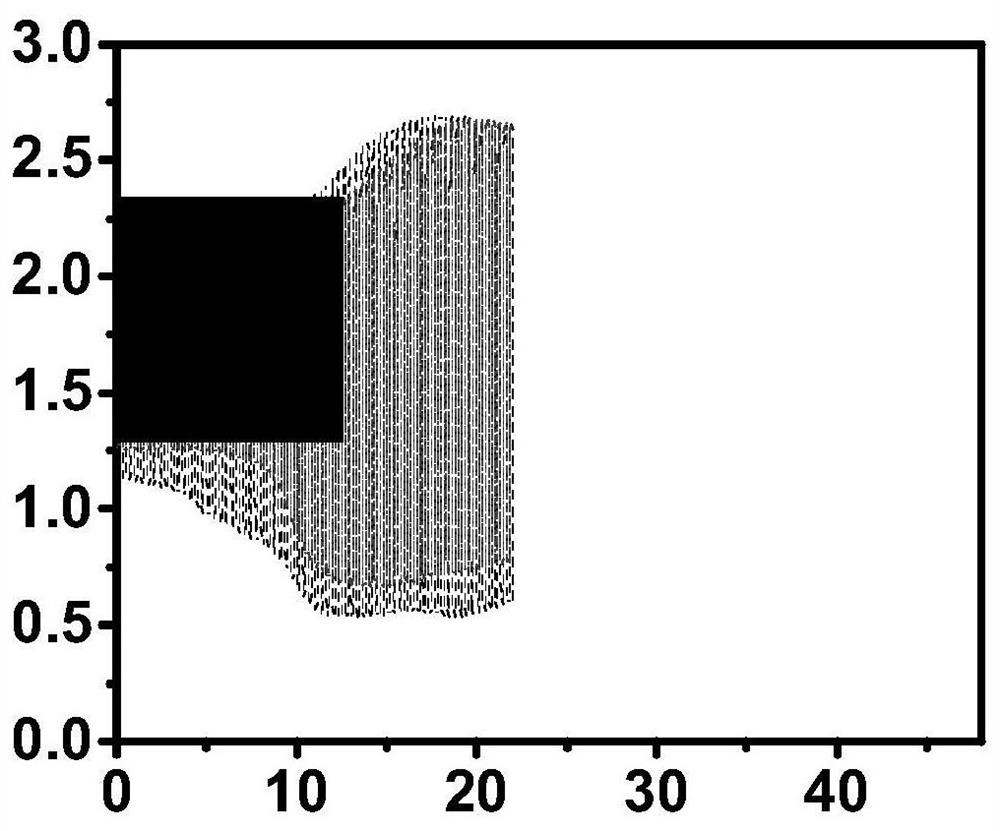

[0071] Test results such as Figure 3a , 3b shown, it can be seen that at 5mA / cm 2 NiCo synthesized in Example 1 during constant current charge and discharge 2 O 4 / MnO 2 The / C@Ni-Foam catalyst has a larger open circuit voltage and discharge time (43h), the discharge voltage is maintained at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com