Application of polyethyleneimine-cellulose composite gel

A technology of polyethylenimine and composite gel, which is applied in applications, chemicals for biological control, biocides, etc., can solve problems such as limited use scenarios, achieve the effect of inhibiting spoilage, and effectively prevent and control rice blast and melon blight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Preparation of oxidized cellulose

[0026] Configure 100ml of 70wt% sulfuric acid aqueous solution, put 10g corncob cellulose into the sulfuric acid aqueous solution, stir until the solution is transparent (about 30 minutes), add 10 times of water to dilute and centrifuge to remove the supernatant, collect the hydrolyzed cellulose and wash with water . Sampling and drying, the yield of hydrolyzed cellulose was determined according to the gravimetric method to be 55%. Take the cellulose hydrolyzate, dilute it to 5% (w / w), add sodium periodate to react at a reaction time of 1-7h, pH 2-8, feed ratio: 0.5:1-5:1, and then add The reaction was terminated by ethylene glycol, and the oxidized cellulose was obtained by dialysis and freeze-drying after taking out.

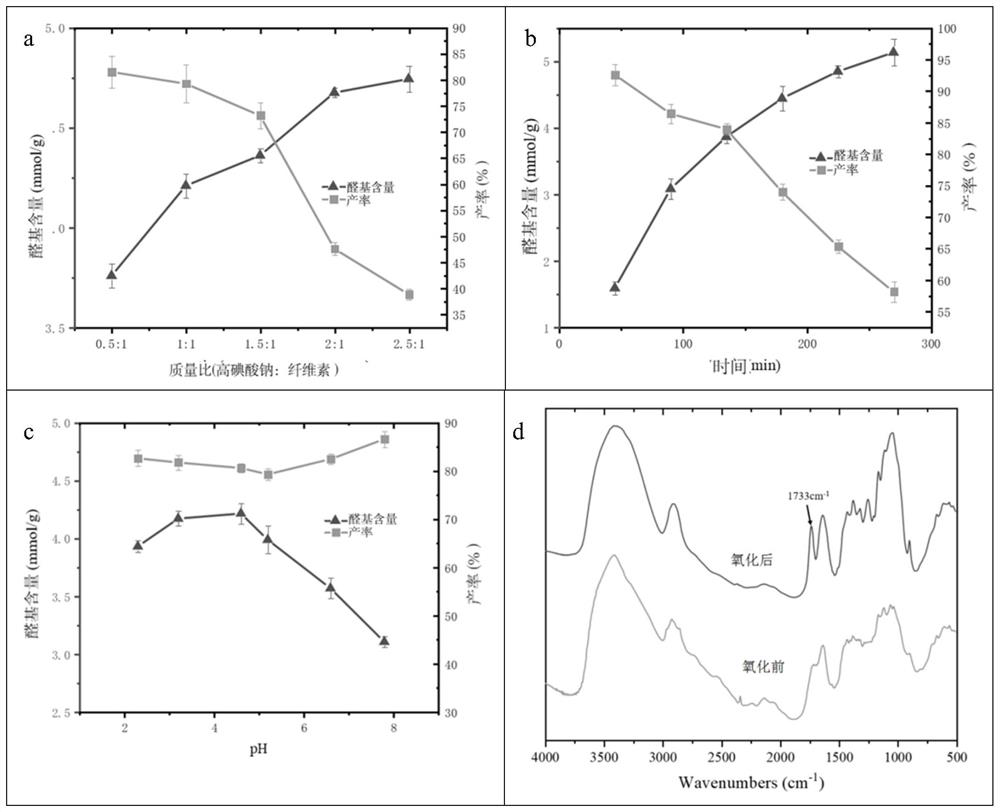

[0027] Feed ratio (reaction time 3h, pH 6), oxidation reaction time (pH 4, feed ratio 1.5:1), pH (reaction time 3h, feed ratio 1.5:1) three reaction conditions and the relationship between aldehyde group ...

Embodiment 2

[0028] Example 2: Preparation of polyethyleneimine-cellulose composite gel

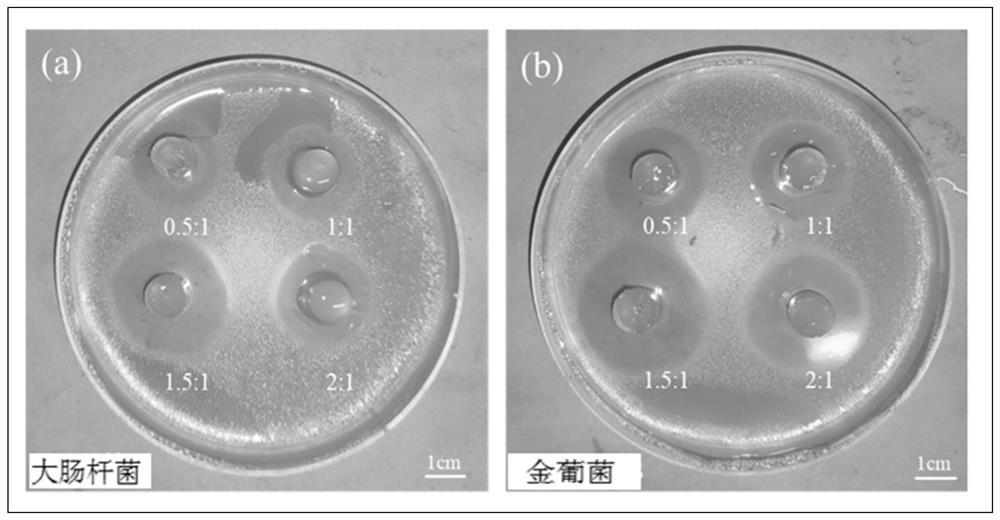

[0029] Mix 5wt% polyethyleneimine (molecular weight 70000Da, pH 7) solution with 5wt% oxidized cellulose (pH 7) in volume ratios of 0.5:1, 1:1, 1.5:1 and 2:1, and inject with a pore size of The hydrogel was formed in a 9mm, 6mm height PDMS mold hole. All groups were gelatinized within 1 minute and left for 12h to fully gelatinize before taking out the hydrogel and immersing it in sterile water for equilibrium.

Embodiment 3

[0030] Example 3: Preparation of polyethyleneimine-cellulose composite gel

[0031] Mix 10wt% polyethyleneimine (molecular weight 10000Da, pH 7) solution with 3wt% carboxymethyl cellulose (pH 7) in volume ratio 0.5:1, 1:1, 1.5:1 and 2:1, add 0.1 wt% N-hydroxysuccinimide (NHS) and 0.1 wt% carbodiimide (EDC) were injected into a PDMS mold hole with a pore diameter of 9 mm and a height of 6 mm to form a hydrogel. All groups were gelled after being placed at room temperature for 12 hours, and then the hydrogels were taken out and immersed in sterile water for equilibrium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com