Deodorized soybean protein powder and preparation method thereof

A technology of soybean protein powder and protein slurry, which is applied to the protein composition of vegetable seeds, protein food ingredients, food science, etc., can solve the problems of increasing food risk, reducing product purity, slow dissolution, etc., and achieve improved enzymatic hydrolysis effect , Improve solubility performance, solubility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

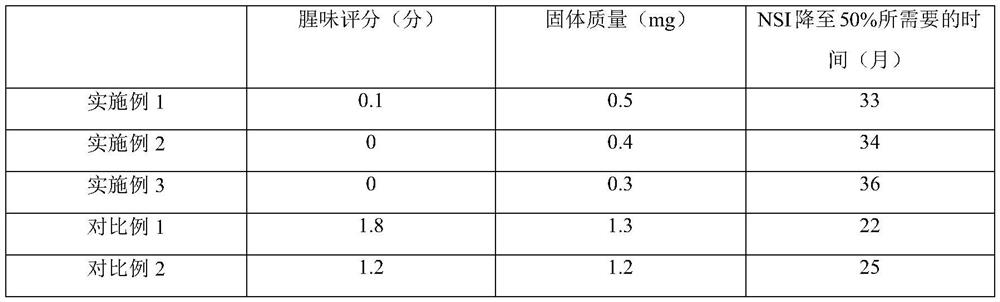

Examples

Embodiment 1

[0037] A preparation method of deodorized soybean protein powder, the concrete steps are as follows:

[0038] (1) First add 3kg of low-temperature defatted soybean meal to 25kg of water, ultrasonically vibrate, continue to add 0.5kg of phytase and 0.4kg of acid protease, stir and mix to obtain a mixed slurry, aerate enzymatic hydrolysis treatment with oxygen, inactivate enzymes, and centrifuge to get The supernatant was adjusted to pH=4 with food-grade hydrochloric acid to precipitate soybean protein, centrifuged again to get the precipitate, then ultrasonically dispersed the precipitate in 15kg of water, and adjusted pH=7 to obtain a protein slurry with a solid content of 10w.t.%;

[0039] (2) The protein slurry is then subjected to high-voltage pulsed electric field treatment, and then 0.02 kg of glucose and 0.01 kg of yeast extract are added to perform partial Maillard reaction to obtain a pretreated protein solution;

[0040] (3) Finally, the pretreated protein solution is s...

Embodiment 2

[0050] A preparation method of deodorized soybean protein powder, the concrete steps are as follows:

[0051] (1) First add 5kg of low-temperature defatted soybean meal to 30kg of water, ultrasonically vibrate, continue to add 0.6kg of phytase and 0.5kg of acid protease, stir and mix to obtain a mixed slurry, aerate the enzymatic hydrolysis treatment with oxygen, inactivate the enzyme, and extract by centrifugation. The supernatant was adjusted to pH=5 with food-grade hydrochloric acid, and the soybean protein was precipitated, and the precipitate was obtained by centrifugation again. Then, the precipitate was ultrasonically dispersed in 20 kg of water, and adjusted to pH=7 to obtain a protein slurry with a solid content of 12w.t.%;

[0052] (2) The protein slurry is then subjected to high-voltage pulsed electric field treatment, and then 0.03 kg of glucose and 0.02 kg of yeast extract are added to perform partial Maillard reaction to obtain a pretreated protein solution;

[0...

Embodiment 3

[0063] A preparation method of deodorized soybean protein powder, the concrete steps are as follows:

[0064] (1) First add 4kg of low-temperature defatted soybean meal to 28kg of water, ultrasonically vibrate, continue to add 0.55kg of phytase and 0.45kg of acid protease, stir and mix to obtain a mixed slurry, aeration and enzymolysis treatment, inactivate enzymes, and centrifuge to get The supernatant was adjusted to pH=5 with food-grade hydrochloric acid to precipitate soybean protein, centrifuged again to get the precipitate, then ultrasonically dispersed the precipitate in 18kg water, and adjusted pH=7 to obtain a protein slurry with a solid content of 11w.t.%;

[0065] (2) The protein slurry is then subjected to high-voltage pulsed electric field treatment, and then 0.025 kg of glucose and 0.015 kg of yeast extract are added to perform partial Maillard reaction to obtain a pretreated protein solution;

[0066] (3) Finally, the pretreated protein solution is subjected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com