Preparation method of bone defect repair stent

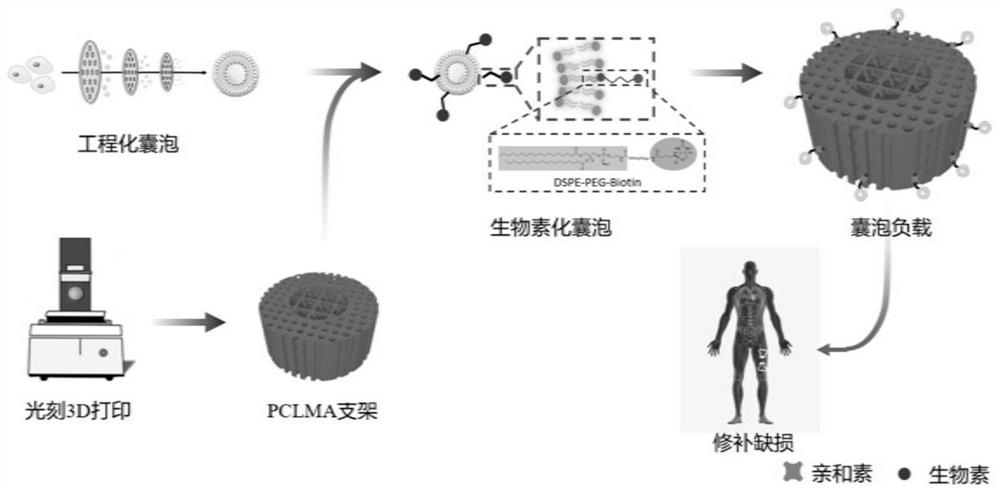

A bone defect and bone repair technology, applied in the direction of bone implants, can solve the problems of lack of biological activity and poor mechanical properties, and achieve the effect of promoting regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for manufacturing a scaffold for repairing bone defects, comprising the following steps:

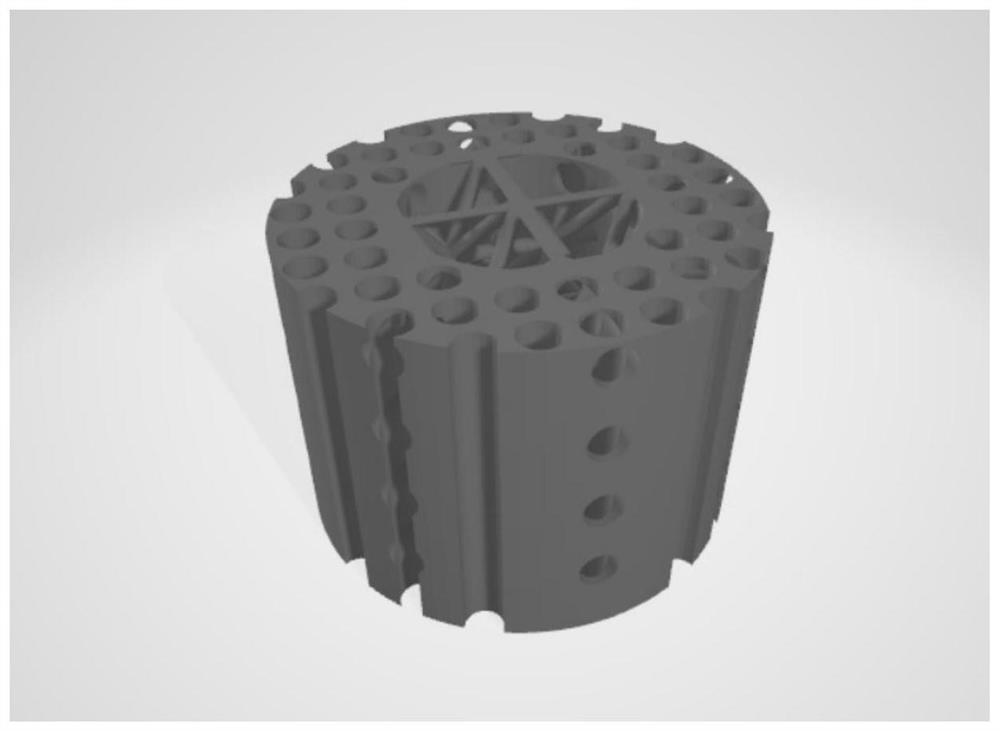

[0041] (1) The patient took the CT of the bone defect before the operation, saved it in DICOM format and imported it into the surgical planning software (ProPlan 2.1, Materialise NV, Belgium), and reconstructed the three-dimensional model of the defect. The software can then automatically generate the required bone tissue length, diameter, and surgical plan. Export the scheme to CAD software in STL format;

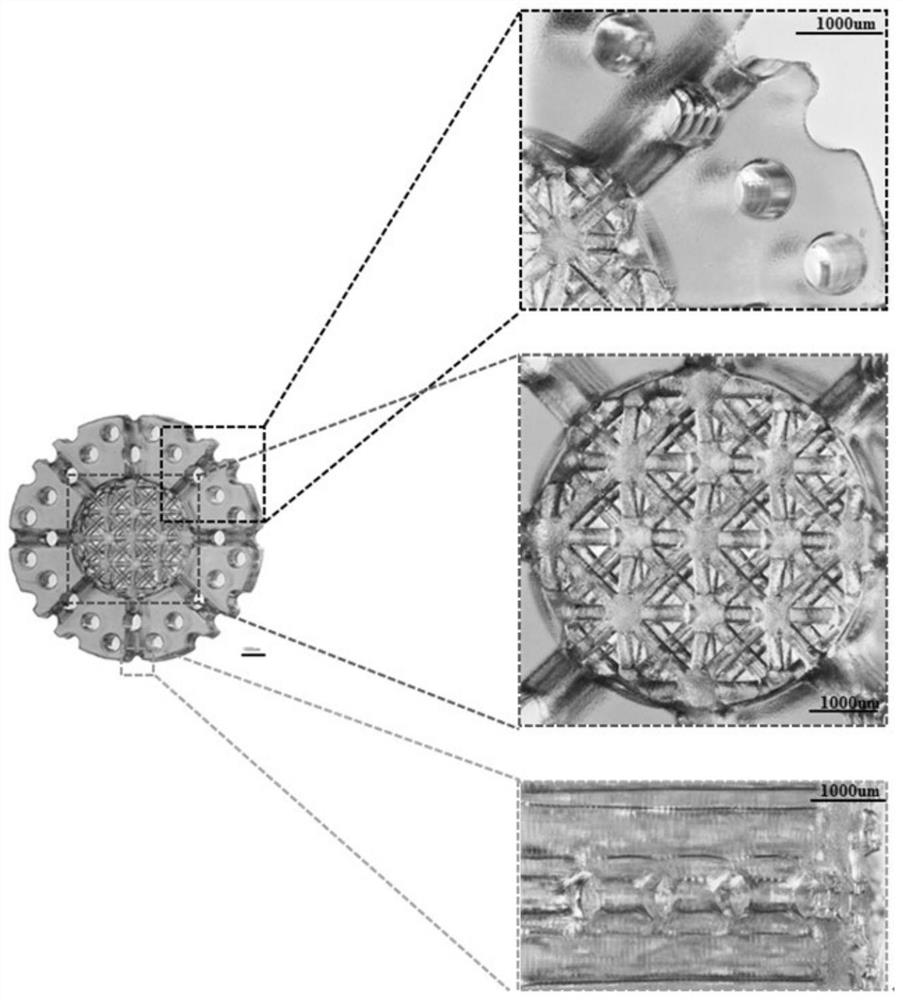

[0042] (3) The photoinitiator TPO-L was dissolved in photocurable polycaprolactone (PCLMA) at a concentration of 1.8% w / v and the light absorber β-carotene at a concentration of 0.09% w / v, to obtain a bone scaffold that can be used for printing. liquid ink;

[0043] (4) Aseptically treating the bone scaffold printing liquid ink obtained in step (3), adding a centrifuge tube, repeatedly blowing and beating with a pipette, and placing it in a centrifuge at 3700 r / min fo...

Embodiment 2

[0054] A method for manufacturing a scaffold for repairing bone defects, comprising the following steps:

[0055] (1) Obtain the imaging data of the patient's bone defect through clinical imaging CT and MRI scanning, and then use CAD software to perform 3D modeling to obtain slice STL format files;

[0056] (2) Based on the above data analysis and model making, a personalized bone repair scaffold with a specific shape suitable for the patient's bone defect is designed;

[0057] (3) The photoinitiator TPO-L was dissolved in photo-curable polycaprolactone (PCLMA) at a concentration of 1.5% w / v and the light absorber β-carotene at a concentration of 0.06% w / v to obtain a bone scaffold that can be used for printing. liquid ink;

[0058] (4) Aseptic treatment of the bone scaffold printing liquid ink obtained in step (3), adding a centrifuge tube, repeatedly blowing and beating with a pipette gun, and placing it in a centrifuge at 3500 r / min for 3 minutes to remove air bubbles, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com