Long-acting micro-odor aroma-releasing type flame-retardant carbon nanospheres and wood board containing same

A technology of carbon nanospheres and wooden boards, applied in the direction of nano-carbon, wood impregnation, impregnated wood, etc., can solve the problems of complex manufacturing process, decreased bending strength, high cost, etc., and achieve high mechanical strength and excellent flame retardancy , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

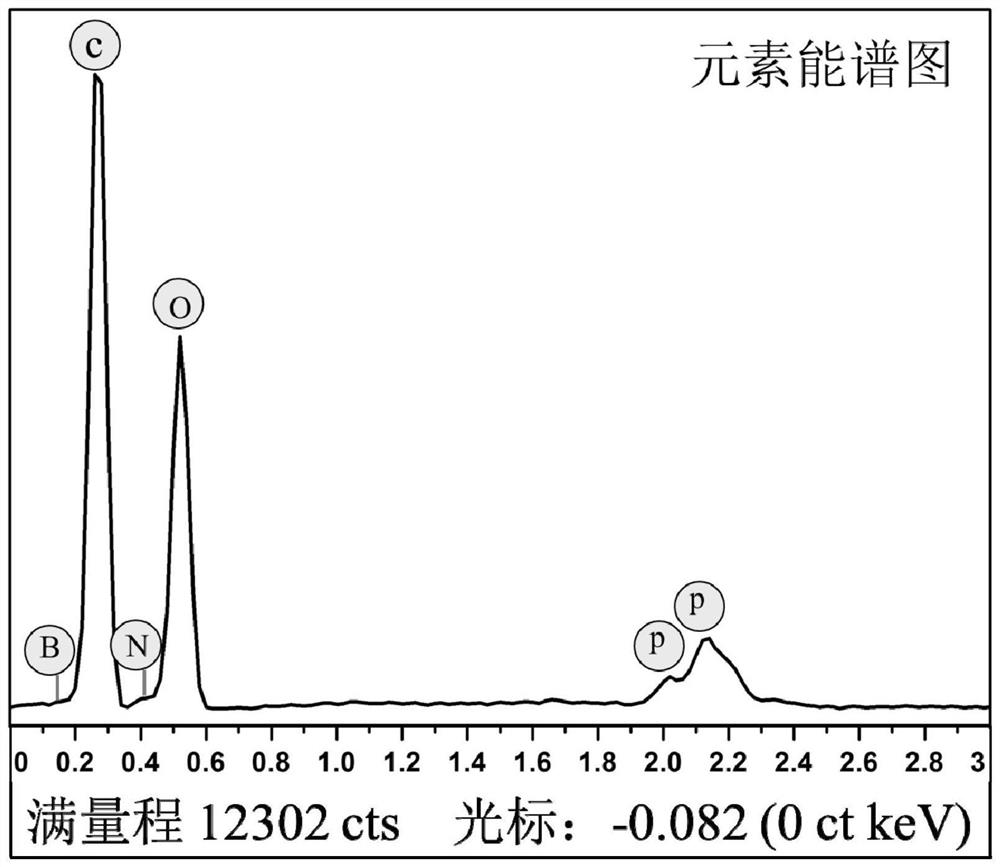

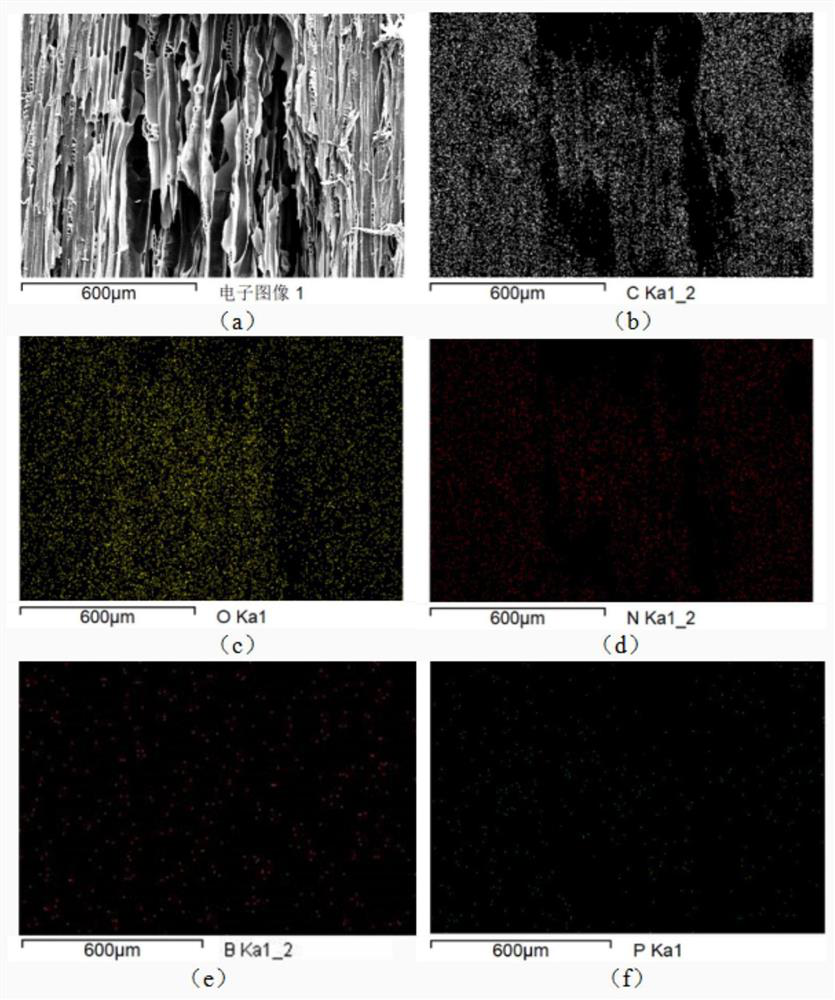

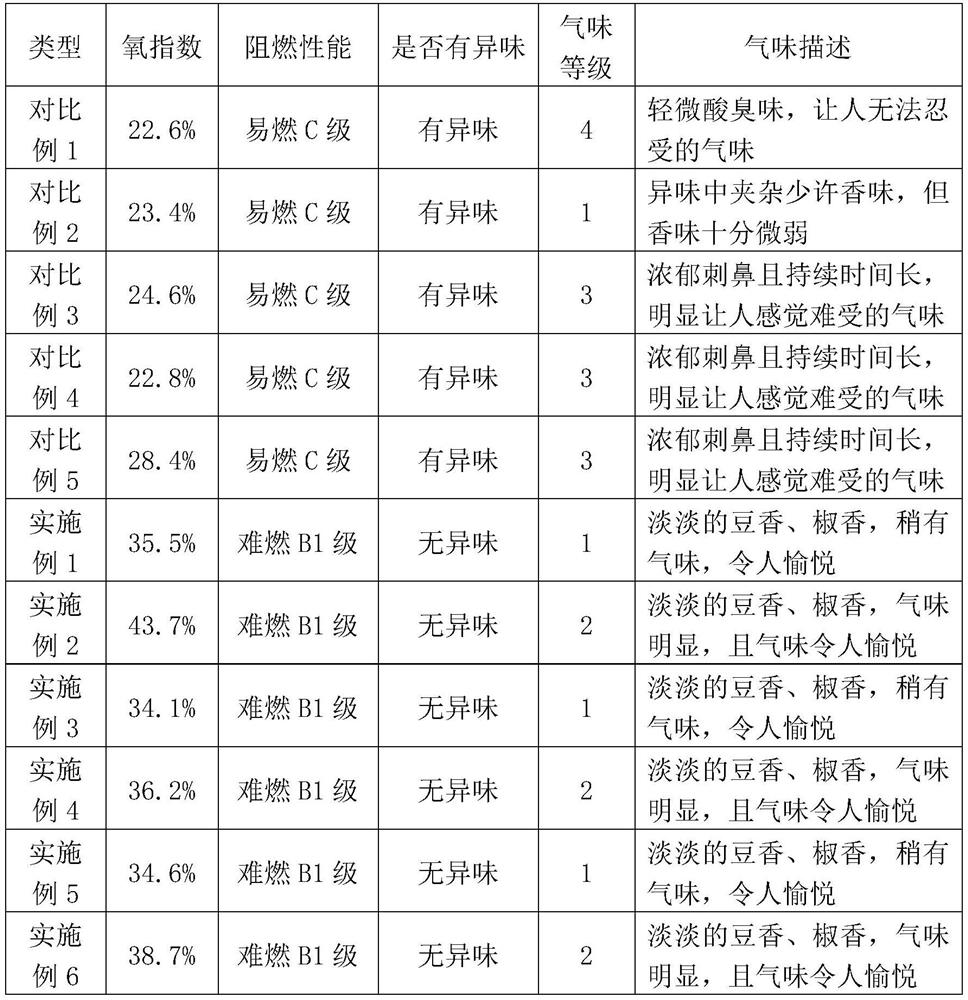

[0075] Preparation Example 1 Preparation of long-acting, slightly odor-releasing, flame-retardant carbon nanospheres

[0076] 1) First take 3.2g of red pepper shells, configure a water / alcohol mixed solvent, wherein the mass ratio of water and ethanol is 5:1, and the pepper mixture (absolute dry mass) is mixed with the mixed solvent in a mass ratio of 2:100, 80 The solvothermal reaction was carried out at ℃ for 60 min. Then, the filtrate was collected by filtration through a 200-mesh filter screen, and the solid residue was collected.

[0077] 2) Physically pulverize the solid residue to a particle size range of 80 meshes, add 1% mass fraction of polyvinyl alcohol based on the absolute dry mass of the solid residue, mix thoroughly, and use it as an adhesive admixture for later use.

[0078] 3) Mix the above-mentioned prickly ash shell filtrate, soybean protein isolate, and phenylboronic acid functional adjuvant according to a mass ratio of 100:0.05:0.5, and fully magnetically...

preparation example 2

[0083] Preparation Example 2 Preparation of long-acting, slightly odor-releasing, flame-retardant carbon nanospheres

[0084] The only difference from Preparation Example 1 is that the temperature of the solvothermal reaction in step 1) is 60° C. and the time is 45 min.

[0085] The elemental analysis shows that its elemental composition includes: 40.2% C, 6.1% N, 48.2% O, 4.8% B, and 0.7% P.

[0086] The X-ray electron spectrum analysis showed that the surface contained 3.6% amino group, 14.5% carboxyl group, 11.4% hydroxyl group and 4.6% boron hydroxyl group.

[0087] The transmission electron microscope analysis showed that the average particle size of the carbon nanospheres was 7.24 nm.

preparation example 3

[0088] Preparation Example 3 Preparation of long-acting, slightly odor-releasing, flame-retardant carbon nanospheres

[0089] The only difference from Preparation Example 1 is that the temperature of the solvothermal reaction in step 1) is 95° C. and the time is 90 min.

[0090] The elemental analysis shows that its elemental composition includes: 41.8% C, 8.8% N, 43.4% O, 5.1% B, and 0.9% P.

[0091] The X-ray electron spectrum analysis showed that the surface contained 6.3% amino group, 12.8% carboxyl group, 10.6% hydroxyl group and 4.8% boron hydroxyl group.

[0092] The transmission electron microscope analysis showed that the average particle size of the carbon nanospheres was 4.78 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com