Bismuth-based nanoparticle catalyst as well as preparation method and application thereof

A nanoparticle and catalyst technology, applied in the field of bismuth-based nanoparticle catalyst and its preparation, can solve problems such as direct utilization, complex components of reduction products, fracture, etc., and achieve the effects of mild conditions, good stability, and simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1). Preparation of bismuth metal-phenolic mesogen precursor:

[0051] Put 78.6 mg of ellagic acid and 205 mg of bismuth nitrate in a 30-ml clean glass bottle at room temperature, then slowly add 25 ml of N, methylpyrrolidone to the glass bottle, transfer the glass bottle to a dark environment, at room temperature ageing for 7 days. After the aging, the supernatant was removed, the obtained solid product was centrifuged at 10,000 rpm for 10 minutes, the excess supernatant was removed, and the sediment at the bottom was collected. After washing with 50 ml of N, methylpyrrolidone once, centrifugal collection, and finally washing with 50 ml of ethanol twice, then centrifugal collection, and vacuum drying treatment, the vacuum drying temperature is 50 ° C, and the vacuum drying time is 12 hours.

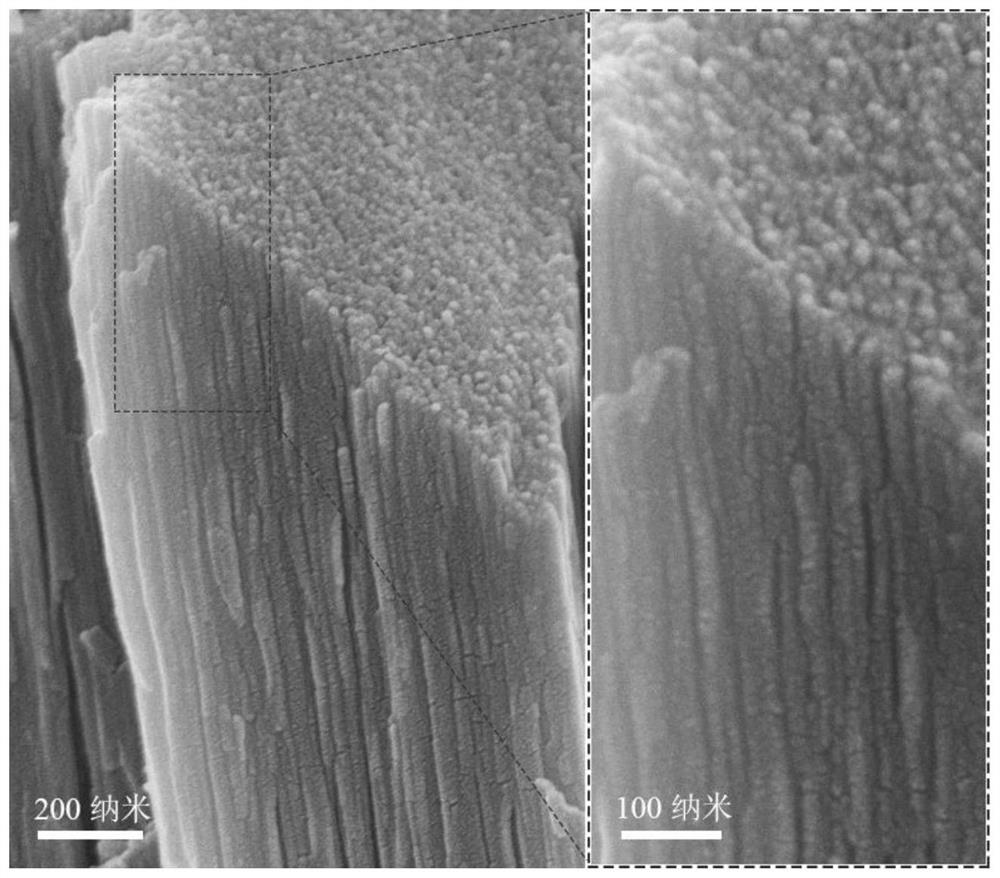

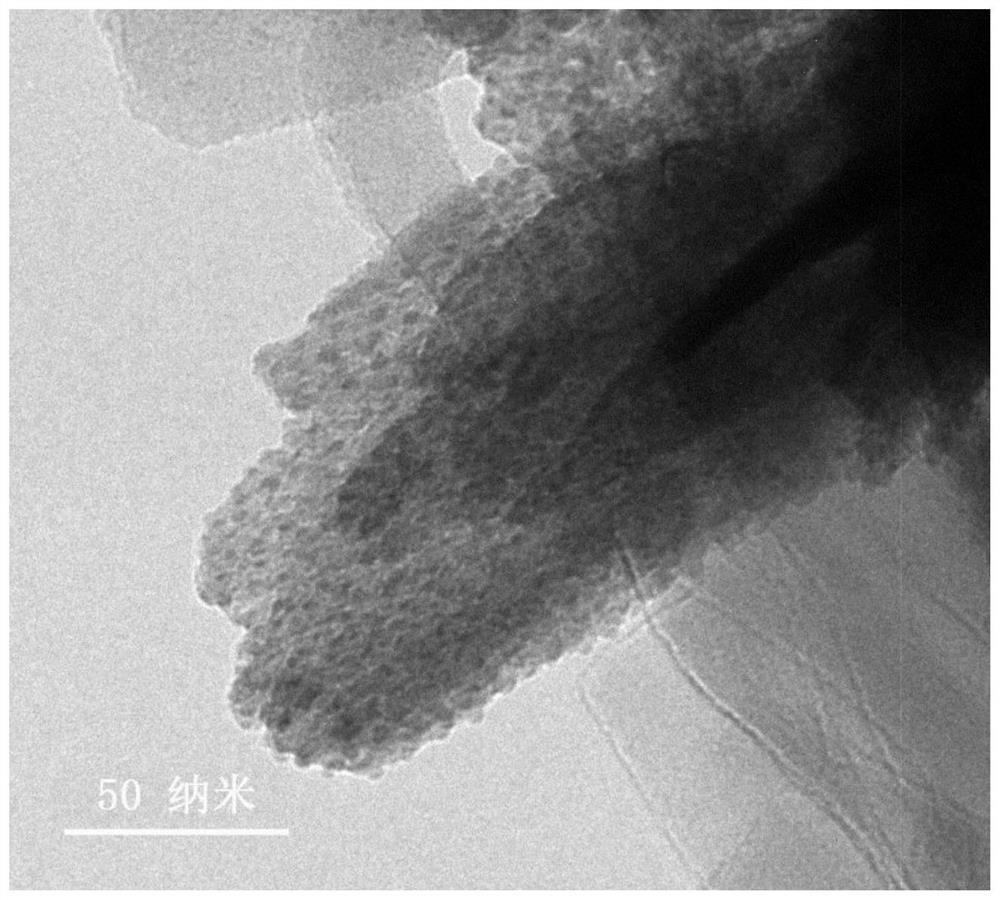

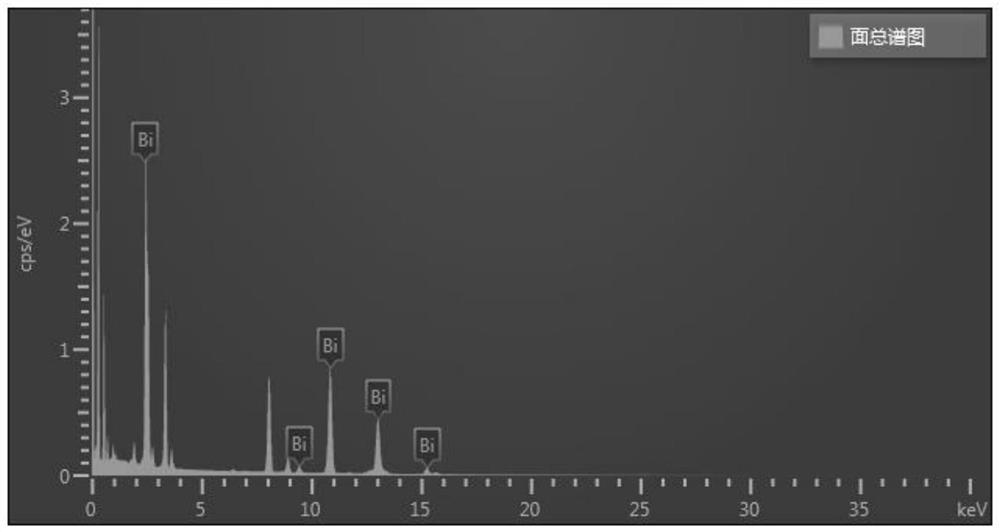

[0052](2) Electrochemical in situ formation of bismuth nanoparticles

[0053] At room temperature, 12 mg of bismuth metal-phenolic mesogen precursor was mixed with 10 μl of perf...

Embodiment 2

[0058] Catalytic performance testing of bismuth-based nanoparticle catalysts.

[0059] A bismuth-based nanoparticle catalyst prepared in Example 1 of the present invention was used to test the catalytic performance of the electroreduction reaction of carbon dioxide.

[0060] The bismuth carbon gas diffusion layer loaded with the bismuth-based nanoparticle catalyst obtained in Example 1 of the present invention was used as the working electrode, the nickel foam was used as the counter electrode, and the silver / silver chloride electrode was used as the reference electrode. Potassium solution was used as catholyte, and 1 mole per liter of potassium hydroxide solution was used as anolyte, and the carbon dioxide electroreduction performance test was carried out in a flow electrolytic cell. The carbon dioxide flow rate was maintained at 50 sccm and the electrolyte flow rate was maintained at 60 ml per minute during the test. The test adopts the constant current method, and the appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com