Preparation method of cross-linked organic-inorganic alkaline polyelectrolyte membrane

A polyelectrolyte and alkaline technology, which is applied in the field of preparation of organic-inorganic composite alkaline polyelectrolyte membrane, can solve the problem that the composite alkaline polyelectrolyte membrane needs to be improved, it is difficult to meet the needs of battery operation, and it cannot reflect alkali resistance, etc. problem, to achieve the effect of improving alkaline stability, low price, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 A preparation method of a cross-linked organic-inorganic composite alkaline polyelectrolyte membrane, the steps are as follows:

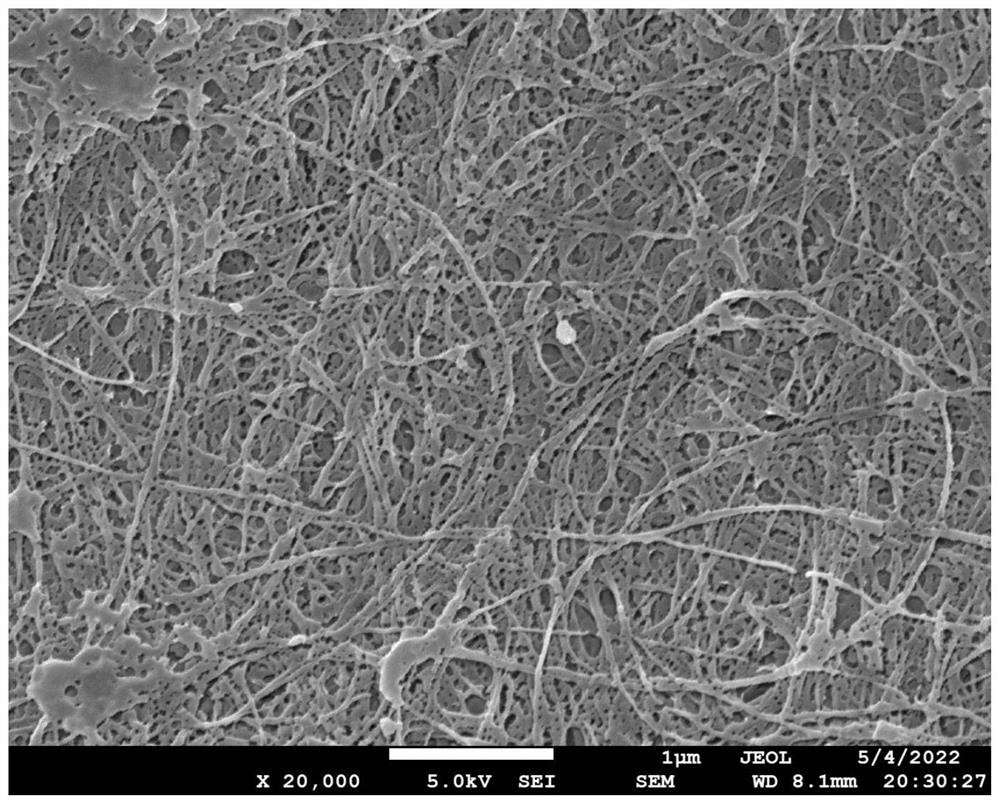

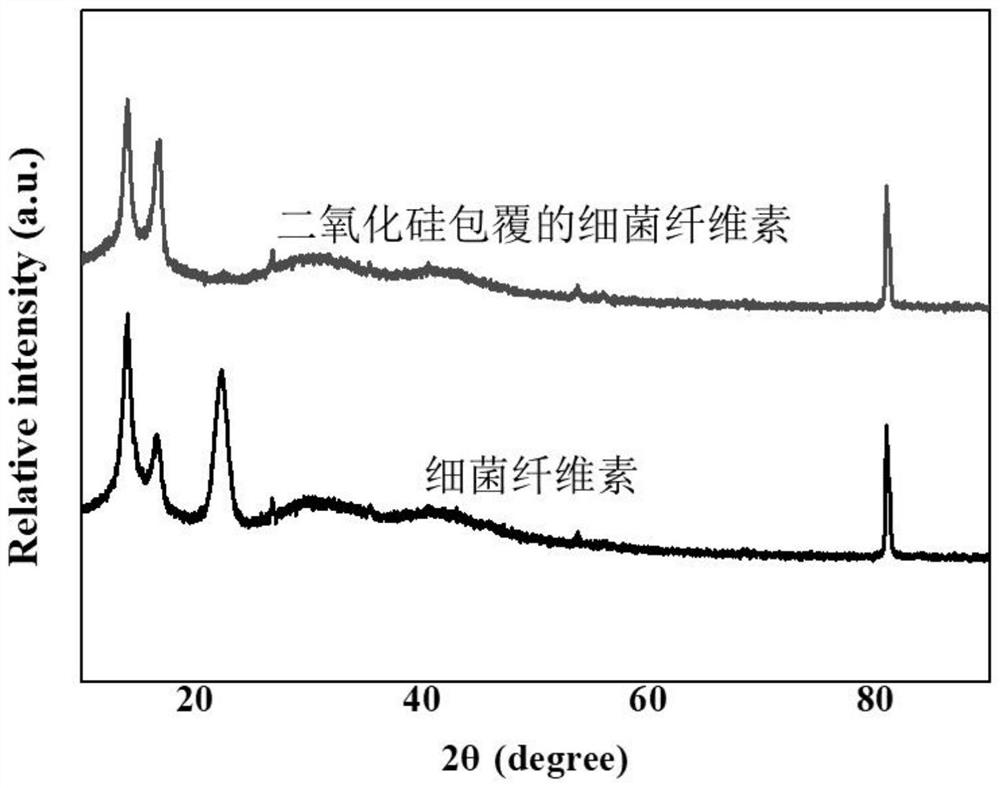

[0040] (1) Soak the commercial BC membrane in deionized water for 48h to fully absorb it, then heat it in a 0.1mol / L NaOH solution in a water bath at 90°C for 3h, then cool it to room temperature, and then reheat it. Repeatedly wash with a large amount of deionized water, and finally test the pH value of the film by gently pressing the surface of the film with pH test paper. When the pH value is neutral, a purified bacterial cellulose film is obtained. The scanning electron microscope image is shown in figure 1 ;

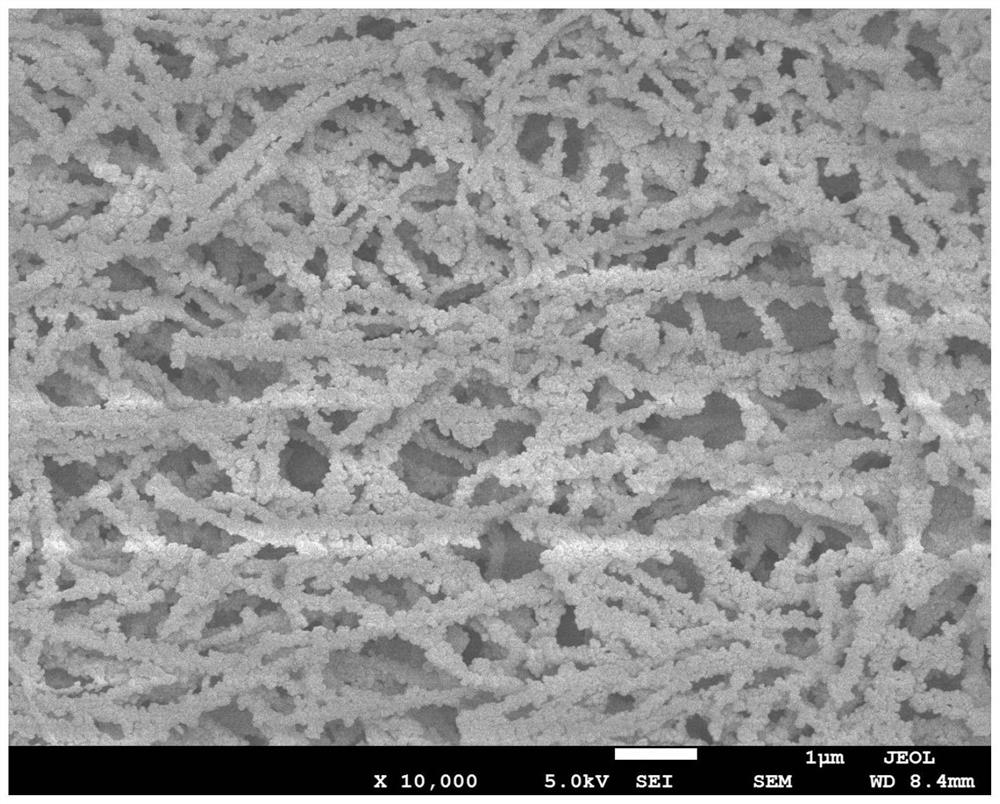

[0041] (2) Pour 90ml of tetraethyl orthosilicate solution into 400ml of absolute ethanol, stir and mix, add 2ml of 25wt% ammonia water, adjust the pH of the mixture to 8.5, and then add about 10×10cm of pure bacterial fiber membrane Put it into the mixed solution and let it stand at room temperature for 24 hours, then...

Embodiment 2

[0055] Embodiment 2 A preparation method of a cross-linked organic-inorganic composite alkaline polyelectrolyte membrane, the steps of which are as follows:

[0056] (1) Soak the commercialized BC membrane in deionized water for 32 hours to fully absorb it, and then heat it in a 0.2 mol / L NaOH solution in a water bath at 80 °C for 2.5 hours, and then cool it to room temperature. Then repeatedly wash with a large amount of deionized water, and finally use pH test paper to lightly press the surface of the membrane to test its pH value. When the pH value is neutral, a purified bacterial cellulose membrane is obtained;

[0057] (2) Pour 9ml of tetraethyl orthosilicate solution into 400ml of absolute ethanol, and add 2ml of ethanolamine. After stirring and mixing, put the pure bacterial fiber membrane of about 10 × 10 cm into the mixed solution and let it stand at room temperature for 20 hours. Quickly wash twice with absolute ethanol; pour 100ml of deionized water into 400ml of ab...

Embodiment 3

[0061] Embodiment 3 A preparation method of a cross-linked organic-inorganic composite alkaline polyelectrolyte membrane, the steps are as follows:

[0062](1) Soak the commercialized BC membrane in deionized water for 48 hours to fully absorb it, then heat it in a 0.5 mol / L NaOH solution in a water bath at 90 °C for 2 hours, then cool it to room temperature, and then reheat it. Repeatedly wash with a large amount of deionized water, and finally test the pH value of the membrane by gently pressing the surface of the membrane with pH test paper. When the pH value is neutral, a purified bacterial cellulose membrane is obtained;

[0063] (2) Pour 27ml of tetraethyl orthosilicate solution into 400ml of absolute ethanol, add 2ml of diethanolamine, stir and mix, and put about 10×10cm of pure bacterial fiber membrane into the mixed solution and let stand for 28h at room temperature, Quickly wash twice with absolute ethanol; pour 100 ml of deionized water into 400 ml of absolute ethan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com