Metal rubber composite board with high compression performance

A technology of metal rubber and composite board, applied in the direction of metal layered products, rubber layered products, applications, etc., can solve the problems of easy frosting of rubber materials, low performance of rubber gaskets, and low cohesive energy, so as to reduce the consumption , improve ozone resistance, improve the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

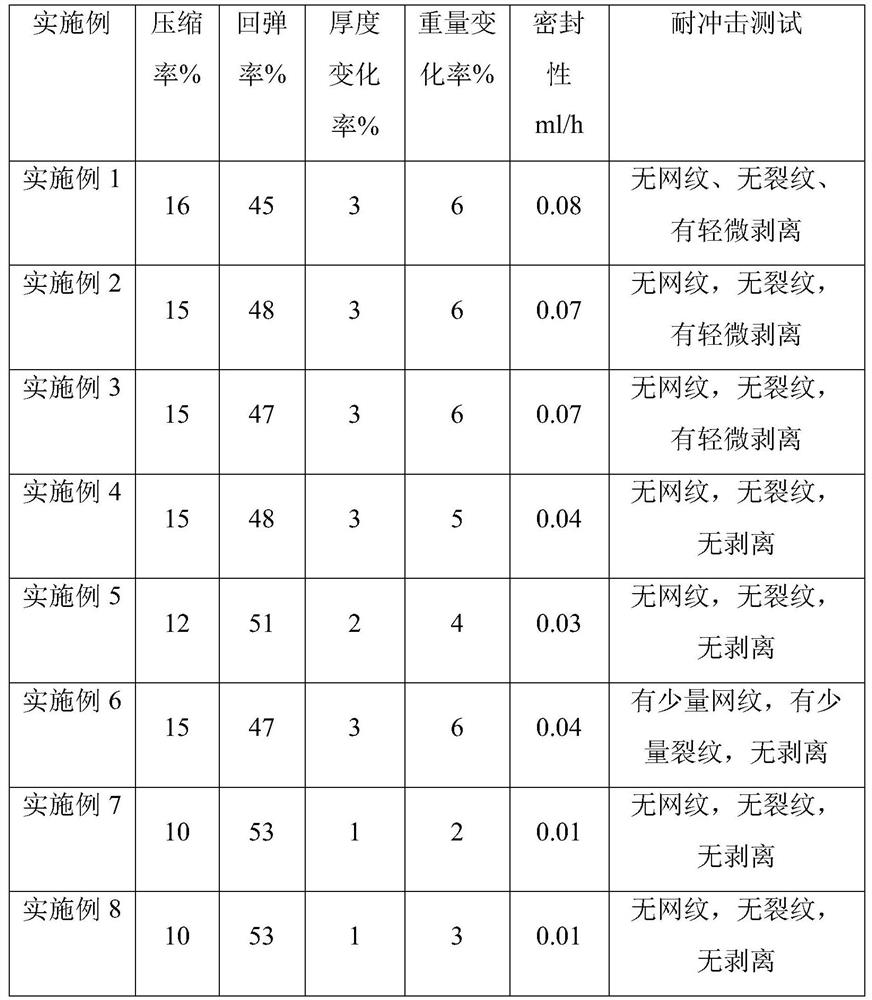

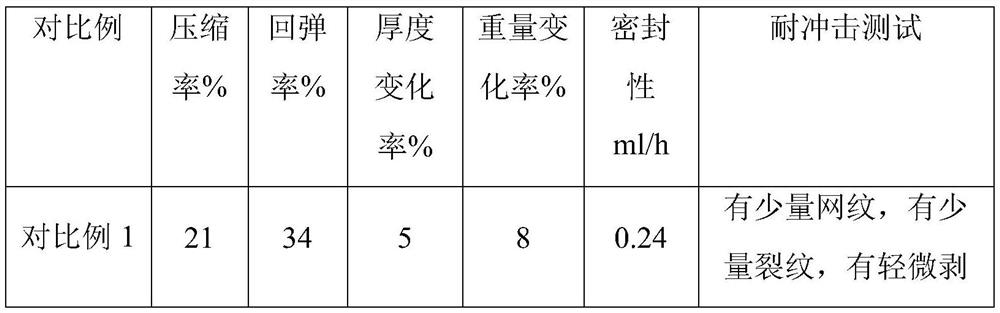

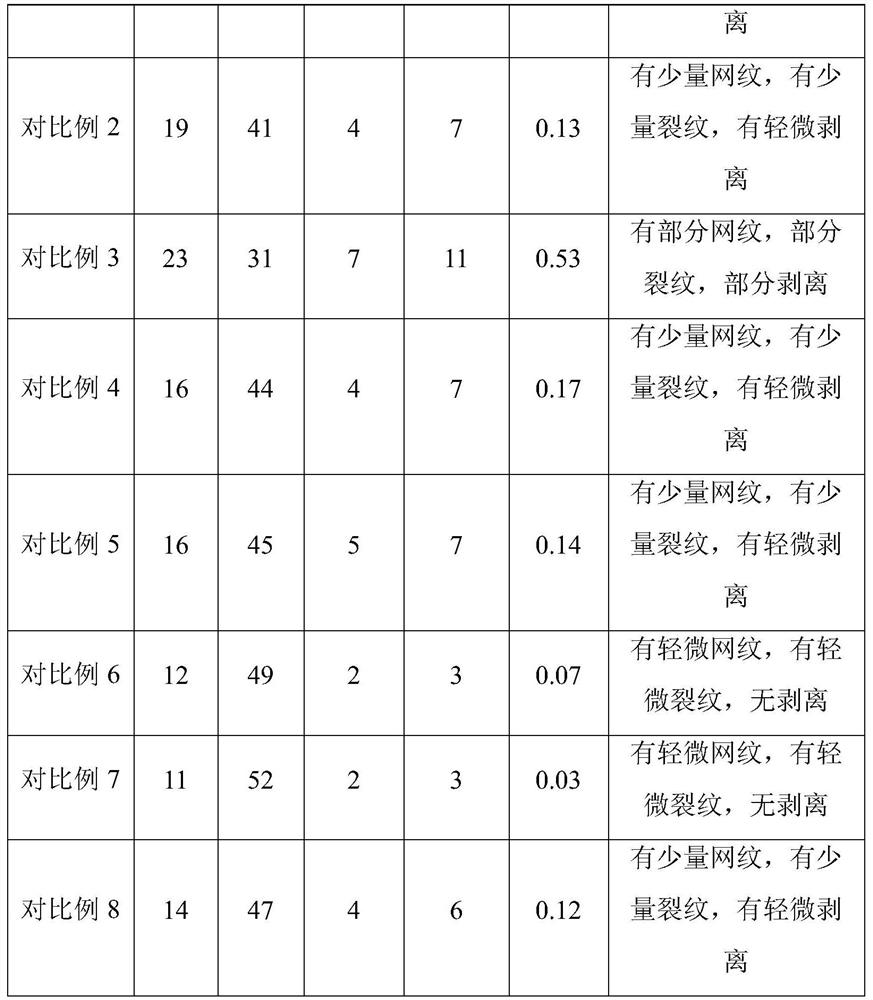

Examples

preparation example Construction

[0046] Preparation of starting materials and / or intermediates

[0047] Table 1 is the raw material and CAS number used in this application

[0048] raw material CAS number Stearic acid 57-11-4 Active Zinc Oxide 1314-13-2 carbon black 1333-86-4

[0049] The model selected for naphthenic oil is naphthenic oil N4006;

[0050] The model selected for carbon black is carbon black N660;

[0051] The grade selected for polylactic acid is REVODE190;

[0052] Silane coupling agent selects silane coupling agent KBM-403

[0053] The grade of organically modified montmorillonite is I.34TCN, and the bulk density is 250-300Kg / m 3 , the particle size is 14-18μm;

[0054] The model of EPDM raw rubber is EPDM4095, the ethylene content is 54wt.%, the Mooney viscosity ML(1+4) at 125°C is 59, and the third monomer ethylidene norbornene content is 8.1wt.%;

[0055] The model of the raw nitrile rubber is NBR3305E, and the Mooney viscosity ML(1+4) at 100°C is 55...

preparation example 1

[0056] Preparation example 1, the preparation of pretreatment EPDM raw rubber, comprises the following steps:

[0057] T1. Preparation of raw EPDM rubber;

[0058] T2. 1kg EPDM raw rubber, 0.2kg maleic anhydride and 0.05kg benzoyl peroxide in step T1 are sent into the twin-screw extruder and mixed uniformly, and the temperature is elevated to 180°C, and the reaction time is 10min, extruded, the extruded material is granulated by a granulator, and its particle size is 4(±1.5) mm;

[0059] T3. Vacuum-drying the raw EPDM rubber after granulation in step T2, the drying temperature is 75° C., and the drying time is 6 h to obtain the pretreated raw EPDM rubber.

Embodiment 1

[0062] A metal-rubber composite plate with high compression performance, comprising a metal base material and an EPDM rubber layer compounded on the upper and lower surfaces of the metal base material, wherein the material selected for the metal base material is a cold-rolled steel plate, and the thickness of the cold-rolled steel plate is is 1mm, and the thickness of the EPDM rubber layer used is 0.5mm.

[0063] The EPDM rubber layer consists of 60g pretreated EPDM raw rubber, 15g nitrile rubber raw rubber, 2g sulfur, 2.6g modified tackifying resin CKM-A, 1.3g p-tert-octylphenol formaldehyde resin, 0.145 g g antioxidant MMBZ, 0.054g antioxidant HS-911, 0.7g stearic acid, 0.2g active zinc oxide, 35g carbon black, 25g naphthenic oil, 2g organic modified montmorillonite, 2g accelerator EG-4 to make.

[0064] The preparation of a metal-rubber composite plate with high compressibility comprises the following steps:

[0065] S1. Preparation of raw materials;

[0066] S2. Surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com