Fluoride-free self-cleaning coating as well as preparation method and application thereof

A coating, selected technology, applied in coatings, chemical instruments and methods, conductive coatings, etc., can solve problems such as harsh experimental conditions, poor substrate adhesion, and difficulty in large-area application, and achieve excellent anti-corrosion performance and low cost. Low, the effect of preventing the adsorption of charged dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

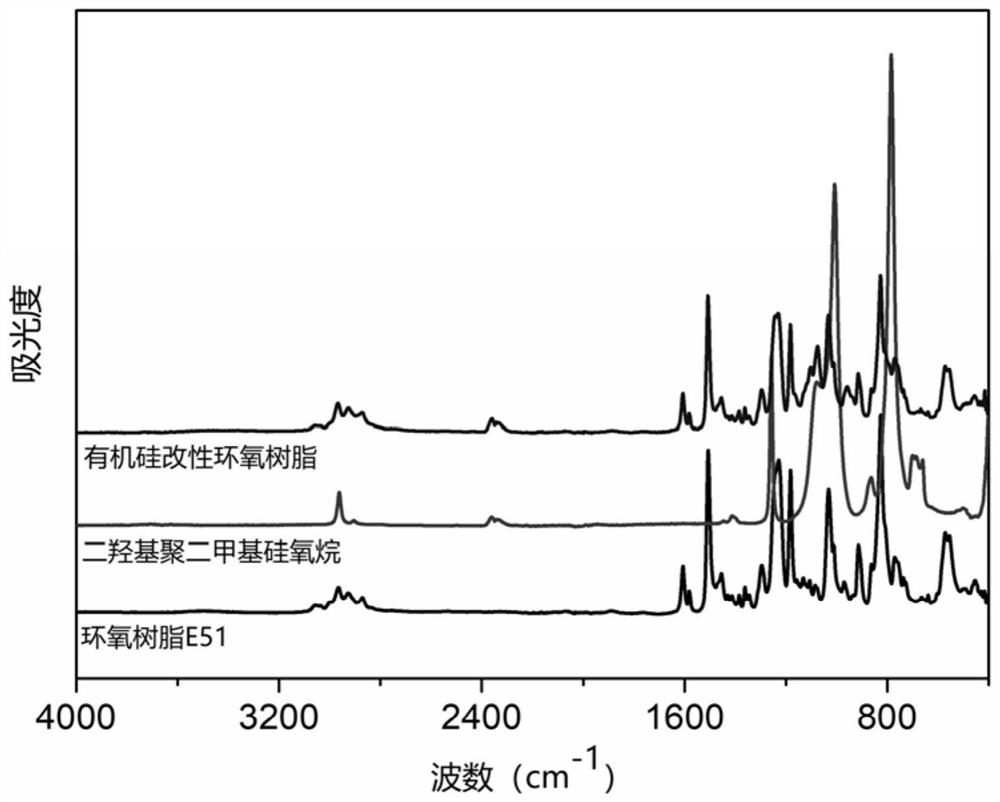

[0073] The preparation of organosilicon modified epoxy resin specifically includes: after fully mixing and reacting 50g epoxy resin and 12.5g 3-aminopropyltriethoxysilane, adding 20g dihydroxy polydimethylsiloxane, 2.5g dihydroxypolydimethylsiloxane, 2.5g Dibutyltin laurate, and stirring to obtain silicone-modified epoxy resin.

[0074] The epoxy value of the silicone-modified epoxy resin was 0.25 mol / 100 g. Its infrared spectrum is as figure 1 shown. from figure 1 It can be seen that the wave number is 785cm -1 , 862cm -1 and 1008cm -1 It is the characteristic absorption peak of dihydroxy polydimethylsiloxane. After the reaction between epoxy resin E51 and dihydroxy polydimethylsiloxane, the positions of these two peaks have shifted; the wave number is 913cm -1 It is the symmetric stretching vibration absorption peak of the epoxy group, and the characteristic absorption peak of this group still appears in the silicone-modified epoxy resin, indicating that the prepared s...

Embodiment 1

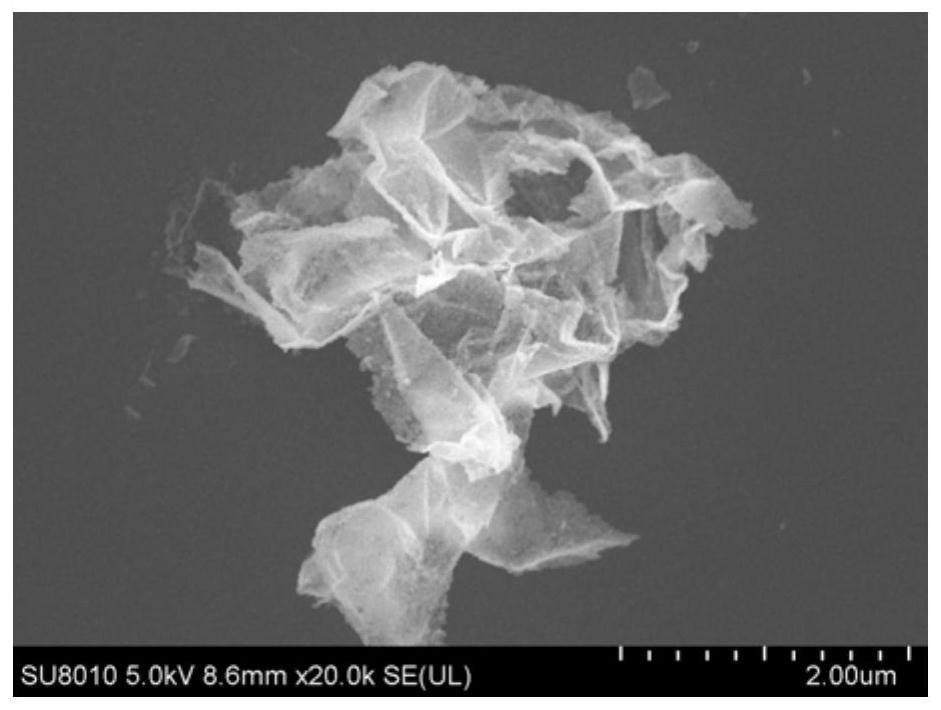

[0076] (1) Using absolute ethanol as a solvent, prepare 100 mL of a dispersion of 5 mg / mL graphene oxide, and circulate it for 3 times under a pressure of 30,000 PSI through a high-pressure microjet to obtain a dispersion of few-layer graphene oxide.

[0077] (2) adding the dispersion of the few-layer graphene oxide obtained in step (1) into the reaction flask, gradually adding 20 mL of deionized water under stirring, adding an appropriate amount of tetraethylammonium hydroxide to adjust the pH of the solution to 9, and finally 4.6 g of tetraethyl orthosilicate was added, and after stirring and reacting at room temperature for 5 hours, the silica-loaded graphene was obtained by centrifugation and solvent washing.

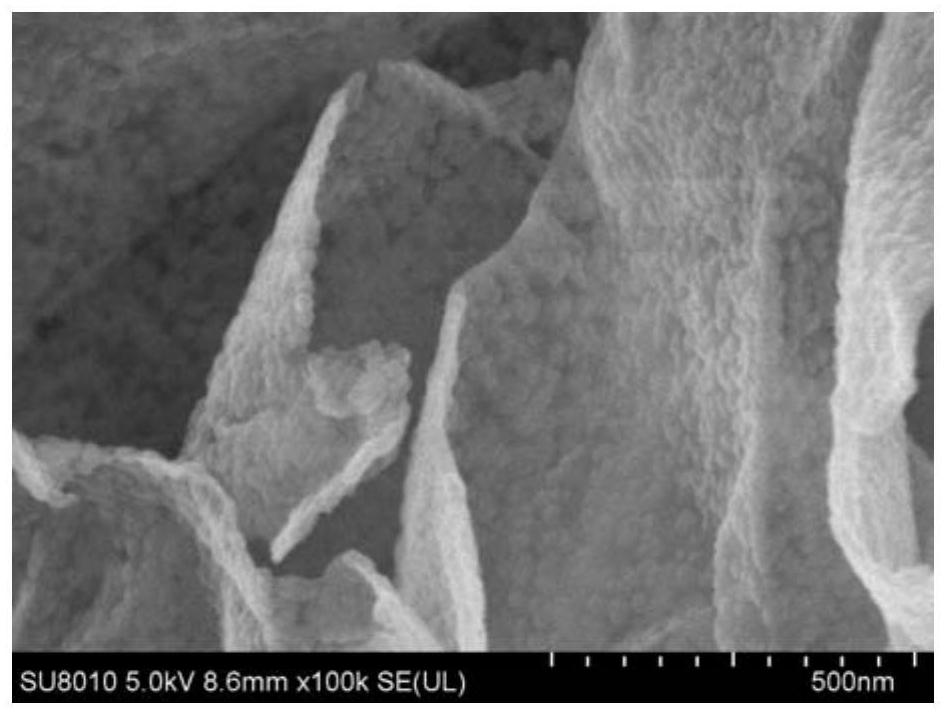

[0078] (3) Disperse 0.5 g of silicon dioxide-loaded graphene prepared in step (2) in ethanol, add 5 g of dimethyldichlorosilane under stirring, slowly add 5 mL of deionized water, and stir at 70° C. for 1 hour Then, the graphene loaded with modified silica is obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com