Silver-aluminum paste for P + surface of high-sheet-resistance TOPcon battery and preparation method of silver-aluminum paste

A high square resistance, silver-aluminum paste technology, applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of metal compound becoming smaller, contact failure, battery opening voltage gain, etc. problems, to achieve the effect of increasing sintering density, improving heat and activity, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

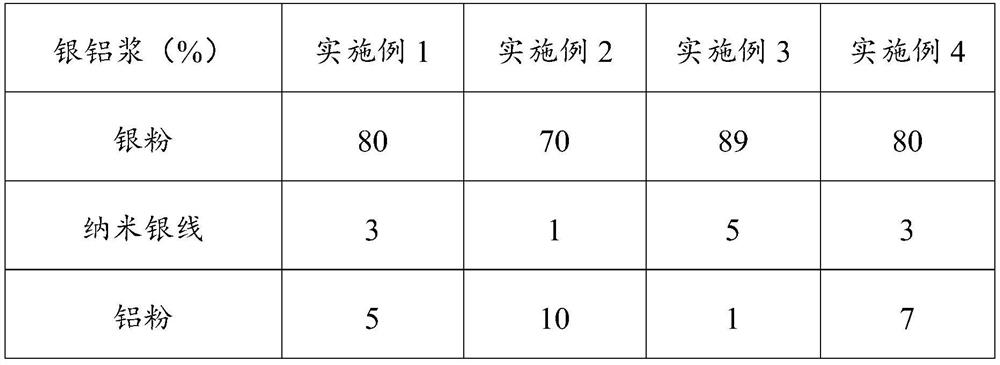

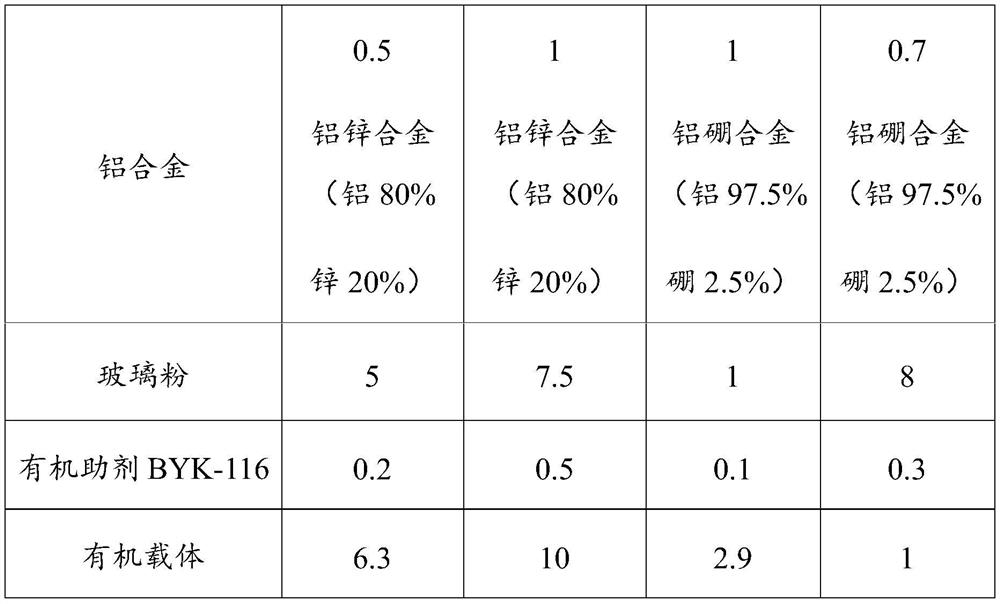

[0023] An embodiment of the silver-aluminum paste used for the P+ side of the high square resistance TOPcon battery according to the present invention, the formula of the glass powder in this embodiment is shown in Table 1, and the silver-aluminum paste used for the P+ side of the high square resistance TOPcon battery is shown in Table 1. The formula of the pulp is shown in Table 2.

[0024] In Example 1, the preparation method of the glass powder is as follows: according to the glass powder formula (weight percentage) in Table 1, batching is performed, (1) after the various components are fully mixed, the mixed materials are put into a crucible and placed in a crucible. Smelting in a high-temperature muffle furnace, the melting temperature is 1000 °C, and the holding time is 30 minutes; (2) Pour the heat-retained molten material into deionized water for quenching, and ball-mill and dry the water-quenched glass slag. That is to get glass powder.

[0025] The preparation metho...

Embodiment 2

[0029] The formula of the glass powder described in this example is shown in Table 1, and the formula of the silver-aluminum paste used for the P+ side of the high square resistance TOPcon battery is shown in Table 2.

[0030] The preparation method of the glass powder is the same as that of Example 1, and the preparation method of the silver-aluminum paste for the P+ side of the high square resistance TOPcon battery is the same as that of Example 1.

[0031] In this embodiment, the median diameter D of the silver powder 50 is 1.5um, and the bulk density is 3.4g / m 3 , the tap density is 5.54g / m 3 , the specific surface area is 1.0m 2 / g, the particle size of the nano-silver wire is 25nm, the length is 10-20μm, the median diameter of the aluminum powder is D 50 is 5um, and the bulk density is 0.52g / m 3 , the tap density is 0.86g / m 3 , the median diameter D of the aluminum-zinc alloy 50 is 3um, and the bulk density is 0.38g / m 3 , the tap density is 0.2g / m 3 .

Embodiment 3

[0033] The formulation of the glass powder described in this example is shown in Table 1, and the formulation of the silver-aluminum paste used for the P+ side of the high square resistance TOPcon battery is shown in Table 2.

[0034] The preparation method of the glass powder is the same as that of Example 1, and the preparation method of the silver-aluminum paste for the P+ side of the high square resistance TOPcon battery is the same as that of Example 1.

[0035] In this embodiment, the median diameter D of the silver powder 50 is 1.5um, and the bulk density is 3.4g / m 3 , the tap density is 5.54g / m 3 , the specific surface area is 1.0m 2 / g, the particle size of the nano-silver wire is 20nm, the length is 10-50μm, the median diameter of the aluminum powder is D 50 is 3.0um, and the bulk density is 0.48g / m 3 , the tap density is 0.75g / m 3 , the median diameter D of the aluminum-zinc alloy 50 is 3um, and the bulk density is 0.38g / m 3 , the tap density is 0.2g / m 3 . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median diameter | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com