Nickel-coated graphene and preparation method thereof

A graphene and nickel coating technology, which is applied in chemical instruments and methods, liquid chemical plating, coating, etc., can solve the problems of limited practical application fields, failure to meet the application requirements of conductive powder, and high cost of graphene. Achieve the effect of improving conductive shielding, reducing application cost and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] A second aspect of the present invention provides a method for preparing nickel-coated graphene, comprising the following steps:

[0058] S1. Surface treatment of graphene;

[0059] S2. adding nickel salt, complexing agent, carboxyl compound, stabilizer and accelerator into the reactor;

[0060] S3. the temperature of the reactor is heated up, and a carboxyl compound and a nickel salt solution are added;

[0061] S4. add the graphene treated in S1 in the reactor, add stabilizer, accelerator;

[0062] S5. adding the reducing agent to the reaction kettle, and stirring for 0.1-5h;

[0063] S6. The solution is filtered and dried to obtain nickel-coated graphene.

[0064] In one embodiment, the preparation method of the nickel-coated graphene includes the following steps:

[0065] S1. Rinse and filter graphene with inorganic acid and water;

[0066] S2. adding nickel salt, complexing agent, carboxyl compound, stabilizer and accelerator into the reactor;

[0067] S3. th...

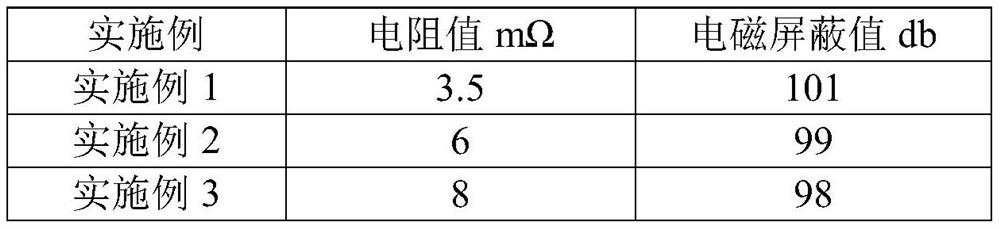

Embodiment 1

[0080] A nickel-coated graphene, in parts by weight, the raw material comprises the following components: 50 parts of graphene, 350 parts of nickel sulfate, 350 parts of potassium sodium tartrate, 30 parts of tartaric acid, 300 parts of citric acid, 15 parts of hydrazine hydrate, sulfur 20 parts of urea and 5 parts of sodium fluoride.

[0081] A preparation method of nickel-coated graphene, comprising the following steps:

[0082] S1. add 50 parts of reduced graphene oxide in the container, wash 30min with 20% hydrochloric acid 100ml with mass fraction, then filter with distilled water 500ml for 3 times to obtain graphene;

[0083] S2. 150 ml of nitric acid with a mass fraction of 5% was added to the graphene, and after standing for 30 minutes, the graphene was washed with distilled water, and the graphene was washed until neutral and filtered for use.

[0084] S3. add 15L of distilled water in the reactor, add 300 parts of nickel sulfate, 350 parts of potassium sodium tartra...

Embodiment 2

[0098] A nickel-coated graphene, in parts by weight, the raw material comprises the following components: 50 parts of graphene, 350 parts of nickel sulfate, 280 parts of potassium sodium tartrate, 30 parts of tartaric acid, 300 parts of citric acid, 15 parts of hydrazine hydrate, sulfur 20 parts of urea and 5 parts of sodium fluoride.

[0099] A preparation method of nickel-coated graphene, comprising the following steps:

[0100] S1. add 50 parts of reduced graphene oxide in the container, wash 30min with 20% hydrochloric acid 100ml with mass fraction, then filter with distilled water 500ml for 3 times to obtain graphene;

[0101] S2. 150 ml of nitric acid with a mass fraction of 7% was added to the graphene, and after standing for 30 minutes, the graphene was washed with distilled water, and then washed until neutral and filtered for use.

[0102] S3. add 15L distilled water in the reactor, add 300 parts of nickel sulfate, 280 parts of potassium sodium tartrate, 300 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com