Puncture-resistant and high-heat-insulation vacuum insulated panel and preparation method thereof

A vacuum insulation panel, puncture-resistant technology, applied in chemical instruments and methods, flat products, insulation improvement, etc., can solve problems such as poor ductility, penetration, and impact on the service life of vacuum insulation panels, and achieve increased rigidity and water resistance. abrasive properties, enhanced tensile strength and elongation at break, and excellent interfacial adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

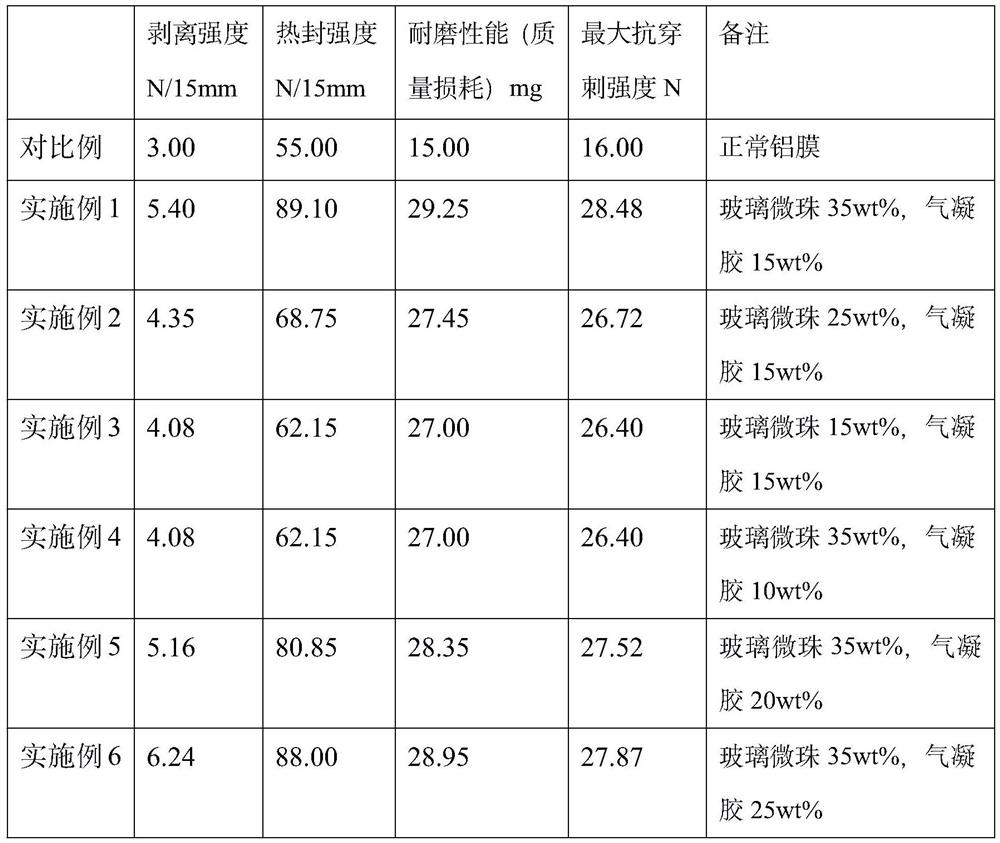

Embodiment 1

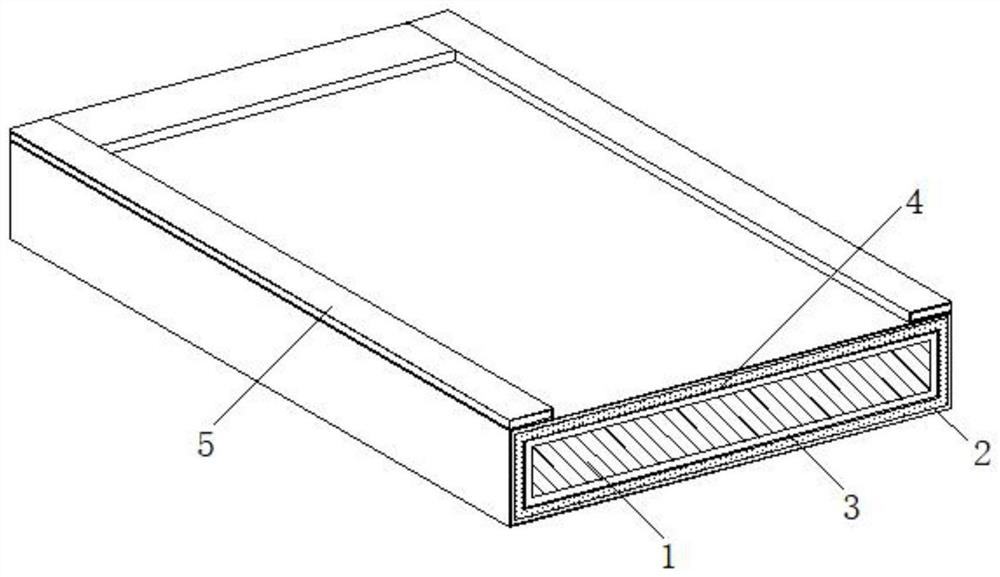

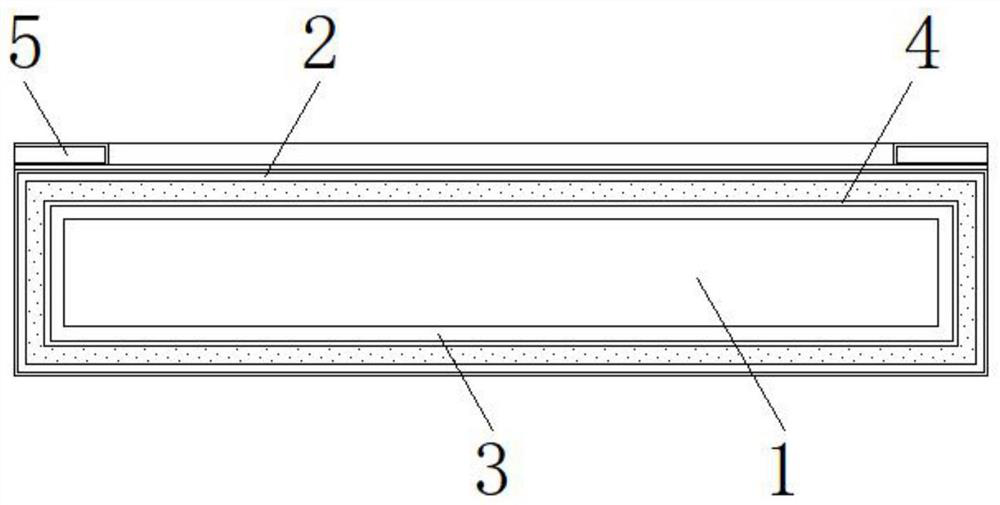

[0048] like figure 1 and 2 As shown, a puncture-resistant, high heat-insulating vacuum insulation panel of the present invention includes a VIP core material 1, a composite TPU barrier film and an aluminized film 3, and the VIP core material 1 is placed on the composite TPU barrier film and the aluminized film. In the sealed bag composed of 4, the composite TPU barrier film includes an aluminum film layer 3 and a modified TPU film 2 that is fully attached to it through glue, and the aluminum film layer 3 and the modified TPU film 2 form a modified TPU dry composite. Film, the modified TPU dry lamination film also includes a high thermal insulation coating applied to the outer surface of the modified TPU film, and the vacuum insulation panel also includes a composite TPU barrier film formed when the aluminum coating film is folded in the direction of 4 The folded structure 5.

[0049] The barrier film is a yin-yang film, one side of the yin-yang film is an aluminum film layer...

Embodiment 2

[0069] In this embodiment, the test steps are the same as those in Embodiment 1. The difference is as follows:

[0070] The silane coupling agent is hexamethylethylsilazane;

[0071] The aerogel content used is 18g

[0072] The total amount of mixed glass microbeads used in the thermal insulation coating is 30g;

[0073] The rest of the conditions remain unchanged.

Embodiment 3

[0075] In this embodiment, the test steps are the same as those in Embodiment 1. The difference is as follows:

[0076] The silane coupling agent is trimethylethoxysilane;

[0077] The aerogel content used is 15g

[0078] The total amount of mixed glass beads used in the thermal insulation coating is 15g;

[0079] The rest of the conditions remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com