Chlorine-free ammonia-free environment-friendly concrete antifreezing agent and preparation method thereof

An environmentally friendly concrete and antifreeze technology, applied in the field of concrete, can solve the problems of polluting the environment and producing ammonia gas, and achieve the effects of improving water retention and cohesion, not easy to burst, and outstanding antifreeze effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

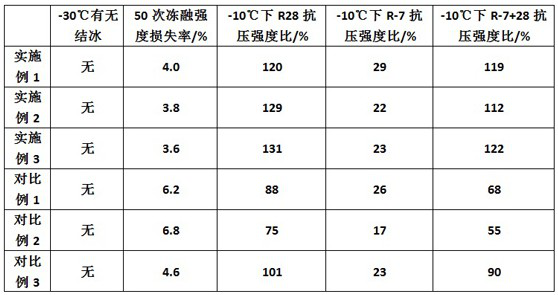

Examples

Embodiment 1

[0040] A chlorine-free, ammonia-free environment-friendly concrete antifreeze, comprising:

[0041] Early strength components: sodium thiocyanate, sodium carbonate, gypsum and calcium formate;

[0042] Plasticizing component: tributyl citrate;

[0043] Quick-setting component: glycerol;

[0044] Air-entraining components: sodium alkyl benzene sulfonate and porous sintered polyethylene particles;

[0045] Water-reducing components: sodium lignosulfonate and sodium polycarboxylate;

[0046] Coupling component: vinyltriethoxysilane.

[0047] Wherein, the weight ratio of sodium alkylbenzene sulfonate to porous sintered polyethylene particles is 5:1.

[0048] Finally, the parts by weight of each component are: 20 parts of early strength component, 15 parts of plasticizing component, 7 parts of quick-setting component, 4 parts of air-entraining component, 2 parts of water-reducing component and coupling component 2 servings.

[0049] The preparation method of the antifreeze co...

Embodiment 2

[0054] A chlorine-free, ammonia-free environment-friendly concrete antifreeze, comprising:

[0055] Early strength components: sodium thiocyanate, sodium carbonate, gypsum and calcium formate;

[0056] Plasticizing component: tributyl citrate;

[0057] Quick-setting component: glycerol;

[0058] Air-entraining components: fatty alcohol ether sodium sulfate and porous PC plastic particles;

[0059] Water-reducing components: sodium lignosulfonate and sodium polycarboxylate;

[0060] Coupling component: isobutyltriethoxysilane.

[0061] Wherein, the weight ratio of fatty alcohol ether sodium sulfate and PC plastic particles is 6.5:1.

[0062] Finally, the parts by weight of each component are: 22 parts of early strength components, 15 parts of plasticizing components, 8 parts of quick-setting components, 6 parts of air-entraining components, 3 parts of water-reducing components and coupling components 2 servings.

[0063] The preparation method of the antifreeze comprises th...

Embodiment 3

[0068] A chlorine-free, ammonia-free environment-friendly concrete antifreeze, comprising:

[0069] Early strength components: sodium thiocyanate, sodium carbonate, gypsum and calcium formate;

[0070] Plasticizing component: tributyl citrate;

[0071] Quick-setting component: glycerol;

[0072] Air-entraining components: fatty alcohol ether sodium sulfate and polyvinyl chloride foamed particles;

[0073] Water-reducing components: sodium lignosulfonate and sodium polycarboxylate;

[0074] Coupling component: isobutyltriethoxysilane.

[0075] Wherein, the weight ratio of fatty alcohol ether sodium sulfate and polyvinyl chloride foamed particles is 11:1.

[0076] Finally, the parts by weight of each component are: 25 parts of early strength components, 16 parts of plasticizing components, 8 parts of quick-setting components, 3 parts of air-entraining components, 3 parts of water-reducing components and coupling components 2 servings.

[0077] The preparation method of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com