Metal surface hardening method

A metal surface, rare earth compound technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of low density of infiltration layer, many hole defects, hardness and wear resistance of infiltration layer. Demand and other issues, to achieve the effect of high boron potential, improved infiltration ability, improved metal surface hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

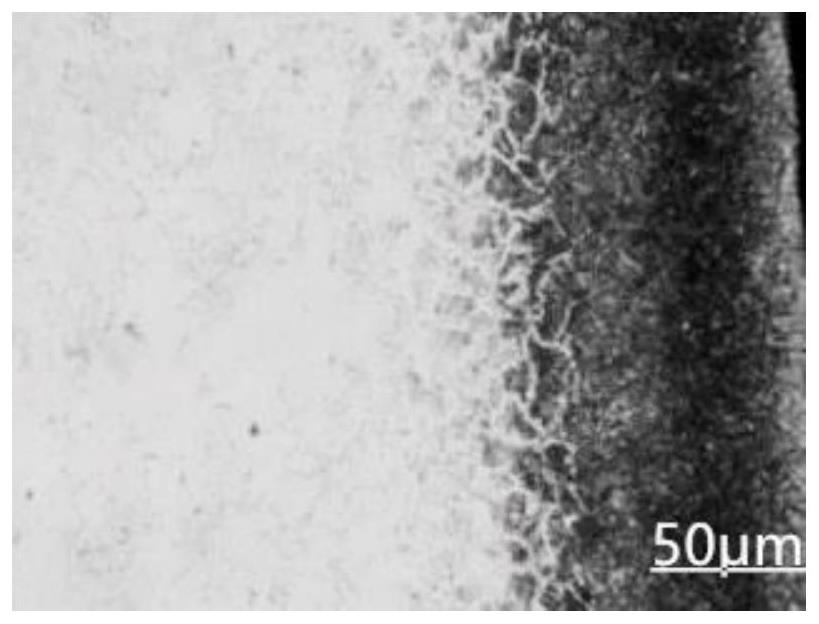

Image

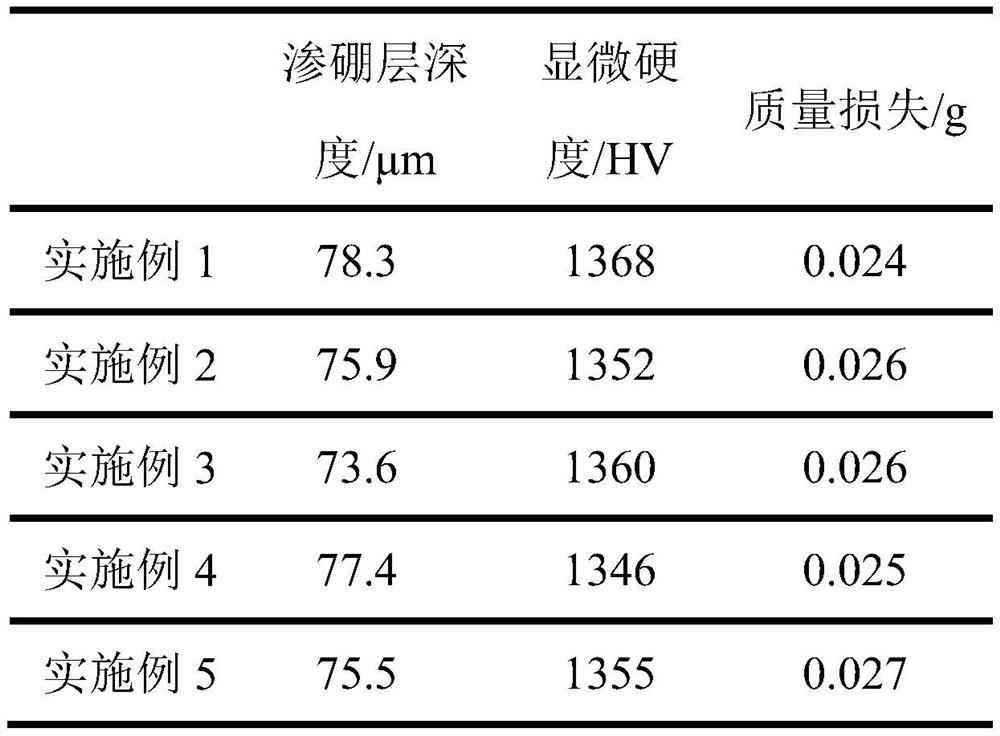

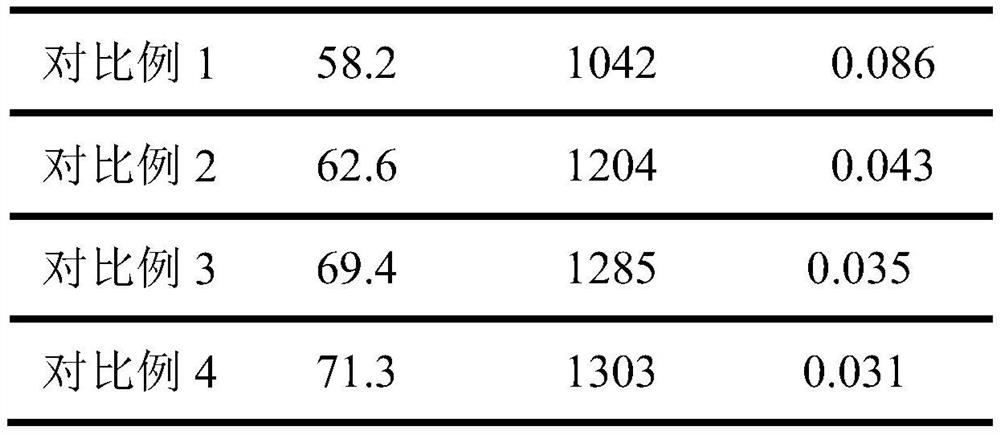

Examples

Embodiment 1

[0026] A metal surface hardening method:

[0027] 3000g of borax, 300g of boric acid, 400g of lanthanum oxide, 400g of lanthanum chloride, 100g of lanthanum aluminate, 2000g of silicon carbide and 3000g of graphite were vacuum-sealed in a closed tank, placed on a ball mill at room temperature for ball milling and powder mixing. The ratio is 50:1. After the ball milling is completed for 4 hours, 500 g of ammonium chloride and 650 g of sodium fluoride are added to the tank as infiltration agents, then vacuum-sealed, and placed on a ball mill to continue ball milling. After ball milling for 8 hours, the infiltration agent is obtained. 10wt% oxalic acid solution is used to clean the surface of TC4 titanium alloy to remove rust and oil, then wash and dry it for use, put the TC4 titanium alloy and the infiltrating agent into the graphite mold, bury the TC4 titanium alloy in the infiltrating agent, and seal the graphite mold. Put it into a resistance furnace for heating and impregnat...

Embodiment 2

[0031] A metal surface hardening method:

[0032] 3000g of borax, 500g of boric acid, 400g of lanthanum oxide, 400g of lanthanum chloride, 200g of lanthanum aluminate, 2000g of silicon carbide and 3000g of graphite were vacuum-sealed in a closed tank, placed on a ball mill at room temperature for ball milling and powder mixing. The ratio is 50:1. After the ball milling is completed for 4 hours, 500 g of ammonium chloride and 650 g of sodium fluoride are added to the tank as infiltration agents, then vacuum-sealed, and placed on a ball mill to continue ball milling. After ball milling for 8 hours, the infiltration agent is obtained. 10wt% oxalic acid solution is used to clean the surface of TC4 titanium alloy to remove rust and oil, then wash and dry it for use, put the TC4 titanium alloy and the infiltrating agent into the graphite mold, bury the TC4 titanium alloy in the infiltrating agent, and seal the graphite mold. Put it into a resistance furnace for heating and impregnat...

Embodiment 3

[0036] A metal surface hardening method:

[0037] 3000g of borax, 300g of boric acid, 400g of lanthanum oxide, 400g of lanthanum chloride, 200g of lanthanum aluminate, 2000g of silicon carbide and 3000g of graphite were vacuum-sealed in a closed tank, placed on a ball mill at room temperature for ball milling and powder mixing. The ratio is 50:1. After the ball milling is completed for 4 hours, 500 g of ammonium chloride and 650 g of sodium fluoride are added to the tank as infiltration agents, then vacuum-sealed, and placed on a ball mill to continue ball milling. After ball milling for 8 hours, the infiltration agent is obtained. 10wt% oxalic acid solution is used to clean the surface of TC4 titanium alloy to remove rust and oil, then wash and dry it for use, put the TC4 titanium alloy and the infiltrating agent into the graphite mold, bury the TC4 titanium alloy in the infiltrating agent, and seal the graphite mold. Put it into a resistance furnace for heating and impregnat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com