Preparation method of hard alloy drill tooth with high-entropy alloy coating

A technology of cemented carbide and high-entropy alloy, which is applied in metal material coating technology, coating, metal processing equipment, etc., can solve the problems of drill tooth failure and short service life, achieve excellent corrosion resistance and improve service life , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

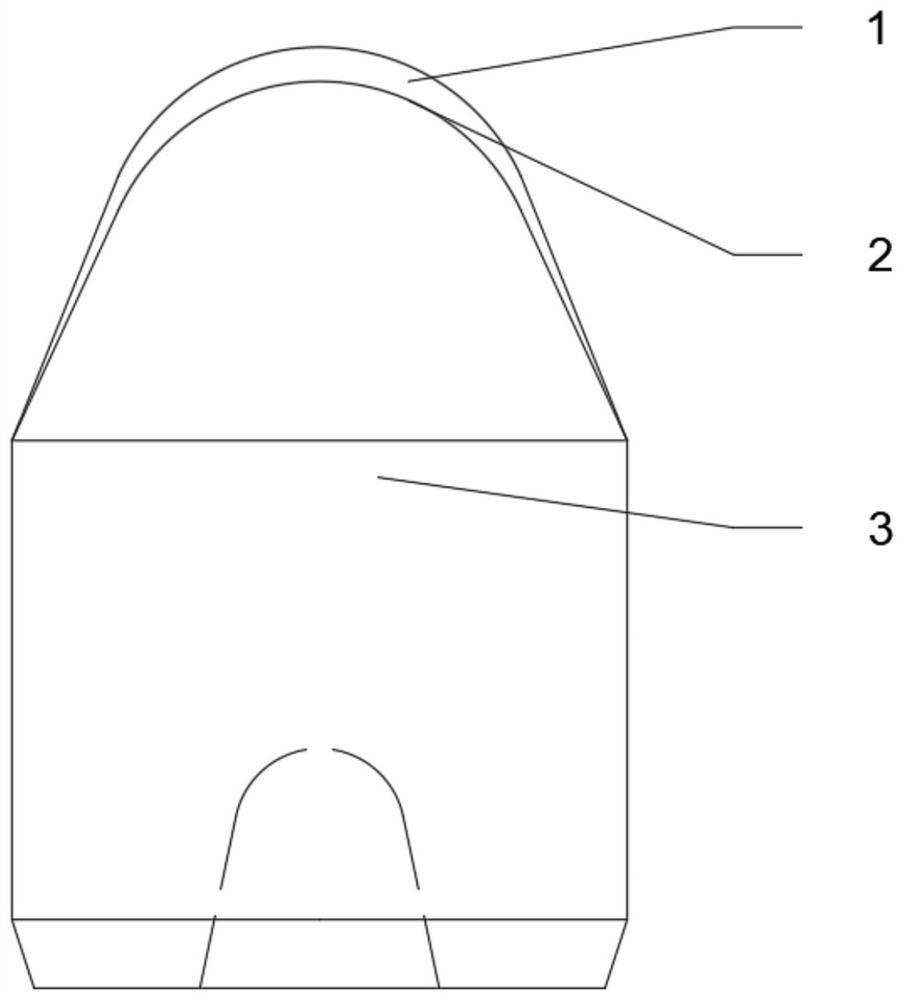

Image

Examples

Embodiment Construction

[0028] The preparation method of the cemented carbide drill tooth with the high-entropy alloy coating in the present embodiment includes the following steps:

[0029] Step A: processing the cemented carbide base into cemented carbide drill teeth; the cemented carbide base used in this embodiment is a tungsten carbide plate;

[0030] Step B: after grinding the to-be-clad surface of the cemented carbide drill teeth, use alcohol ultrasonic cleaning to remove oil stains for use; the grinding mesh of the to-be-clad surface of the cemented carbide drill teeth is 600 meshes;

[0031] Step C: Put Cr powder, Co powder, Ni powder, Fe powder, Nb powder, FeSi powder and FeCrC powder into a ball mill jar, add tungsten carbide WC grinding balls to the ball mill jar, and use a ball mill for ball milling at room temperature, The mass ratio of the high-entropy alloy coating powder and the tungsten carbide WC grinding ball is 5:1; the speed of the ball mill is 80r / min, and the ball milling time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com