Apple flavor yeast culture as well as preparation method and application thereof

A technology of yeast culture and aroma, which is applied in the field of fermentation, can solve the problems of increasing feed-to-meat ratio, strong wine taste, and affecting animal feed intake, etc., and achieve the effects of good food attractant, high number of viable bacteria, and increased daily weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

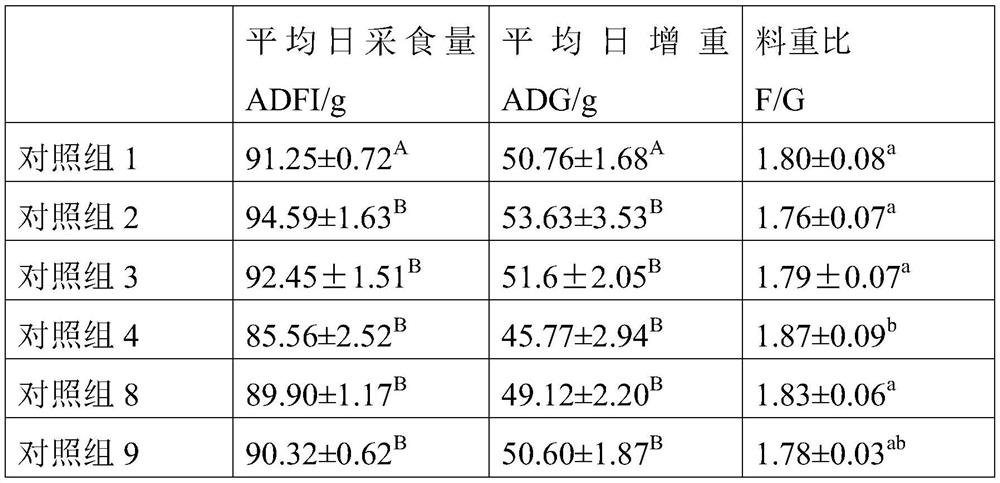

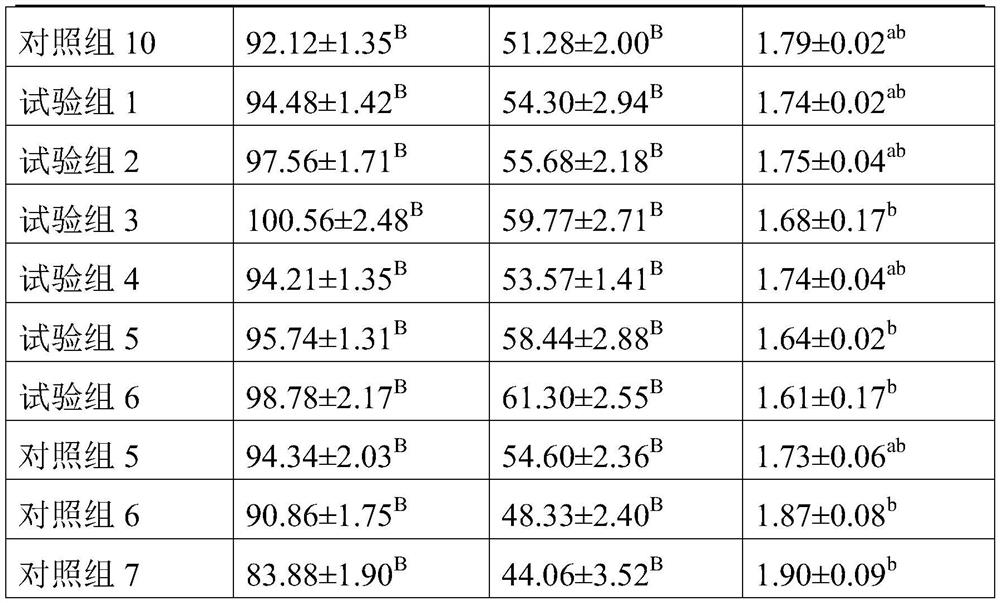

Examples

preparation example Construction

[0021] The present invention provides a preparation method for apple aroma yeast culture, including the following steps:

[0022] (1) Mix soybean meal and corn skin and shatter it as a base material;

[0023] (2) Preparation of Max Cruwin yeast fermentation liquid;

[0024] The preparation method is specifically: to inoculate the Max Cruwin yeast to the seed medium, cultivate 16h and 28 ° C for 16h to get the bottle seed liquid; The amount is 200L / min, the speed is 200rpm, and 40H is cultivated at 28 ° C. The Max Cruwin yeast fermentation liquid is obtained; Magotal Trinan Sugar and Trinan Hydraulic solution, add pH to 5.4, 115 ℃ sterilized 15min for later use after dissolving water;

[0025] (3) Supplement 20-30 % glyphtrole diet sugar hydrolysis liquid to Max Cruwin yeast fermentation liquid.

[0026] (4) The base material after vaccination is performed well for oxygen layer. The fermentation conditions are: the initial water control is 40-45 %, the pH is 5.0-6.0, the material t...

Embodiment 1

[0030] This embodiment provides an apple aroma yeast culture, which is prepared through the following methods:

[0031] (1) Mix 40 % soybean meal and 60 % corn skin and shatter it as a base material;

[0032] Mix 90 % palm kernel meal and 10 % melon soybean meal, use composite enzymes for enzymatic dismissal. The initial pH value of enzymatic disinvices is 6.0, water is 75 %, the temperature is 60 ° C, the enzymatic disintegration time is 8 hours, after the enzymatic dismissal Perform the plate frame filtering to obtain a glycolic diets with a solid content of 15 %, as a carbon source for reinforcement; Internal cutting polytanase, 2 % β-polytanase, 0.5 % pectinase, the remaining amount is malt paste;

[0033] (2) Preparation of seed medium and fermentation medium: 2 % isotin, 1 % of yeast powder, and 20 % glycogen, oligosaccharigosaccharide hydrolysis, and adjust the pH to 5.4, 115 ℃ sterilized 15min spare;

[0034] Take 50ml seeds to cultivate a 500ml triangle bottle, and inocul...

Embodiment 2

[0039] This embodiment provides an apple aroma yeast culture, which is prepared through the following methods:

[0040] (1) Mix 40 % soybean meal and 60 % corn skin and shatter it as a base material;

[0041] Mix 90 % palm kernel meal and 10 % melon soybean meal, use composite enzymes for enzymatic dismissal. The initial pH value of enzymatic disinvices is 5.0, water is 70 %, the temperature is 50 ° C, the enzymatic disintegration time is 6 hours, after the enzymatic dismissal Perform the plate frame filtering to obtain a glycolic dietary tatrogether with a solid content of 15 %, as a carbon source for spare; Internal cutting polytanase, 1 % β-polytanase, 0.1 % pectinase, the remaining amount is malt paste;

[0042] (2) Preparation of seed medium and fermentation medium: 2 % isotin, 1 % of yeast powder, and 10 % glycal diet sugar hydrolysis liquid with water dissolving pH to 5.4, 115 ℃ sterilized 15min for later use;

[0043] Take 100ml seeds to cultivate a 500ml triangle bottle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com