Benzopyrene-containing wastewater treatment system and method

A treatment system, benzopyrene technology, applied in the field of benzopyrene-containing wastewater treatment system, can solve the problems of incomplete adsorption/desorption, frequent regeneration, low catalyst efficiency, etc., achieve small footprint, high-efficiency treatment, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

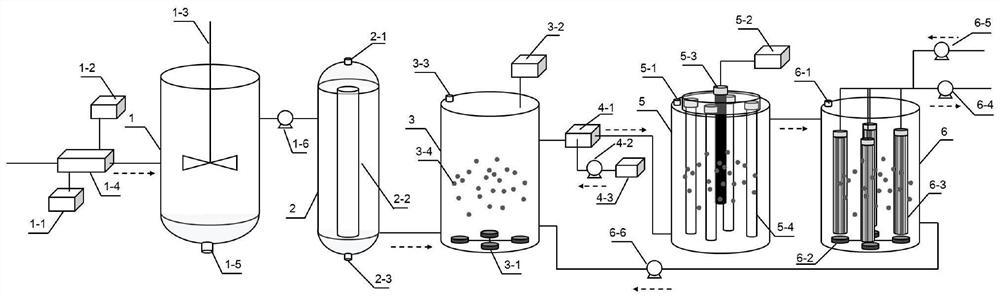

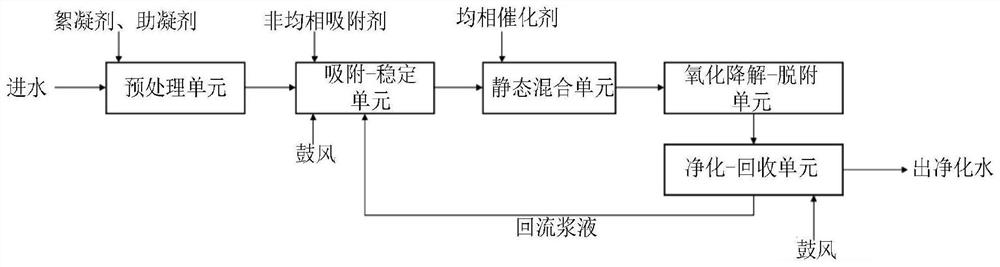

Image

Examples

Embodiment 1

[0168] The benzopyrene-containing wastewater to be treated is taken from the cold coke water of a coking plant in a refinery. Its COD is 1327 mg / L, the BOD is 290 mg / L, and the concentration of benzopyrene is 162.9 μg / L.

[0169] The wastewater containing benzopyrene to be treated enters the coagulation reaction tank, and the flocculant polyaluminum chloride 200mg / L, the coagulation aid anionic PAM 5mg / L, the residence time in the coagulation reaction tank is 0.5h, and the stirring time is 10min / h, the stirring speed is 30r / min, the filter element is made of PP cotton, the pore size is 1μm, and the adsorption-stabilization cell body is loaded with TiO 2 The OMS-2 molecular sieve (prepared by reflux roasting, trade name RUC-2) is used as a heterogeneous adsorbent, based on the total weight of the heterogeneous adsorbent, TiO 2 The load is 3% by weight, the particle size is 100 μm, and the dosage is 1.0 g / L. Hydrogen peroxide is used as a homogeneous catalyst in the first stati...

Embodiment 2

[0172] The wastewater containing benzopyrene to be treated was taken from the coking wastewater of a coking plant, and its COD was 861 mg / L, the BOD was 162.6 mg / L, and the concentration of benzopyrene was 84.3 μg / L.

[0173] The wastewater containing benzopyrene to be treated enters the coagulation reaction tank, and the flocculant polyaluminum chloride 100mg / L and the coagulant anionic PAM 6mg / L are added respectively. The residence time in the coagulation reaction tank is 0.625h, and the stirring time is 10min. / h, the stirring speed is 30r / min, the filter element is made of PP cotton, the pore size is 5μm, and the adsorption / stabilization cell body is loaded with TiO 2 OMS-2 molecular sieve as heterogeneous adsorbent, TiO 2 The loading amount is 3% by weight, the particle size is 100 μm, and the dosage is 1.0 g / L. In the first static mixer, sodium persulfate is used as a homogeneous catalyst, and the molar concentration ratio of the homogeneous catalyst to the benzopyrene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com