Modified polyphenol amine material as well as preparation method and application thereof

A polyphenolic amine modification technology, applied in the field of modified polyphenolic amine materials and preparation, can solve the problems of poor acid and alkali resistance, poor water solubility resistance, etc., and achieve good acid and alkali resistance, good lipophilicity, and water solubility resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

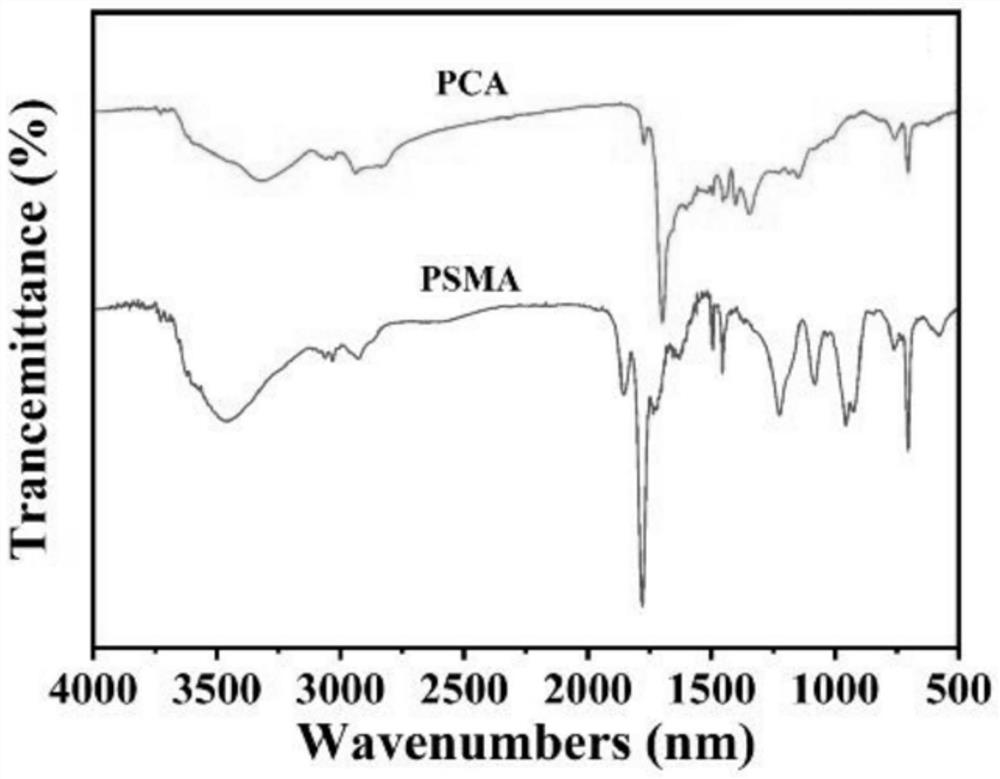

[0025] In a first aspect, the present invention provides a method for preparing a modified polyphenolamine material, comprising the following steps:

[0026] The amine source and the phenol source are reacted to generate polyphenolamine;

[0027] Adding low molecular weight polystyrene-maleic anhydride to polyphenolamine to carry out imidization reaction;

[0028] The phenol source is added to the imidization reaction product, the Michael addition reaction is carried out with the free amine group, and then the amine source is added to extend the molecular chain to obtain the product;

[0029] The product is washed, separated, and freeze-dried by using an alkaline aqueous solution, to obtain the final product;

[0030] The amine source is diamine or polyamine; the phenol source is diphenol or polyphenol.

[0031] In some embodiments, the amine source is selected from one of ethylenediamine, butanediamine, hexamethylenediamine, phenylenediamine, polyethyleneimine, diethylenetr...

Embodiment 1

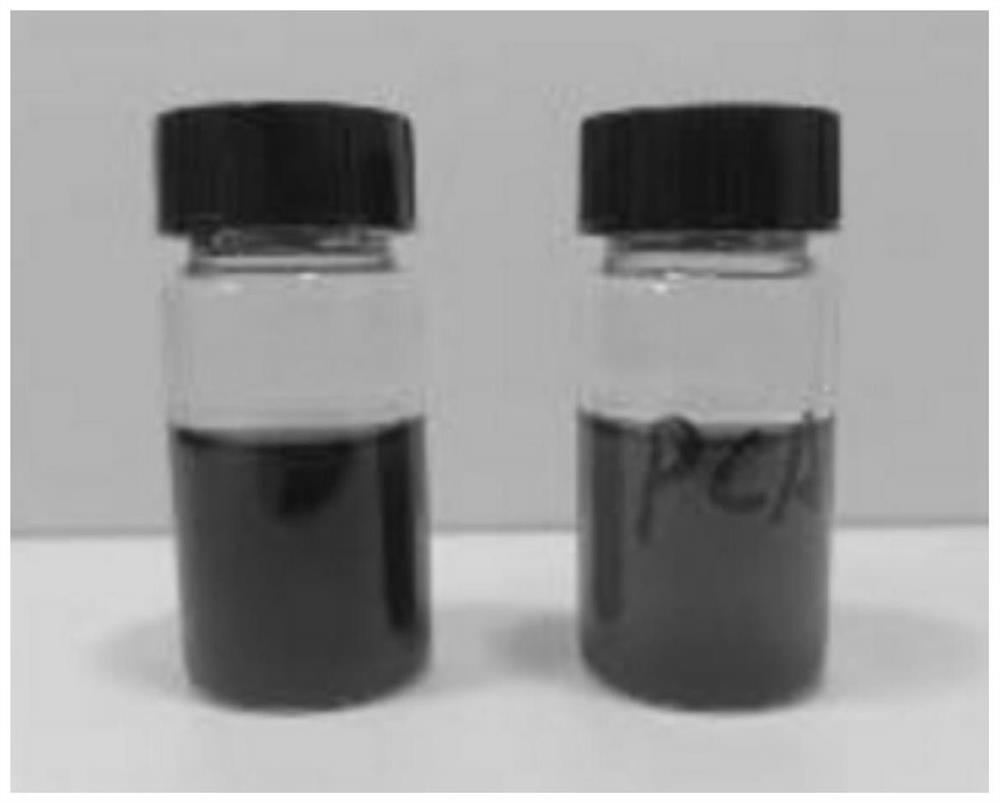

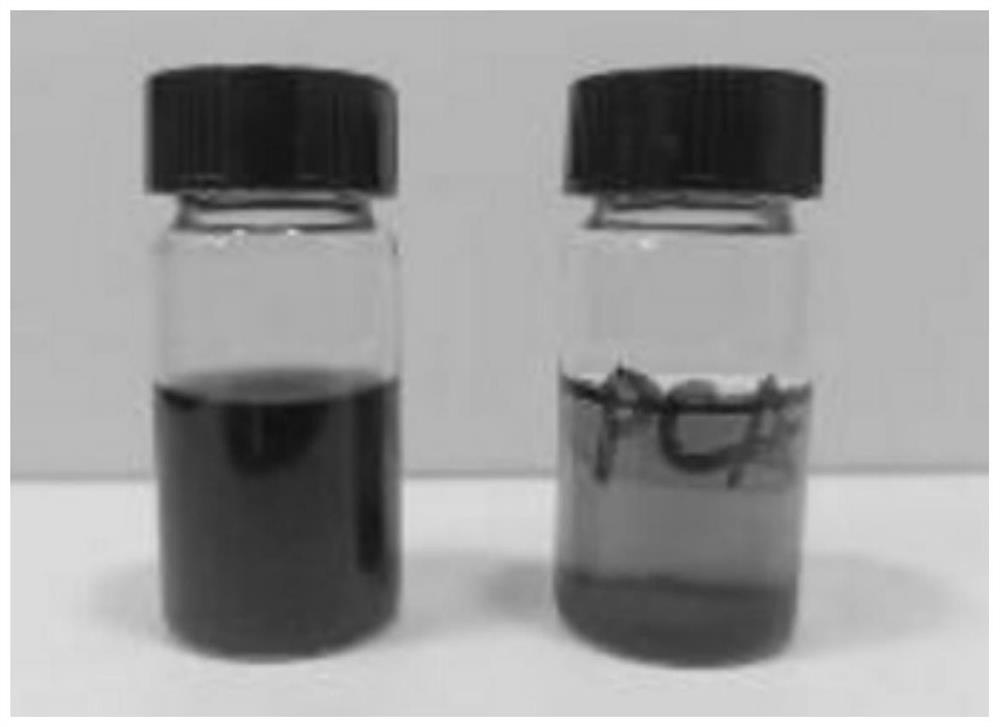

[0041] Weigh 1.26 g of tetraethylene pentamine and dissolve it in an appropriate amount of ultrapure water and place it on a magnetic stirrer to stir evenly, adjust the pH to 10 with NaOH, then weigh 0.22 g of catechol and dissolve it in water to prepare a solution, and then mix The catechol solution was added to the tetraethylene pentamine solution and continued to stir to react for 12 hours to form a polyphenolamine mixed solution, then weigh 0.67g of polystyrene-maleic anhydride and add it to the polyphenolamine mixed solution to disperse it uniformly. After homogenization, the mixed solution was transferred to a hydrothermal reactor to obtain polyphenolamine containing styrene-maleimide and polystyrene-maleimide through imidization reaction at 160° C. for 6 h. Transfer the mixed solution after the imidization reaction to a beaker and continue to stir for 12h, then add 0.66g of catechol and continue to stir for 24h, and then add 1.134g of tetraethylenepentamine to continue t...

Embodiment 2

[0047]Weigh 1.26 g of tetraethylene pentamine and dissolve it in an appropriate amount of ultrapure water and place it on a magnetic stirrer to stir evenly, adjust the pH to 10 with NaOH, then weigh 0.22 g of catechol and dissolve it in water to prepare a solution, and then mix The catechol solution was added to the tetraethylene pentamine solution and continued to stir to react for 12 hours to form a polyphenolamine mixed solution, then weigh 0.67g of polystyrene-maleic anhydride and add it to the polyphenolamine mixed solution to disperse it uniformly. After homogenization, the mixed solution was transferred to a hydrothermal reactor to obtain polyphenolamine containing styrene-maleimide and polystyrene-maleimide through imidization reaction at 160° C. for 6 h. Transfer the mixed solution after the imidization reaction to a beaker and continue to stir for 12h, then add 1.1g of catechol and continue to stir for 24h, and then add 2.52g of tetraethylenepentamine to continue the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com