Stable and medium-yield oxidant for oil production and preparation method of stable and medium-yield oxidant

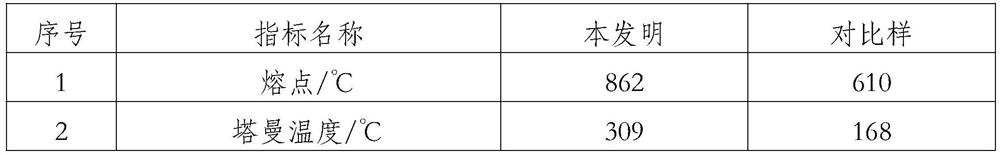

A technology of oxidant and stabilizer, which is applied in the field of stable and medium-yield oxidant for oil production and its preparation. It can solve the problems of long generation time, inability to control the purity of oxidant, and long storage time of finished products, and achieve the effect of stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The invention provides a stable and medium-yield oxidant for oil production, which comprises, in parts by weight: 3 parts of potassium permanganate, 20 parts of 0.5mol / L potassium hydrogen persulfate aqueous solution, 5 parts of sodium chlorate, 2- 10 parts of iodobenzoic acid, 3 parts of ammonium chloride, 1 part of potassium chloride, 1 part of sodium bisulfate, 10 parts of ammonium peroxodisulfate, 3-(2,3-glycidoxy)propyltrimethoxysilane 100 parts of DMF, 1 part of 3% sodium bicarbonate aqueous solution, and 200 parts of pure water.

[0042] In addition, the present invention also provides a method for preparing a stable and medium-yield oxidant for oil production, which is characterized by comprising the following preparation steps:

[0043] ⑴ Miscibility preparation:

[0044] Potassium permanganate was added to the reactor, N 2 The temperature was raised to 60°C under the protection, and 30% potassium hydrogen persulfate aqueous solution was slowly added dropwise...

Embodiment 2

[0064] The invention provides a stable and medium-yield oxidant for oil production, which is characterized in that, in parts by weight, it comprises: 6 parts of potassium permanganate, 30 parts of 0.5mol / L potassium hydrogen persulfate aqueous solution, 8 parts of sodium chlorate parts, 15 parts of 2-iodobenzoic acid, 5 parts of ammonium chloride, 2 parts of potassium chloride, 2 parts of sodium hydrogen sulfate, 15 parts of ammonium peroxodisulfate, 3-(2,3-glycidoxy)propyltrimethyl 5 parts of oxysilane, 120 parts of DMF, 5 parts of 3% sodium bicarbonate aqueous solution, and 200 parts of pure water.

[0065] In addition, the present invention also provides a method for preparing a stable and medium-yield oxidant for oil production, comprising the following preparation steps:

[0066] ⑴ Miscibility preparation:

[0067] Potassium permanganate was added to the reactor, N 2 The temperature was raised to 70°C under the protection, and 30% potassium hydrogen persulfate aqueous s...

Embodiment 3

[0087] The invention provides a stable and medium-yield oxidant for oil production, which comprises, in parts by weight: 5 parts of potassium permanganate, 25 parts of 0.5mol / L potassium hydrogen persulfate aqueous solution, 6 parts of sodium chlorate, 2- 12 parts of iodobenzoic acid, 4 parts of ammonium chloride, 2 parts of potassium chloride, 2 parts of sodium bisulfate, 13 parts of ammonium peroxodisulfate, 4 parts of 3-(2,3-glycidoxy)propyltrimethoxysilane parts, 110 parts of DMF, 3 parts of 3% aqueous sodium bicarbonate solution, and 200 parts of pure water.

[0088] In addition, the present invention also provides a method for preparing a stable and medium-yield oxidant for oil production, comprising the following preparation steps:

[0089] ⑴ Miscibility preparation:

[0090] Potassium permanganate was added to the reactor, N 2 The temperature was raised to 65°C under protection, and 30% potassium hydrogen persulfate aqueous solution was slowly added dropwise to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com