Method for preparing high-rate lithium battery negative electrode material from natural graphite spherical tailings

A natural graphite, spherical technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of poor rate performance of natural graphite spherical tailings, and achieve the effect of improving rate performance, alleviating anisotropy, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

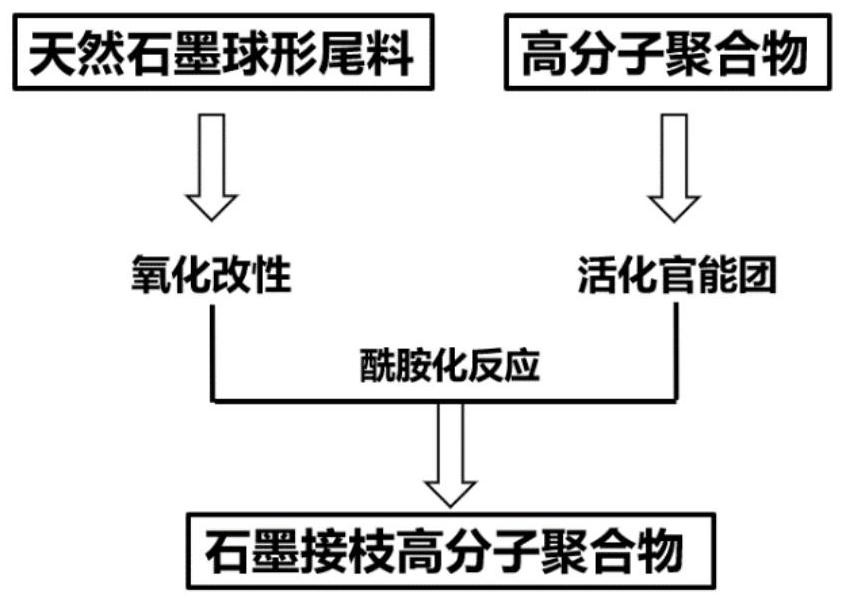

Method used

Image

Examples

Embodiment 1

[0020] The purified natural graphite spherical tailings were placed in a beaker, a certain amount of 30% H2O2 solution was added, and the solid-liquid ratio of graphite to H2O2 solution was 1:50 to form a suspension, which was stirred at room temperature for 4 hours, and the reacted suspension was The turbid liquid was washed with a large amount of deionized water, filtered with suction and dried to obtain product 1. A certain amount of product 1 was mixed with organic solvent DMF, the solid-liquid ratio of graphite and DMF was 1:00, the catalyst NHS and EDC were added after ultrasonic dispersion for 30 minutes, the mass ratio of graphite and catalyst was 1:3, stirred at room temperature for 30 minutes, and then added The PEA solution with a molecular weight of 2000, the solid-liquid ratio of graphite to PEA is 1:6, and stirred at room temperature for 6 hours. The reacted product was washed with a large amount of DMF, centrifuged, filtered with suction and dried to obtain the ...

Embodiment 2

[0023] Put a certain mass of natural graphite spherical tailings after purification, sulfuric acid (concentration of 98.8wt.%) with a mass fraction of 5% of the graphite tailings and 30% H2O2 in a beaker to form a mixture, and use deionized water according to the solid-liquid ratio of 1. : 150 to a constant volume, after forming a suspension, stir at room temperature for 4 hours, rinse the reacted suspension with a large amount of deionized water, suction filtration and dry to obtain product 1. A certain amount of product 1 is mixed with organic solvent ethanol, the solid-liquid ratio of graphite and ethanol is 1:100, the catalyst HOBt is added after ultrasonic dispersion for 30min, the mass ratio of graphite and catalyst is 1:3, stirred at room temperature for 30min, and then added with a molecular weight of 2000 mPEG-NH2 solution, the solid-liquid ratio of graphite and mPEG-NH2 is 1:6, and stirred at room temperature for 6h. The reacted product was washed with a large amount...

Embodiment 3

[0026]Put a certain mass of natural graphite spherical tailings after purification and potassium permanganate solid powder with a mass fraction of 20% of the graphite tailings in a beaker to form a mixture, and use deionized water to make a solid-liquid ratio of 1:50 to form a suspension. The solution was stirred at room temperature for 8 h, the reacted suspension was washed with a large amount of deionized water, filtered and dried to obtain product 1. A certain amount of product 1 was mixed with organic solvent acetonitrile, the solid-liquid ratio of graphite and acetonitrile was 1:150, the catalyst DCC was added after ultrasonic dispersion for 30min, the mass ratio of graphite and catalyst was 1:2, stirred at room temperature for 30min, and then polyethylene was added. The solid-liquid ratio of imine, graphite and polyethyleneimine was 1:4, and the mixture was stirred at room temperature for 12 h. The reacted product was washed with a large amount of acetonitrile, centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com