Preparation method and application of modified charcoal adsorbent

A biochar, adsorbent technology, applied in the fields of biofuels, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of secondary pollution and high production costs, and achieve improved adsorption capacity, low cost, improved adsorption and fixation capacity and The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

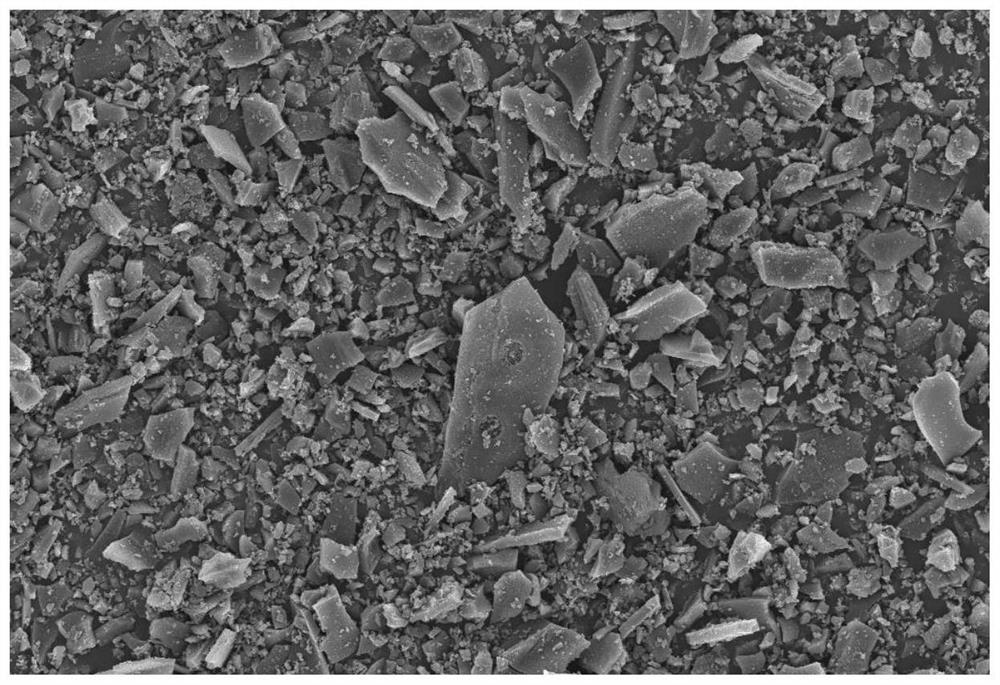

[0043] The preparation method of a modified biological carbon attachment provided by the present invention includes the following steps:

[0044] S1. Wash, dry, and grind biological charcoal;

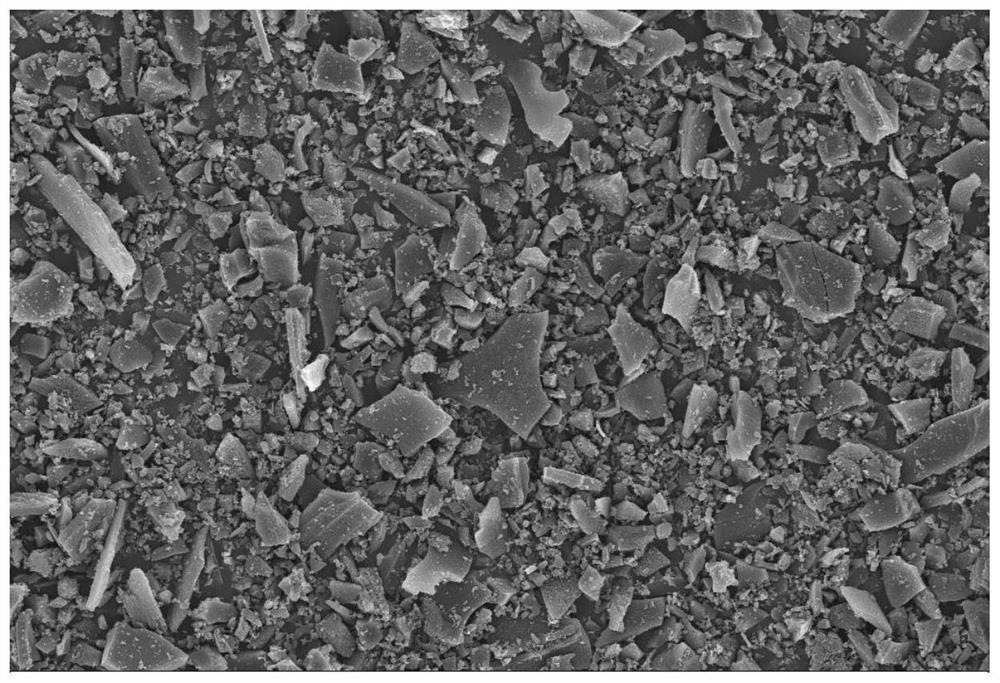

[0045] S2, after taking the ball and grinding biochemical, add alkaline solution and heated back; separate liquid separation to obtain alkaline activated activated carbon;

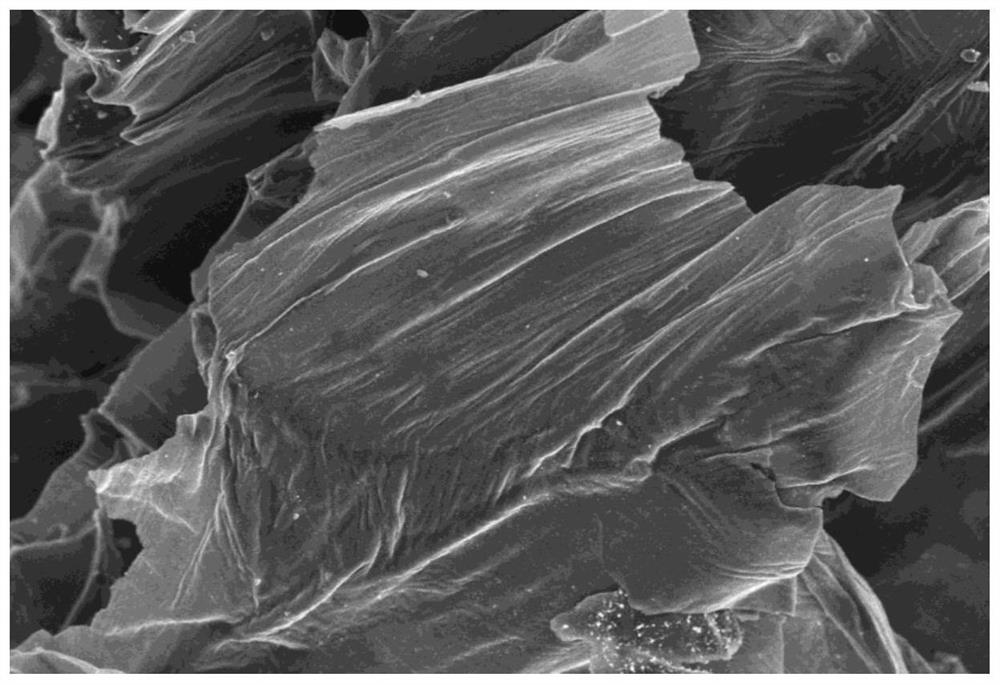

[0046] S3. Put the alkali activated biochand on the temperature control electrical board and place it under ultraviolet light;

[0047] S4, the irradiation end stops heating, cooled to room temperature, and obtained modified biological charcoal. In a preferred embodiment, the biological charcoal used is minerals (coal), plants (branches, leaves, fruits, straws) and organic waste (sludge, algae) as raw materials, and are prepared by low temperature and heat cracking technology; Specific preparation process: Broken the raw materials of biochand carbon, wash the dust with ion water, and dry it at 100 ° C. Then, put the bio...

Embodiment 1

[0062] This embodiment provides a preparation method for modified biological carbon suction agents. The specific process is as follows:

[0063] S1, take 500g coal -made biological charcoal, the proportion of volume L to the mass KG is washed through the unit of ion water. , Place it in a 60 ° C oven, dry 12h;

[0064] Put the dry biological charcoal for 30 minutes on the ball at 300R / min; after 80 destination sieves;

[0065] S2. Take 100 g of the sieved biological charcoal powder, add 5mol / L KOH solution 1L, and return to 4h at 80 ° C, cool to room temperature, wash, remove ion water washing until washing the liquid neutral, 60 ° C oven bake Dry until constant.

[0066] S3. Put the dry biological charcoal in the glass cultivation utensils after drying, and the thickness is about 3mm. Put it vertically under the ultraviolet light and put the glass dish on the temperature control electrical board. The temperature of the electric board is 200 ℃; Keep the distance between the glass ...

Embodiment 2

[0069] This embodiment provides a preparation method for modified biological carbon suction agents. The specific process is as follows:

[0070] S1, take 500g wooden biochand, wash it after the ionic water (after washing the liquid is colorless), place it in a 60 ° C oven, dry 12h, and need to use it; 30 minutes; then 80 destination sieves;

[0071] S2. Take 100g of biological charcoal powder after the sieve, add 5mol / L KOH solution 1L, and return to 4h at 80 ° C, cool to room temperature, filter, remove ion water washing until washing the liquid neutral, 60 ℃ oven, Dry to the constant weight;

[0072] S3. Put the dry biological charcoal in the glass cultivation utensils after drying, and the thickness is about 3mm. Put it vertically under the ultraviolet light and put the glass dish on the temperature control electrical board. The temperature of the electric board is 200 ℃; Keep the distance between the glass and ultraviolet lamps of the glass and ultraviolet light; adjust the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com