Preparation method of organic acid molybdenum oil-soluble catalyst for slurry reactor hydrogenation

An organic acid and catalyst technology, applied in the field of hydrocracking catalyst preparation, can solve the problems of difficult utilization and handling, low dispersion, easy deactivation, etc., and achieve the effect of good oil solubility, uniform dispersion and reasonable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a method for preparing an organic acid molybdenum oil-soluble catalyst for slurry bed hydrogenation, and the method for preparing the organic acid molybdenum oil-soluble catalyst comprises:

[0026] (1) adding the short carbon chain organic acid and the molybdenum source catalyst into the flask according to the molar ratio of 3~5:1, and adding the solvent of the preset molar ratio to react to obtain the short carbon chain organic acid reaction system, wherein the reaction temperature is 50~95℃, and the reaction time is 1~5h;

[0027] (2) According to the molar ratio of the long carbon chain organic acid and the short carbon chain organic acid being 1:1~5, the long carbon chain organic acid is added dropwise to the prepared short carbon chain organic acid reaction system dropwise , wherein, the dripping rate is 1~5ml / min, the reaction temperature of the dripping process is 50~95 ℃, and the temperature is raised to 180~250 ℃ after the drippi...

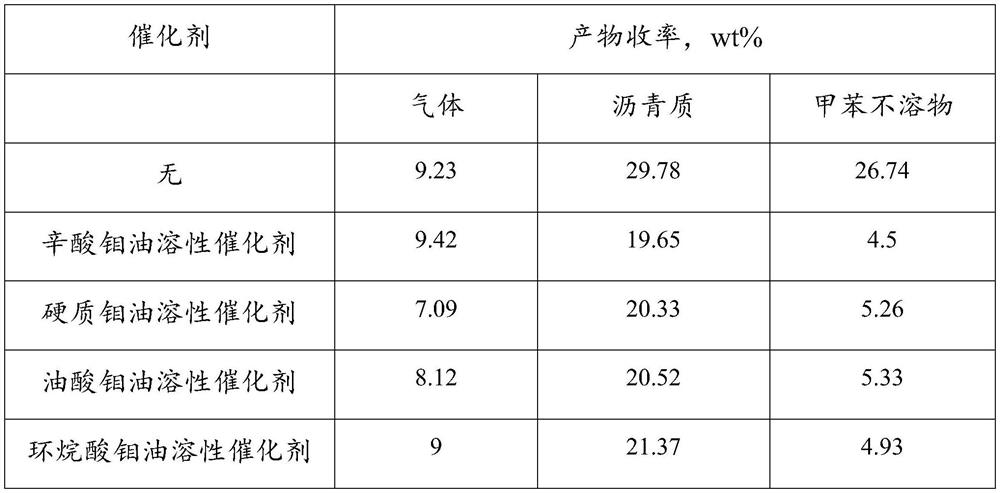

Embodiment 1

[0036] A method for preparing an organic acid molybdenum oil-soluble catalyst for slurry bed hydrogenation, wherein the active component of the organic acid molybdenum oil-soluble catalyst prepared by the preparation method is molybdenum, and the weight content of molybdenum in the organic acid molybdenum oil-soluble catalyst is: 10.52%, its preparation method is as follows:

[0037] (1) Weigh 13.42g of citric acid and add 50mL of distilled water, simultaneously weigh 3.5g of molybdenum trioxide, mix the two fully and pour into a three-necked flask, and stir and react at a constant temperature for 2h at 70°C to obtain a short carbon chain citric acid reaction system;

[0038] (2) Weigh 25.12g of octanoic acid, add dropwise to the short carbon chain citric acid reaction system in step (1), the dropping rate is 3ml / min, and vigorously stir, after the dropwise addition is completed, the temperature is raised to 200°C, and the reaction is continued for 2h to obtain the oil phase f...

Embodiment 2

[0041] A method for preparing an organic acid molybdenum oil-soluble catalyst for slurry bed hydrogenation, wherein the active component of the organic acid molybdenum oil-soluble catalyst prepared by the preparation method is molybdenum, and the weight content of molybdenum in the organic acid molybdenum oil-soluble catalyst is: 4.32%, its preparation method is as follows:

[0042] (1) Weigh 18.42g of oxalic acid and add 50mL of distilled water, simultaneously weigh 3.5g of molybdenum trioxide, mix the two fully and pour into a three-necked flask, and stir and react at a constant temperature for 2h at 70°C to obtain a short carbon chain oxalic acid reaction system;

[0043] (2) take by weighing 15.12g stearic acid, add dropwise the short carbon chain oxalic acid reaction system in step (1), the rate of addition is 3ml / min, and vigorously stir, be warming up to 200 ℃ after the completion of the dropwise addition, continue the reaction 2h to obtain the oil phase part;

[0044]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com