Positive electrode material precursor, positive electrode material, preparation method of positive electrode material and lithium ion battery

A technology of positive electrode materials and precursors, applied in the direction of battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of cumbersome preparation process and limit the development of lithium-ion batteries, and achieve simple manufacturing process, convenient for large-scale production, crystal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a preparation method of the above-mentioned positive electrode material, comprising the following steps:

[0040] The lithium source and the positive electrode material precursor are mixed and then sintered at high temperature to obtain a sintered product;

[0041] The sintered product is annealed, and then ground and sieved to obtain a positive electrode material.

[0042] In the present invention, firstly, the lithium source and the positive electrode material precursor are mixed and then sintered at high temperature to obtain a sintered product.

[0043] In the present invention, the lithium source and the positive electrode material precursor are mixed and placed in a heating device. In the present invention, the heating device is preferably a tube furnace.

[0044] Then, high-temperature sintering is performed in an oxygen or air atmosphere. In the present invention, the high temperature sintering process is divided into two st...

Embodiment 1

[0057] Example 1 Preparation of lithium cobalt oxide layered cathode material

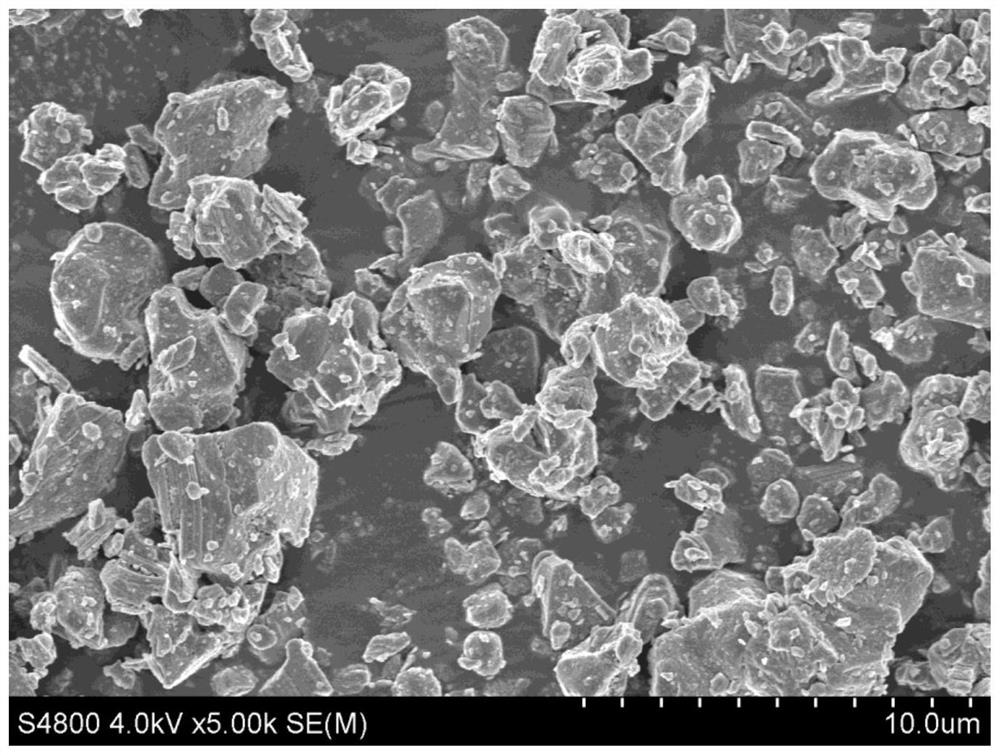

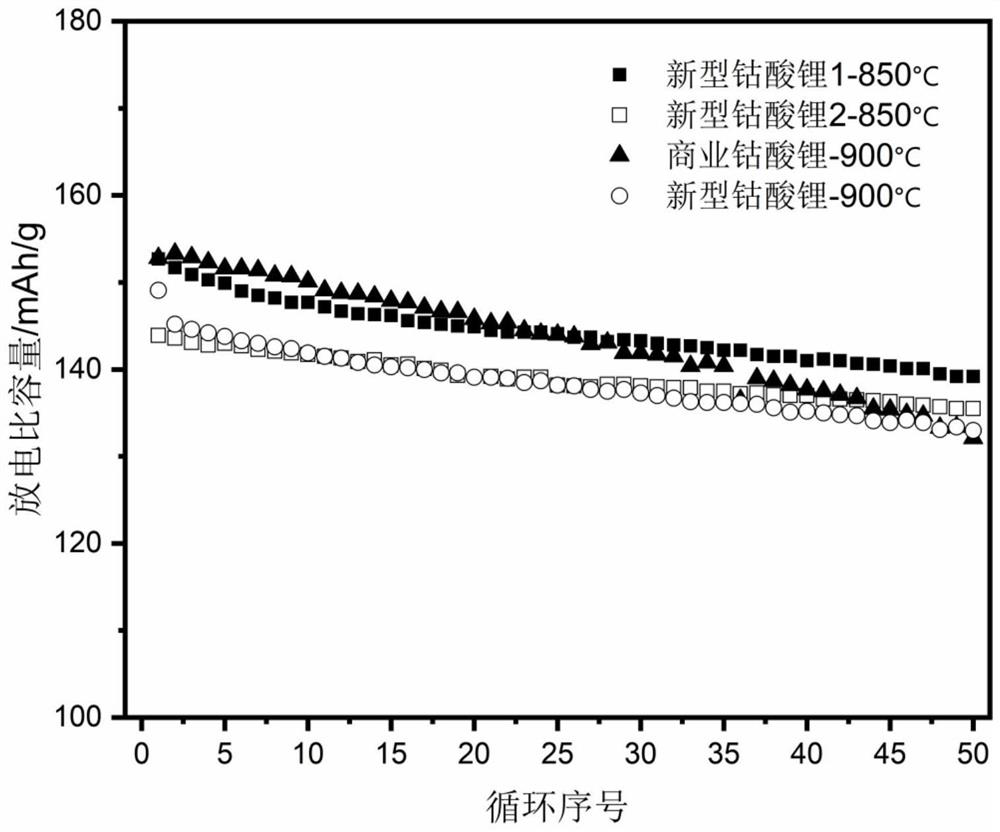

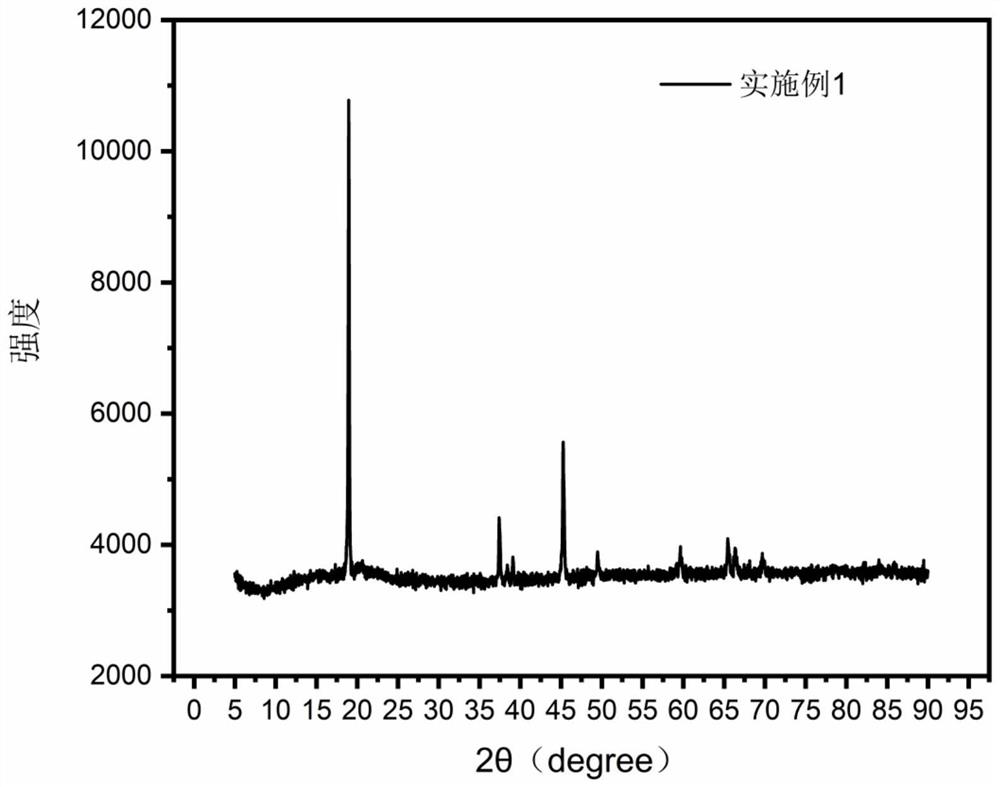

[0058] The cobalt metal elemental powder (particle size is 1 micron) and lithium hydroxide monohydrate are fully mixed according to the molar ratio of 1:1.05, and the mixed powder is placed in a tube furnace, first in an oxygen atmosphere at a rate of 3 °C / min Heating to 500°C for pre-sintering and holding for 5h; then heating to 850°C at a rate of 5°C / min and holding for 10h. After natural annealing in the tube furnace, take out the lithium cobalt oxide cathode material and grind it. After grinding, sieve through a 300-mesh sieve. The sieved lithium cobalt oxide powder is the final product. See Figure 1a , Figure 1a It is a scanning electron microscope picture of the lithium cobalt oxide layered positive electrode material prepared in Example 1. see Figure 1c , Figure 1c It is the xrd pattern of the lithium cobalt oxide layered positive electrode material prepared in Example 1.

[0059] The...

Embodiment 2

[0060] Example 2 Preparation of lithium cobalt oxide layered cathode material

[0061] The cobalt metal elemental powder (particle size is 1 micron) and lithium hydroxide monohydrate are fully mixed according to the molar ratio of 1:1.05, and the mixed powder is placed in a tube furnace, first in an oxygen atmosphere at a rate of 3 °C / min Heating to 500°C for pre-sintering and holding for 5h; then heating to 900°C at a rate of 5°C / min and holding for 10h. After natural annealing in the tube furnace, the lithium cobalt oxide cathode material is taken out and ground. After grinding, it is sieved through a 300-mesh sieve, and the sieved lithium cobalt oxide powder is the final product.

[0062] The above product was mixed with PVDF and carbon black in a ratio of 8:1:1 respectively. The total mass of the mixture was 1 g. After adding 2.3 g of N-methylpyrrolidone, it was fully stirred to obtain a uniform slurry, and the slurry was coated on aluminum foil. After drying, cut the pie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com