Square-meter-level perovskite solar cell module and preparation method thereof

A technology of solar cells and perovskites, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve the problems of limiting the practical commercial application of large-area perovskite solar cells and the inability to form uniform films, and achieve Realize the effects of large-scale application, easy promotion and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

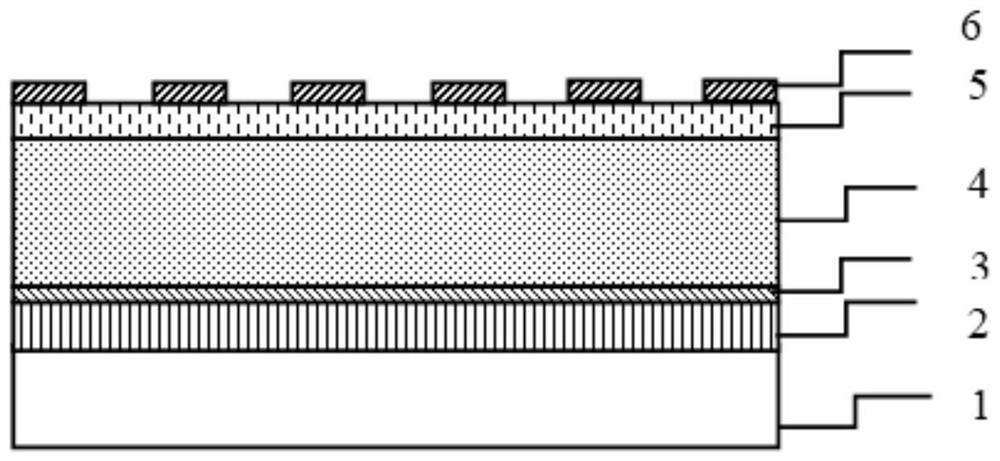

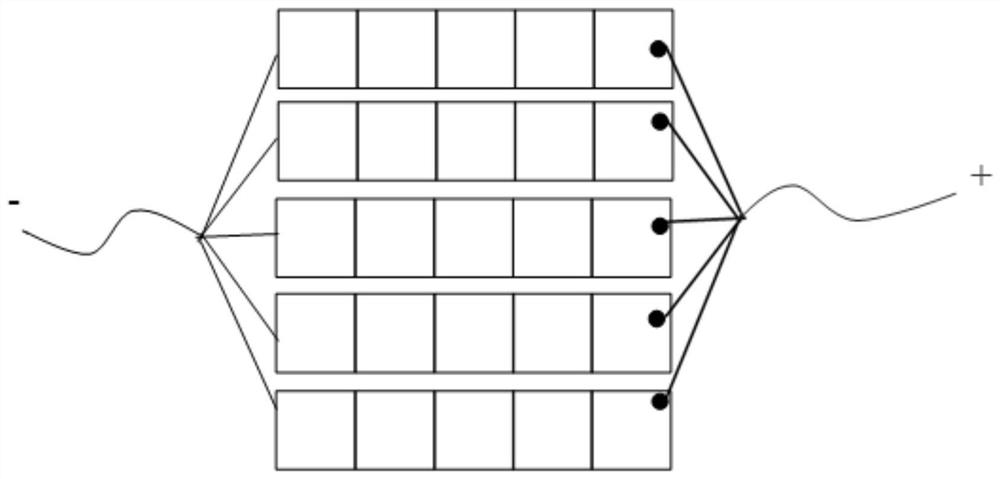

[0036] A square meter-scale perovskite solar cell module is formed by 5 battery cells in parallel, and each battery cell is obtained by connecting 5 perovskite solar cells in series and lamination packaging, wherein the schematic diagram of the perovskite solar cell structure is as follows figure 1 As shown, its preparation method comprises the following steps:

[0037] Step 1. Treatment of metal substrate 1: Use rough stainless steel metal plate as the base material, cut it into 10cm×10cm size after polishing, and then use dilute hydrochloric acid, soapy water, deionized water, and ethanol to ultrasonically clean for 15 minutes each, and use nitrogen after the end. Flow drying, the thickness of the metal substrate 1 is 0.2mm;

[0038] Step 2: Prepare the bottom electrode 2: Divide the treated metal substrate 1 into 25 uniform regions, each with a size of 2cm×2cm, and select one of the regions to form the bottom electrode 2 by magnetron sputtering titanium metal. The process ...

Embodiment 2

[0048] A square meter-scale perovskite solar cell component, the preparation method comprising the following steps:

[0049] Step 1. Treatment of metal substrate 1: Use rough stainless steel metal plate as the base material, cut it into a size of 20cm×20cm after polishing, and then use dilute hydrochloric acid, soapy water, deionized water, and ethanol to ultrasonically clean for 15 minutes each, and use nitrogen after the end. Flow drying, the thickness of the metal substrate 1 is 0.2mm;

[0050] Step 2: Prepare the bottom electrode 2: Divide the treated metal substrate 1 into 100 uniform regions, each with a size of 2cm×2cm, and select one of the regions to form the bottom electrode 2 by magnetron sputtering titanium metal. The process is as follows: in the vacuum chamber of the magnetron sputtering coater, using argon (Ar) as the working gas, through the method of DC sputtering, ions bombard the titanium target to deposit a layer of titanium film on the surface of the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com