Preparation method of nano copper selenide

A copper selenide, nanotechnology, applied in the direction of chemical instruments and methods, binary selenium/tellurium compounds, copper compounds, etc., can solve the problems of high cost, product agglomeration, high risk, etc., and achieve low cost and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

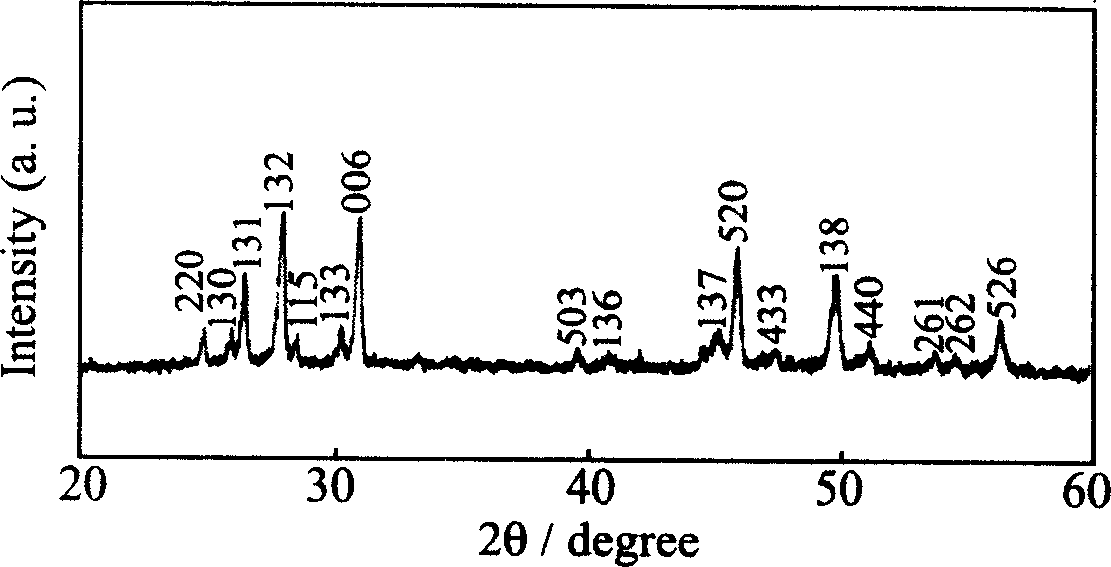

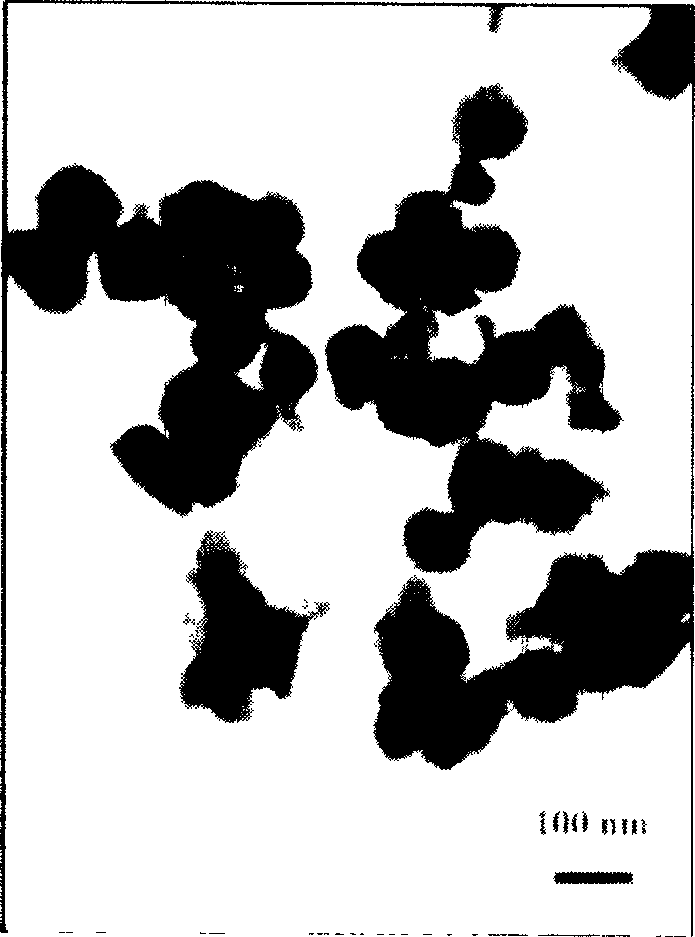

Image

Examples

Embodiment 1

[0018] ①In a 50mL quartz Erlenmeyer flask, dissolve 0.2g copper nitrate in 26mL deionized water, add disodium edetate at a molar ratio of 1:1 to obtain divalent copper ions and edetate di Sodium complexes——aqueous solution of ethylenediaminetetraacetic acid and copper complex anions.

[0019] ② Dissolve 0.06 mol of anhydrous sodium sulfite in 100 mL of deionized water, then add 0.02 mol of selenium powder, and reflux for 5 hours to obtain a 0.2 M aqueous sodium selenosulfate solution.

[0020] ③ Measure 4mL of the sodium selenosulfate aqueous solution prepared in step ② and add it to the aqueous solution of ethylenediaminetetraacetic acid copper complex anion prepared in step ①, pass nitrogen gas for 15 minutes, and then place the Erlenmeyer flask in a 250W high-pressure mercury lamp Irradiate at a distance of 20 cm for 4 hours, and use cooling water to keep the reaction system at room temperature. The obtained product was centrifuged, washed three times with deionized water,...

Embodiment 2

[0023] ①In a 50mL quartz Erlenmeyer flask, dissolve 0.2g of anhydrous copper sulfate in 26mL of deionized water, and add disodium edetate at a molar ratio of 1:1.2 to obtain divalent copper ions and ethylenediaminetetra Complexes of disodium acetate—aqueous solution of ethylenediaminetetraacetic acid and copper complex anion.

[0024] ② Dissolve 0.05 mol of anhydrous sodium sulfite in 100 mL of deionized water, then add 0.02 mol of selenium powder, and reflux for 5 hours to obtain a 0.2 M aqueous sodium selenosulfate solution.

[0025] ③ Measure 3 mL of the sodium selenosulfate aqueous solution prepared in step ② and add it to the aqueous solution of ethylenediaminetetraacetic acid copper complex anion prepared in step ①, pass nitrogen gas for 20 minutes, and then place the Erlenmeyer flask in a 250W high-pressure mercury lamp Irradiate at a distance of 20 cm for 4 hours, and use cooling water to keep the reaction system at room temperature. The obtained product was centrifug...

Embodiment 3

[0027] ①In a 50mL quartz Erlenmeyer flask, dissolve 0.2g copper chloride in 26mL deionized water, add disodium edetate at a molar ratio of 1:1.5 to obtain divalent copper ions and edetate Disodium complexes - ethylenediaminetetraacetic acid copper complex anion aqueous solution.

[0028] ② Dissolve 0.06 mol of anhydrous sodium sulfite in 100 mL of deionized water, then add 0.02 mol of selenium powder, and reflux for 4 hours to obtain a 0.2 M aqueous sodium selenosulfate solution.

[0029] ③ Measure 4 mL of the sodium selenosulfate aqueous solution prepared in step ② and add it to the aqueous solution of ethylenediaminetetraacetic acid copper complex anion prepared in step ①, pass nitrogen gas for 30 minutes, and then place the Erlenmeyer flask in a 250W high-pressure mercury lamp Irradiate at a distance of 20 cm for 8 hours, and use cooling water to keep the reaction system at room temperature. The obtained product was centrifuged, washed three times with deionized water, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com