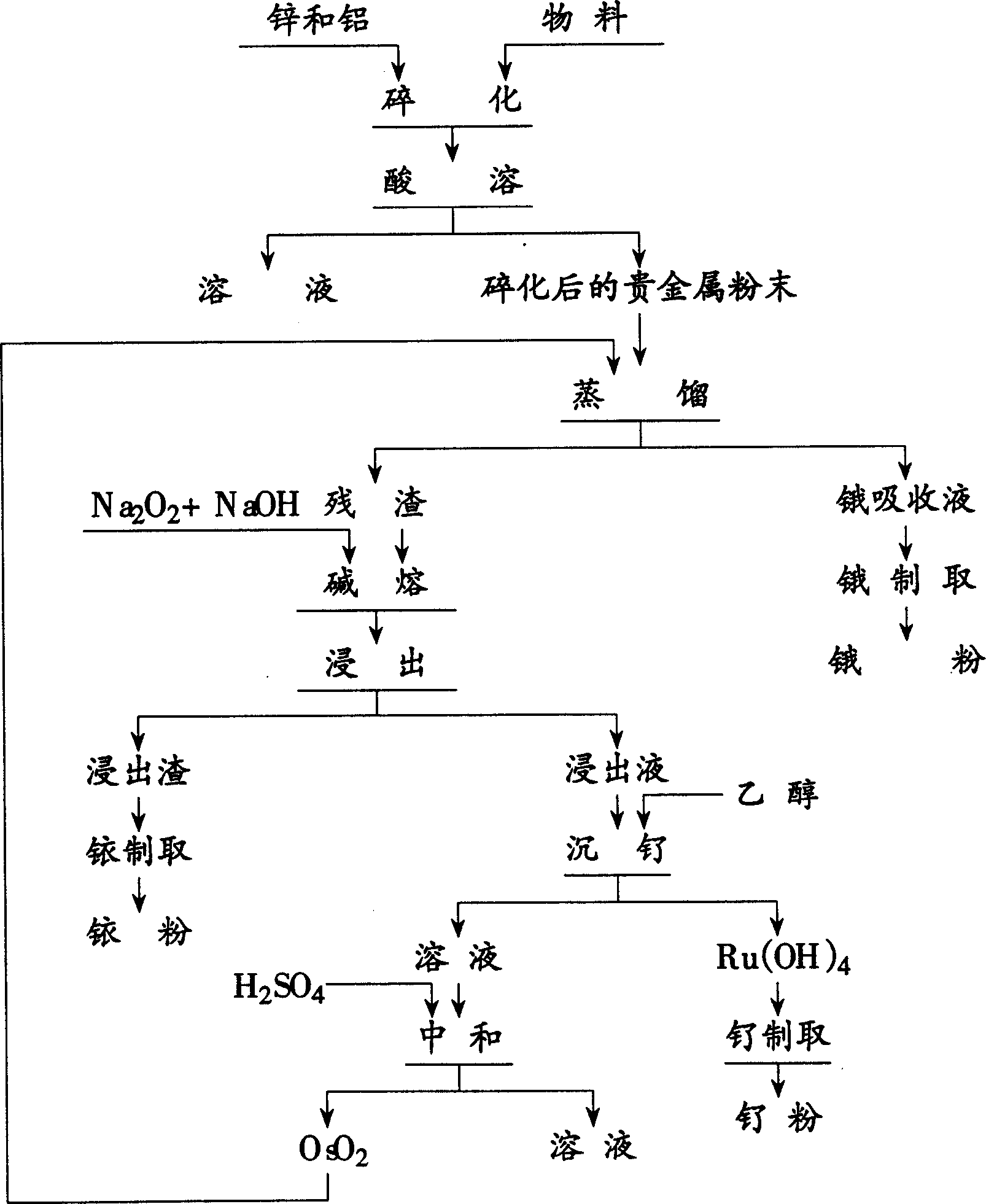

Method for extracting osmium, iridium and ruthenium

A fire method and solution technology, applied in the field of metallurgy, can solve the problems of large reagent consumption, poor ruthenium distillation effect, entering the solution, and leaving the other part in the slag, so as to reduce the consumption of reagents, reduce processing costs, and achieve good crushing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] A certain iridium osmium ore, its main components are (%):

[0056] Os: 42.3, Ir: 35.1, Ru: 15.5, Au: 0.41, Pd: 0.43

[0057] Put 1.0Kg of iridium-osmium ore with the above ingredients into an alloy melt of 3Kg zinc and 0.5Kg aluminum melted at 500°C, stir, keep warm at 500°C for 1 hour, raise the temperature to 750°C and keep warm for 0.5h, stir, and keep warm for 0.5h , the melt is poured into a stainless steel barrel with 60L water for water quenching; gradually add industrial hydrochloric acid to the water quenching alloy block, and filter out the solution that has dissolved zinc and aluminum, add industrial hydrochloric acid again and heat to 80°C, hydrochloric acid The total dosage is 25L; filter and wash with water until neutral, put the crushed powder into the quartz boat and push it into the tube furnace, connect the osmium absorption system, and turn on the water ring vacuum pump to pump at a speed of 10L / min. Gas, the tube furnace containing the material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com