Method for preparing ceramic coating layer

A ceramic coating and ceramic technology, which is applied in chemical instruments and methods, catalyst activation/preparation, pressure inorganic powder coating, etc., can solve the problems of large thermal influence of structural changes on the substrate, and achieve the effect of superior structure and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: see figure 1 , figure 1 It is a photo of the appearance of the titanium oxide block powder involved in the implementation of the present invention. The powder is a bulk titanium oxide powder produced by a smelting and crushing method, which has a polygonal shape and a rutile crystal structure.

Embodiment 2

[0028] Example 2: see figure 2 . figure 2 A photograph of the morphology of the titanium oxide agglomerated powder doped with iron oxide involved in the implementation of the present invention. The powder is composed of anatase TiO with a diameter of 0.2 μm 2 Micronized and added with 10% Fe 3 o 4 The particles are composite powders produced by spray granulation method, the powder is spherical, and the mechanically doped Fe in it is confirmed by DAX analysis 3 o 4 The particles are evenly distributed in the powder.

Embodiment 3

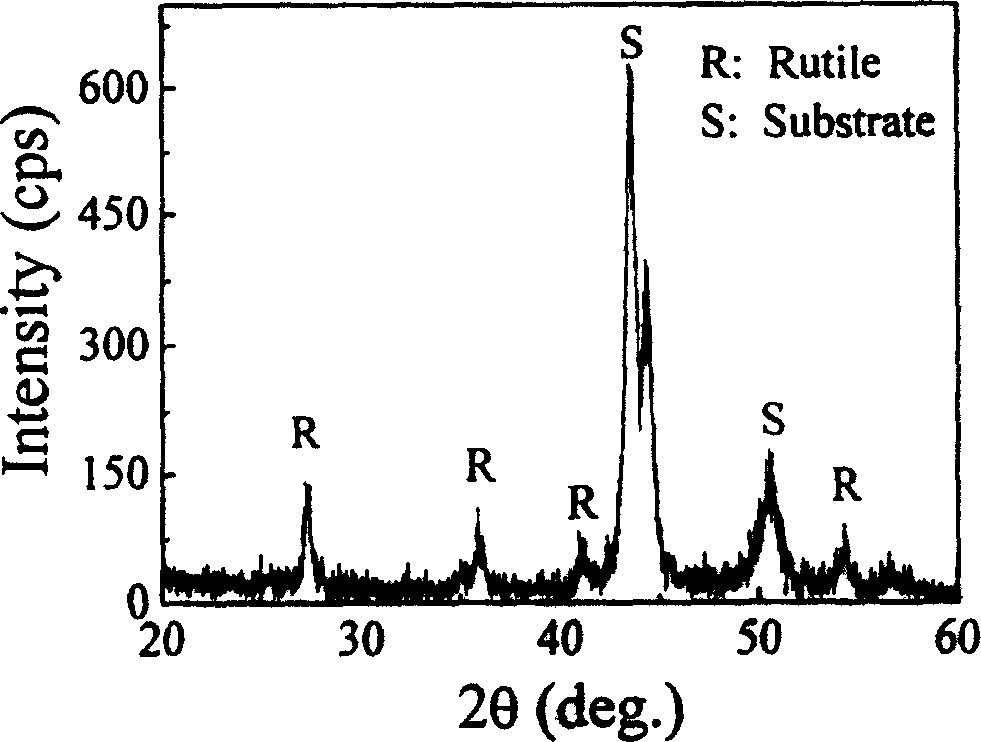

[0029] Embodiment 3: see image 3 . image 3 X-ray diffraction pattern of titanium oxide photocatalytic coating prepared by using titanium oxide bulk powder. Using the powder described in Example 1, according to the idea of the present invention, a titanium oxide ceramic photocatalytic coating is prepared on a stainless steel substrate, and the crystal structure of the coating is rutile, which is consistent with the original powder, that is to say, the process will The crystal structure of the powder is almost completely transferred into the coating. The photocatalytic degradation of phenol in water and acetaldehyde in gas by using the coating shows that the coating has good photocatalytic performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com