Composite material comprising photocatalyst and phenolic resin group active carbon and preparation method thereof

A technology of photocatalyst and phenolic resin, which is applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc. It can solve the problems of affecting the efficiency of photocatalyst decomposition of organic poison, reducing the surface area of porous substances, and large consumption of oxidant. , to achieve the effect of increasing the catalytic surface area, low price and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

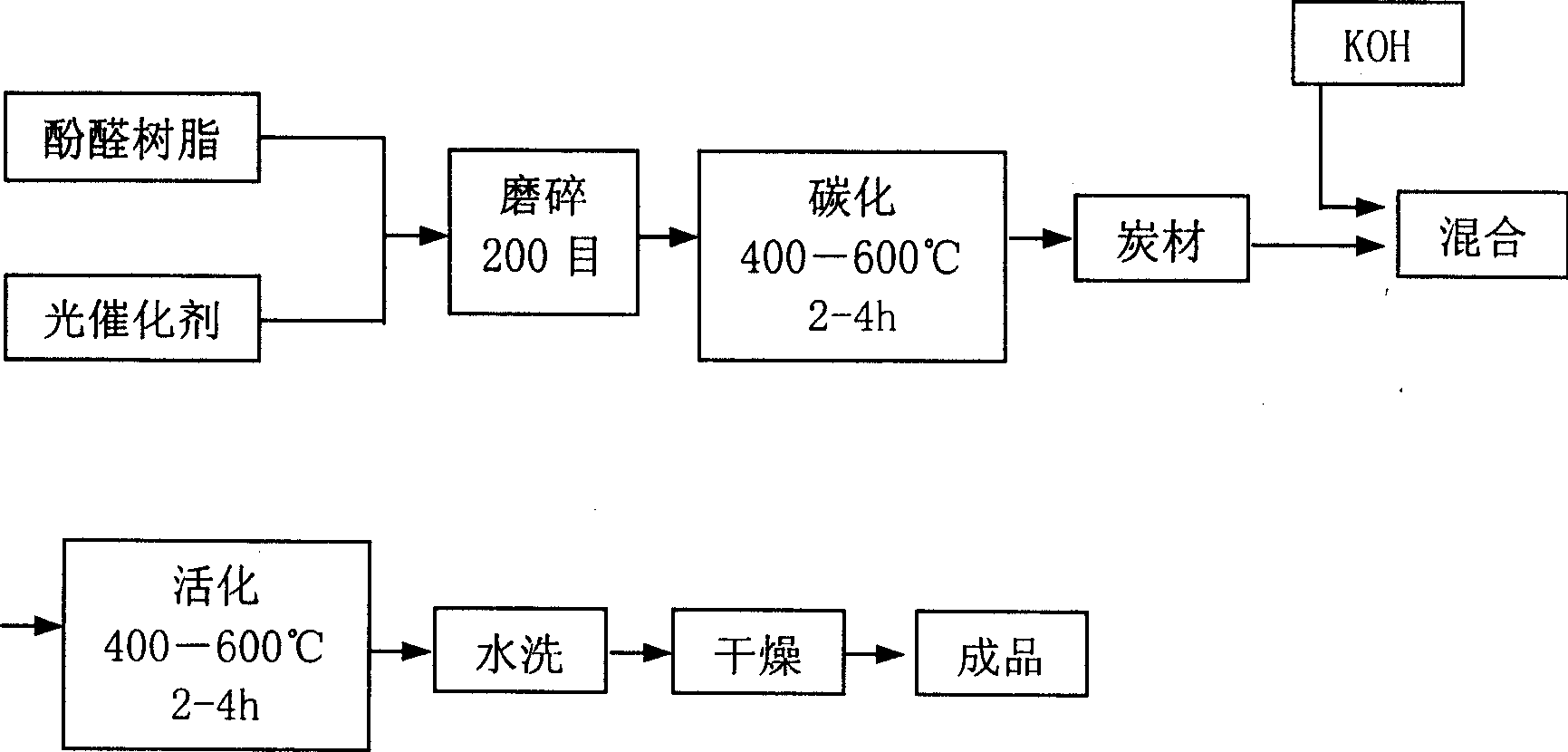

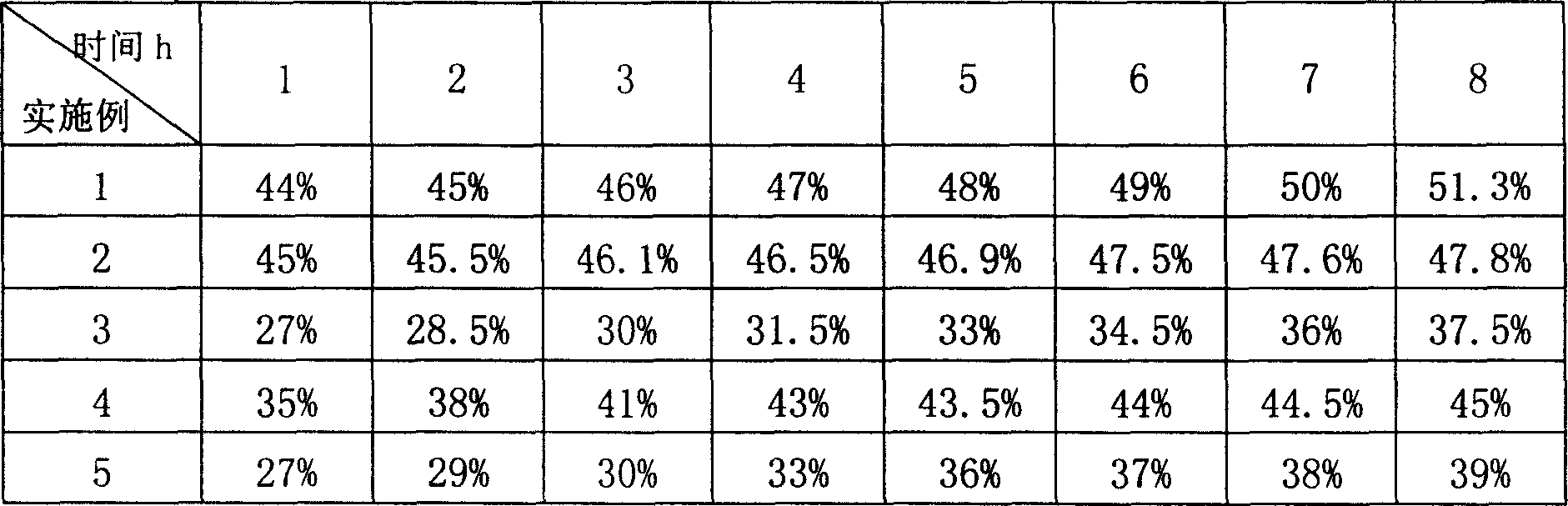

[0022] Embodiment 1: get 70 parts by weight of novolak resin powder by weight, photocatalyst (TiO 2 ) 35 parts by weight of micropowder, 70 parts by weight of activator (KOH). The phenolic resin powder is mixed with the photocatalyst micropowder, ground into a container after 200 mesh sieves, and carbonized at 500° C. for 3 hours under nitrogen protection. The carbon material obtained above is mixed with 35 parts by weight of an activator (KOH ), fully mixed, put into a container, and activated under nitrogen protection at 550°C for 2 hours. In the wastewater containing phenol, add the photocatalyst composite material identical with the weight of phenol and stir evenly, under ultraviolet light (intensity 53w / m 2 ), and irradiated for 8 hours, the measured amount of decomposition of phenol (the amount of decomposition of phenol) reached more than 51.3%. The results are shown in Table 1.

Embodiment 2

[0023] Embodiment 2: get 70 parts by weight of novolac resin powder by weight, photocatalyst (WO 3 ) 35 parts by weight, 35 parts by weight of activator (zinc chloride), press the manufacturing process method of the photocatalytic composite material of implementing 1, can obtain, photocatalyst (WO 3 ) composite material, according to the method for the treatment of phenol-containing waste water of embodiment 1, the decomposition amount of measuring phenol can reach 47.8%, the results are shown in Table 1.

Embodiment 3

[0024] Embodiment 3: get 100 weight parts of novolac resins by weight, photocatalyst (TiO 2 ) 10 parts by weight, 100 parts of activator (KOH), 5 parts of zinc chlorides, press the manufacturing process method of the photocatalyst composite material of embodiment 1, can obtain photocatalyst (TiO 2 ) composite material, the decomposition amount of phenol can reach 37.5% as measured by the method for the treatment of phenol waste water of embodiment 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com