TiO2 non-linear pressure-sensitive ceramic resistor and its preparation method

A technology of varistor ceramics and resistors, which is applied in the field of TiO2 non-linear varistor ceramic resistors without Bi and Pb and its preparation. Effects of cracking, prolonging motor life, and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

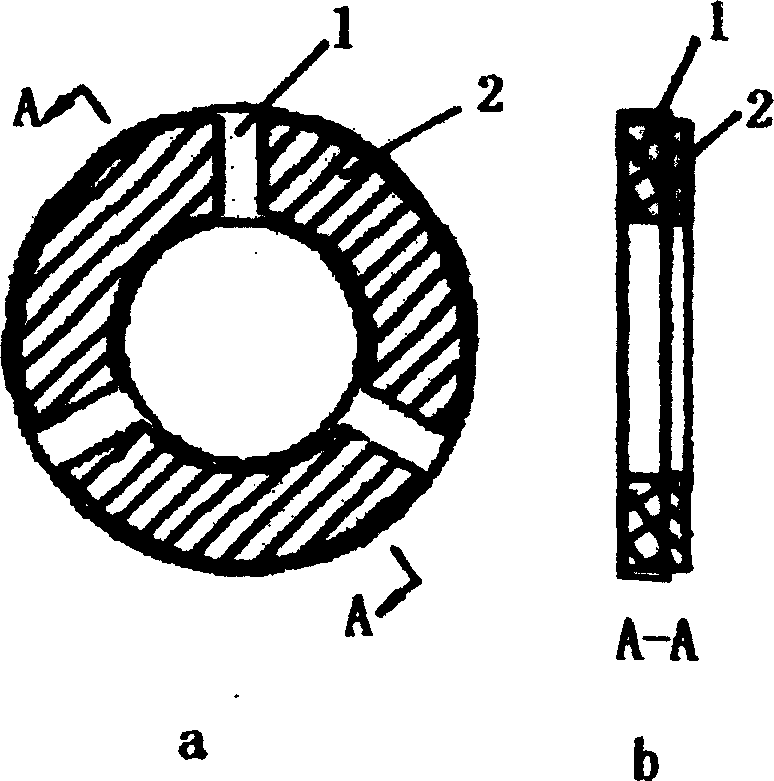

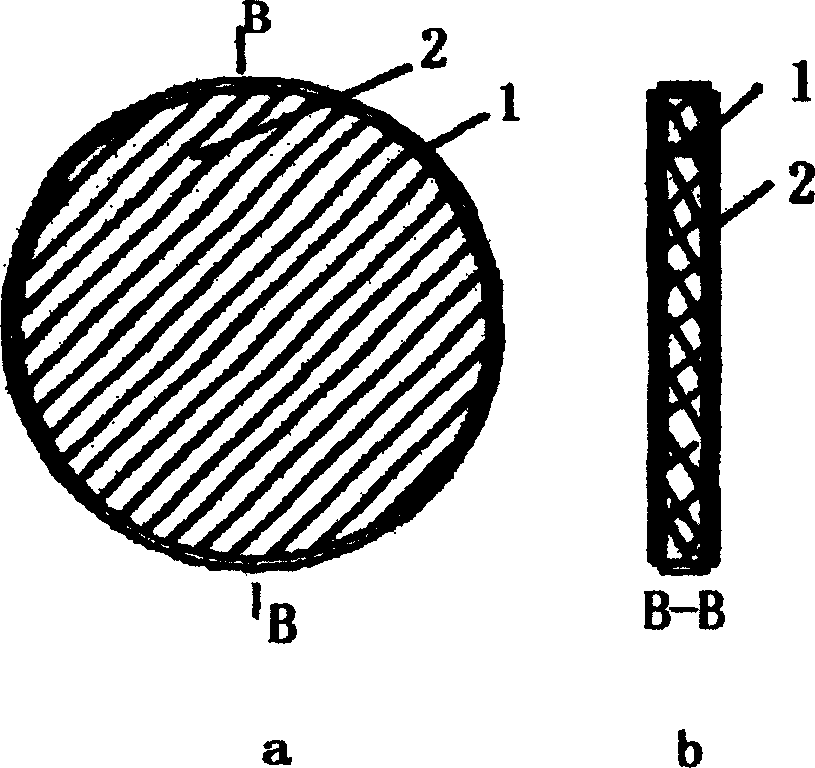

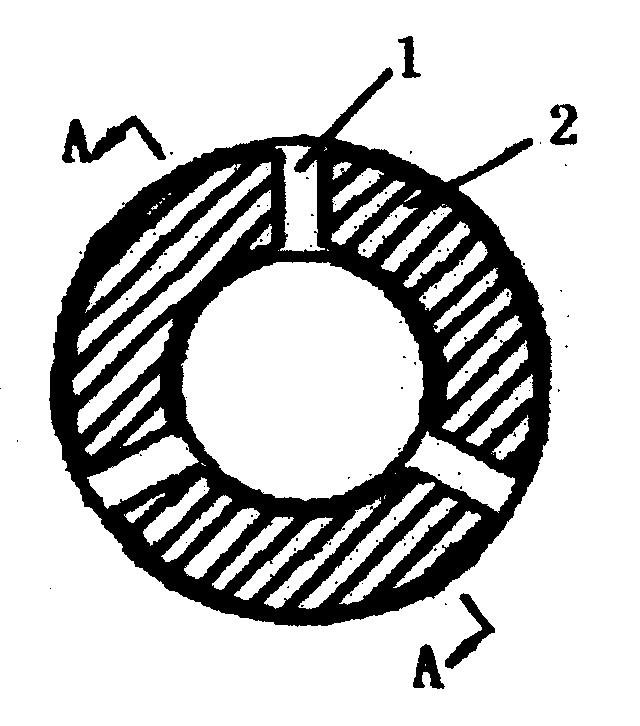

Image

Examples

preparation example Construction

[0021] The preparation method of the nonlinear varistor ceramic resistor is:

[0022] 1) Weigh the required raw materials according to the value range of x and y in the ceramic substrate, and carry out the mixed ball milling process to the raw material powder according to the conventional method, so that the particle size of various powder raw materials is less than 2 microns;

[0023] 2) Sieve the ball-milled mixed powder, manually granulate or spray granulate the ball-milled and sieved powder, and sieve the granulated powder to shape the granulated and sieved powder;

[0024] 3) The formed embryo body is fired at 600°C to 1120°C to remove the organic binder and make it have a certain strength;

[0025] 4) The green body that has been fired to remove the organic binder is sintered in the air, the temperature is between 1050°C-1450°C, and the sintering time is between 0.5-10 hours; the partial pressure of oxygen during sintering is not less than 0.2 atmospheres .

[0026] 5)...

Embodiment 1

[0030] Embodiment 1, garden flake-shaped sample

[0031] Using industrial reagent pure TiO 2 , additive Nb 2 o 5 , CeO 2 and sintering aid SiO 2, mixed according to the composition in Table 1, planetary milling 250 rpm, ball milling for 5 hours, drying, granulation, 150MPa dry pressing to form a disc-shaped embryo body with a diameter of 10mm and a thickness of 1.2mm, after 600℃~1120℃ Accompanied firing removes organic binders and imparts strength. Sintering at 1350°C in the air, heat preservation for 4 hours, one-time firing, 2-3 layers of samples stacked, and calcined TiO 2 Powder as padding. The two sides of the ceramic chip are fired with Ag electrodes, and the silver is fired at 580°C for 15 minutes. The sample is measured with a piezoresistor DC parameter measuring instrument for V 1mA , Measure capacitance C and loss tgδ with LCR digital electric bridge.

[0032] The contents of Nb and Si are fixed, and the content of Ce is changed from 0 to 5.0mol%. The electr...

Embodiment 2

[0036] What is to be done in Example 2 is to compare samples 1-5 in Example 1 with samples obtained by changing the sintering regime.

[0037] Fix other parameters, such as reagent ratio, carry out all the processes as in Example 1, the difference is the change of sintering system as shown in Table 2, including sintering temperature and holding time, at 1300 ° C ~ 1400 ° C × 2h ~ 4h At the sintering temperature of , the samples made were measured similarly to those in Example 1. The results are shown in Table 2.

[0038] This example shows that the influence of sintering temperature and holding time on the comprehensive electrical properties of the sample is not linear. The voltage V of samples 2-3 1mA , nonlinear characteristics and relative permittivity and loss are in the best balance. The composition and firing regime of this sample are then optimal in the present invention.

[0039] Sample

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com